DFM: Still a really good thing to do!

By Simon Favre

If you’re not using critical area analysis and design for manufacturing to improve your IC yield and quality…why not? Especially when all the details are right here…

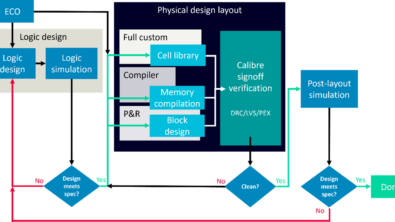

As every designer knows, having a design that passes all the required verification checks isn’t quite enough to guarantee market success and profitability. Design optimization is the art and science of refining a design to ensure you squeeze every last nanometer of usability out of the available area, and that you have done everything you can to remove all impediments to high performance, high reliability, and a successful yield.

Critical area analysis (CAA) and design for manufacturing (DFM) scoring are two strategies used by fabless designers, foundries, and integrated device manufacturers to minimize manufacturing susceptibilities and maximize physical reliability before actual production begins. If you’re not already using these two strategies, you’re either a certified design genius, or you’re missing out on opportunities to get the most from your designs.

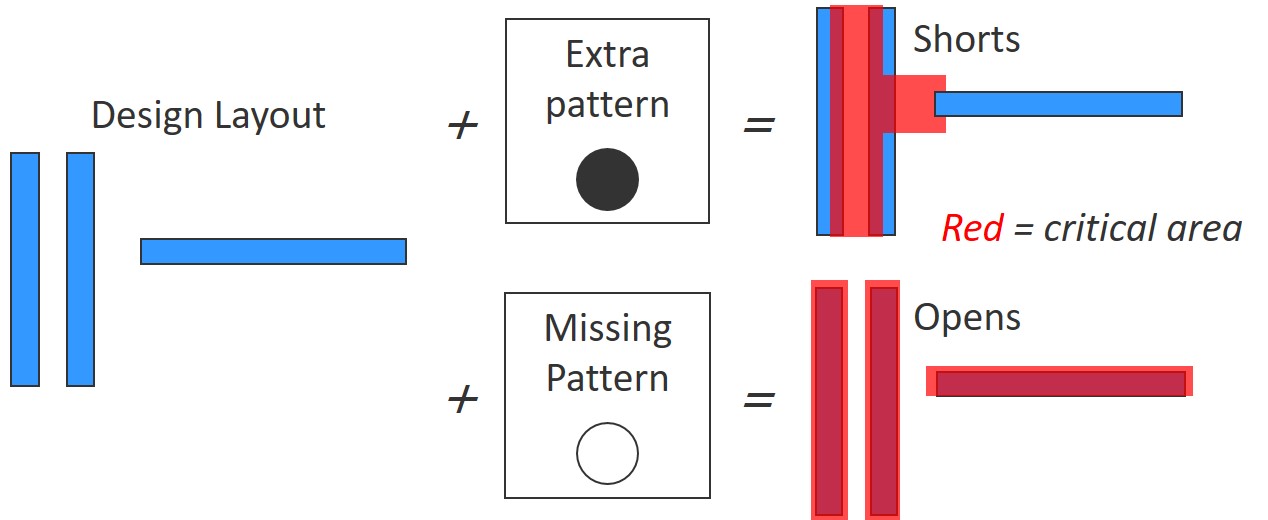

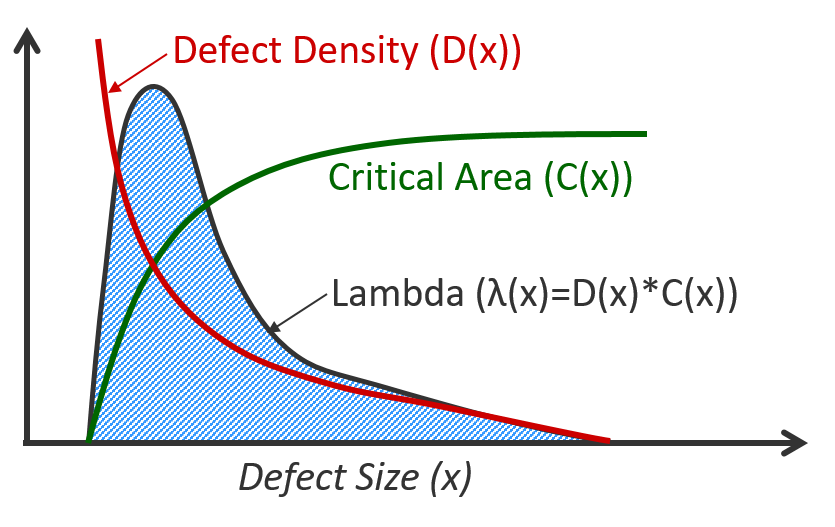

Designers use CAA to predict defect-limited yield before tape-out by identifying potential random defect sensitivity in a layout. CAA can also be the catalyst for future process improvements by reporting those layers and defect types to which typical designs are most sensitive, giving design teams a chance to rework those areas in future designs.

DFM scoring gives layout designers actionable reports that enable them to apply DFM optimization to the layers and rules that are likely to return the greatest benefit. DFM scoring decks can also provide optimization hints that point designers toward the “best” alterations to make in the layout, or even automatically apply improvements that the designers can review and merge into the layout to improve their designs.

Foundries use both CAA and DFM scoring to screen incoming designs and ensure they have been fully optimized for design and manufacturing yield. Some foundries even use CAA to drive optical metrology equipment, so that the most detailed inspection effort is applied in the locations where the design has hotspots.

The Calibre® YieldAnalyzer tool supports a full range of both CAA and DFM scoring techniques. Whether you’re using a leading-edge process node to manufacture a very large system on chip (SoC), or an established node for automotive or internet of things (IoT) designs, applying CAA and DFM scoring with the Calibre YieldAnalyzer tool can help you improve the manufacturability, reliability, and ultimately the profitability, of your products. Obviously, a good thing to do.

If you’d like to see more of the details, they’re all in our white paper: Using CAA and DFM scoring to improve manufacturing success