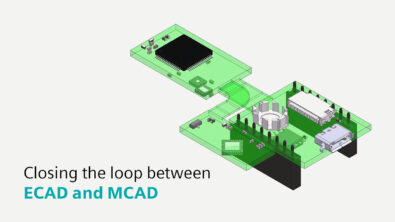

Closing the loop between ECAD and MCAD: seamless ECAD-MCAD collaboration through IDX and Xpedition

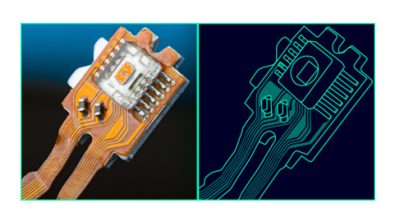

Every modern product relies on ECAD-MCAD collaboration, yet those disciplines often work in isolation, creating bottlenecks when designs must come together. Designers must define board shape precisely with mechanical enclosures, cooling strategies, and product form-factors that were not possible a decade ago. PCB outlines now incorporate curves, rigid-flex stackups, and edge connectors that even seasoned designers often have trouble conveying design intent.

With Xpedition Standard, ECAD-MCAD collaboration comes built in, enabling real-time data exchange and synchronized design intent across domains. With Xpedition Standard, ECAD-MCAD collaboration comes built in, enabling real-time data exchange and synchronized design intent across domains. The Advanced ECAD-MCAD collaboration add-on builds on that foundation with deeper synchronization and domain-specific 3D context

The challenge of disjointed design data: ECAD and MCAD

Historically, the electrical (ECAD) and mechanical (MCAD) design domains have operated in silos with disjointed design data:

- Missed clearances: Mechanical or electrically-driven changes are often missed, resulting in physical collisions or component placement issues.

- Delayed communication: Files and emails shuffle back and forth, leading to misunderstandings, missed requirements, and time-consuming alternations.

- Manual data synchronization: Without robust data exchange, teams waste precious time reconciling diverging models and design intent, often only to discover late-stage violations that require costly rework.

Enter IDX: A modern framework for co-design

Xpedition Standard enables ECAD-MCAD collaboration leveraging the IDX open exchange schema; a significant leap beyond legacy file format exchanges like IDF, STEP, and parasolid. IDX isn’t just a file format – it’s a communication protocol that captures intent as well as geometry.

Xpedition Standard ECAD-MCAD collaboration enables:

- Real-time design intent flow: Teams can exchange rich, incremental design updates; never just static snapshots or renderings.

- Change traceability: Every update is annotated, differences are charted, and notes are embedded directly in the shared IDX file.

- Visual decision-making: Updates can be graphically reviewed, interrogated, and critically Accepted or Rejected by either domain.

- Continuous synchronization: Mechanical and electrical data stay tightly aligned throughout the project, not just at major milestones.

The workflow: how Xpedition enables ECAD-MCAD collaboration

By default, Xpedition empowers an interactive, disciplined design data exchange. The advanced ECAD-MCAD collaboration add-on enables sharing additional design intent information, such as assembly variants and domain-specific 3D models.

Here’s how a typical co-design process unfolds:

1. Establish the baseline

The mechanical engineer defines the enclosure, board outline, holes, and keep-outs, then exports a ‘baseline’ IDX file.

2. Sync to ECAD

The ECAD designer imports the baseline into Xpedition, instantly synchronizing PCB and mechanical models and requirements.

3. Collaborate and respond

The ECAD designer sends a ‘response’ file, confirming acceptance and readiness for further collaboration.

4. Incremental proposals

Both ECAD and MCAD may propose design changes (incremental IDX updates). For instance, the MCAD engineer moves a mounting hole, or the ECAD designer adjusts component layout.

5. Review and decision

Each proposal is reviewed. Differences are reported, annotated, and visualized. Most importantly, engineers may accept or reject proposals, preserve design intent, and prevent errors.

6. Iterate and innovate

The cycle repeats as often as needed, agile, interactive, and synchronized, until the design reaches signoff, free of costly surprises.

Why should I use Xpedition with advanced ECAD-MCAD collaboration?

- Faster time-to-market: Early detection of issues means less rework and more engineering focus on next-generation projects.

- Integrated digital thread: Synchronizes ECAD and MCAD data, preserving the ‘why’ behind every design decision.

- Effortless compliance: Automatic tracking and reporting ease regulatory and quality validation.

- Scalable collaboration: From individuals to global enterprises, Xpedition grows to fit your process, budget, and design intent.

With Xpedition Standard and advanced ECAD-MCAD collaboration, you’re not just resolving ECAD-MCAD conflicts; you’re creating a shared environment where design intent flows freely, decisions are traceable, and innovation accelerates without friction.

The result: No more lost emails, no more hidden collisions, no more guesswork; just PCB design collaboration that brings your best products to life, faster.

Discover more

Learn how you can experience seamless ECAD-MCAD collaboration with Xpedition Standard and Advanced ECAD-MCAD collaboration.