User2User 2024: Pioneering semiconductor reliability automotive apps – imec’s Canary chip

In this User2User 2024 presentation, Dr. Thomas Kallstenius, representing imec, the world’s leading independent research institute specializing in nanoelectronics, whose Belgium-based R&D hub delved into the innovative technology of Canary chips developed by imec. Thomas explains how Canary chips can predict and monitor degradation and tampering in various electronic components with a particular focus on automotive applications. The presentation also highlighted the potential benefits for industries like data centers, aerospace, and medical devices.

What is a Canary chip?

The Canary IC chip is ingeniously named after the historical use of Canaries in coal mines—these small birds served as early warning signs for miners by detecting dangerous levels of carbon monoxide. Just as the Canaries’ sensitivity to toxic gases once safeguarded human lives, the Canary Chip monitors the health of electronic systems, alerting users to potential degradation or tampering. Its role is to preemptively signal the need for intervention, protecting systems from harm. This monitoring chip, versatile and unobtrusive due to its negligible power requirements, can be integrated into various components, microcontrollers, and chips, paired with a Canary Controller to communicate alerts. Positioned to be a silent guardian, the Canary IC chip is a modern nod to an age-old safety measure, revamped for the digital era’s complex circuitry.

Canaries predict failures on the chip level!

Monitoring the health and status of microchips or microcontrollers inside devices like your mobile phone is very difficult compared to just checking the battery level. However, as Thomas explains, being able to do this “chip monitoring” would be really useful for a few reasons. First, it enables predictive maintenance – being able to foresee when a chip might fail and proactively repair or replace it before it causes bigger issues. This is valuable for industries like automotive, data centers, aerospace, medical devices, etc. where failure is critical. Second, you can optimize the chip’s performance by slowing it down if it’s showing signs of degradation, extending its usable lifetime. Third, understanding a chip’s remaining lifespan allows for reusing and reselling components instead of discarding them, which is better for the environment. While labeling individual chips may not work, providing lifespan estimates for larger components like automotive control units could enable this reusability.

Example: Enabling Predictive Chip Maintenance in Automotive

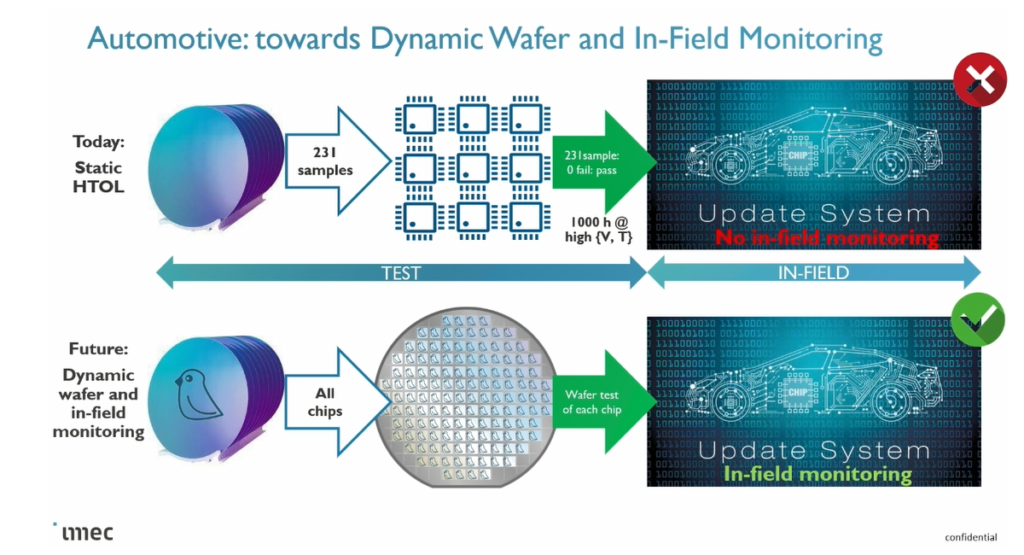

In automotive today, chips go through testing like High Temperature Operational Life (HTOL) testing on a sample set before being approved for use. Once approved and installed in vehicles, there is no further monitoring of the chips during their actual operational life in the field.

With Canary chips monitoring:

- During manufacturing, all chips can be tested instead of just a sample set, providing better quality control.

- Once installed in the vehicle, the Canary monitors embedded in the chips can continuously monitor for degradation mechanisms like bias temperature instability and hot carrier effects.

- If degradation starts occurring during the vehicle’s operational life, the Canaries can detect this and provide early warning before actual chip failure.

- This enables predictive maintenance – being able to replace degraded chips before they fully fail, improving vehicle reliability and safety.

- It is especially useful for mission-critical automotive subsystems like engine/powertrain control, ADAS, etc that use advanced semiconductor nodes more prone to degradation effects.

The Canary monitors allow unprecedented in-field visibility into chip health and degradation, enabling proactive replacement and optimizing vehicle reliability – something not possible with just upfront testing today.

The Canary monitoring ecosystem

The Canary solution also includes the Canary Library software component that performs the degradation analysis. This library can connect to external process, voltage, and temperature (PVT) monitors as well as to a potential future cloud service for data collection and analysis. The hardware component called the Canary Controller, has been taped out and successfully validated across multiple semiconductor process nodes – 28nm planar, 16nm FinFET, with 5nm FinFET and others in progress. Porting the Canary monitors to new process nodes only requires calibrating a few parameters as the underlying degradation physics remains the same. Live demos show the Canary monitors can accurately track chip degradation by measuring the frequency shift in their embedded ring oscillators when stressed, following the expected degradation curves. This integrated hardware-software solution provides a robust “odometer” for reliably monitoring chip lifetime and degradation.

“Canaries and Canary technology will change very much the way we look at degradation of chips and degradation of integrated circuits and systems on the chips in the future”

Dr. Thomas Kallstenius, representing imec,

Summary

Watch this video to learn more about how Canary technology represents a paradigm shift in how we monitor and manage chip degradation throughout the lifecycle – from testing to field operation. This innovative solution provides a robust, physics-based “odometer” for reliably tracking chip lifetime and degradation. It is uniquely enabled by imec’s secure and tamper-evident Canary IP, which is design-agnostic and optimized specifically for in-field monitoring of chips during operational use.

If you missed User2User 2024 or attended the event and want to watch the 3DIC sessions again, the library of videos is now available on-demand here: Click here

To learn more about Siemens EDA 3DIC solutions, visit our 3DIC Homepage