What does it take to build electric vehicles?

On behalf of Nilesh Wani – Siemens Digital Industries Software

The automotive industry faces many challenges today. Key among them is the transition to electric vehicle platforms for both new and existing products. Many existing automotive manufacturers are establishing their adoption of electric vehicle (EV) technology while many new entrants are developing EVs from the ground up. All have their sights set on meeting the expected demand for these new vehicles in the future as dictated by automotive market trends and emerging new business models.

The adoption of new EV technologies is still low as compared to internal combustion engine (ICE) powered vehicles. Hence, all automotive original equipment manufacturers (OEMs) face the hurdle of starting with low volume production and increasing it over a period. While doing this they must optimize their capital investments.

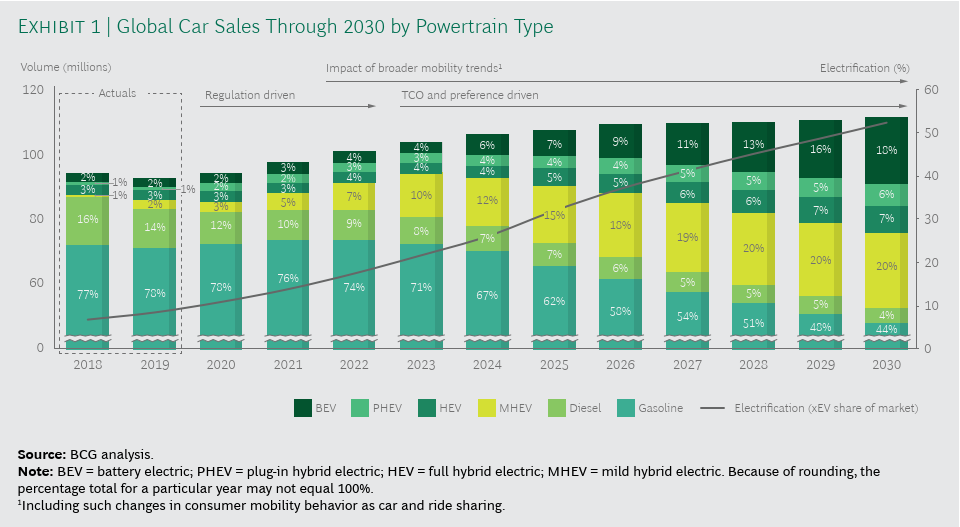

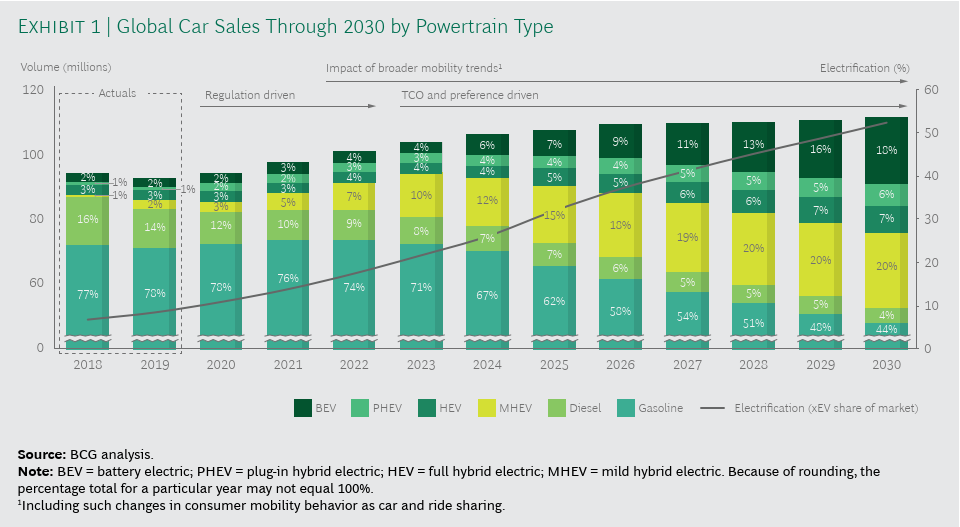

According to Boston Consulting Group, EVs are on pace to capture around 50% of new vehicle sales by 2030.

Source: Who Will Drive Electric Cars to the Tipping Point? – BCG Report, January 2020

Furthermore, according to a McKinsey & Company report, although global auto sales plunged during the COVID-19 crisis electric mobility has remained remarkably resilient in some countries, boding well for those investing in the EV market.

This dramatic shift in sales mix creates operational challenges for automotive OEMs globally based on factors such as increased model and variant complexity on existing production lines and the need for multiple skills training of operators working on different vehicle assemblies.

These challenges must be overcome without increasing the cost of production. Only the best operational performers will gain the cost and quality advantage over their competitors. This operational advantage can be brought by the disciplined use of digital technologies.

One of the key enablers to solving these challenges is a collaborative manufacturing planning solution. Such a solution helps in creating and managing the engineering and manufacturing bills of material (BOM), developing manufacturing process plans, and providing integrated process simulation and validation capabilities well in advance of production ramp-up. Since most of the work involves multiple, rapid changes across many disciplines, the solution shall help in identifying those changes and making informed decisions based on the complete understanding or their impact.

Siemens’ digital manufacturing software provides automotive manufacturers with a necessary foundation for the transition to EV platforms.

Siemens Digital Industries Software’s manufacturing engineering software solution provides a collaborative platform to make a digital twin of both the manufacturing process and the manufacturing plant (resources) that enable virtual validation of the complete production system and its operation.

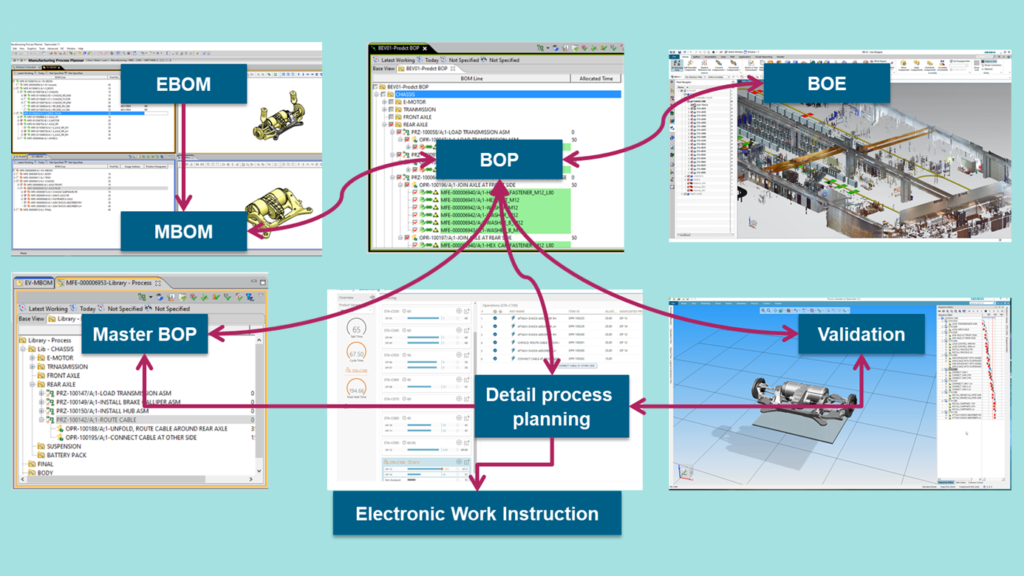

Key to this solution offering is:

- BOM management for improved accuracy of the manufacturing bill of material (MBOM) and its linkage to the bill of process (BOP) and bill of equipment (BOE) to ensure that vehicle production is not held up on the assembly line due to the lack of part or sub-assembly availability

- Validated process plans for faster ramp-up to production volume based on the detailed definition and simulation of the required manufacturing processes, including electronic work instructions, prior to commissioning and production, for identification of new components and their assembly methods and better operator training

- Improved operator utilization through virtual validation of manual operations using line balancing capabilities and ergonomic assessment tools, reducing non-value added work

- Shared data to reduce time for production system updates using a robust PLM system as a digital backbone that allows for the exchange of updated manufacturing BOM, routing and part configuration data with MES (manufacturing execution systems) and ERP (enterprise resource planning) systems on the shop floor

These capabilities and benefits lead to much improved manufacturing data management, process design and validation, and production execution that is critical to building tomorrow’s factories today.

For OEMs who are transitioning to EV platforms and new EV entrants alike, Siemens’ digital manufacturing software solution and the digital twin lays the foundation required for providing the high-quality component assemblies and electric vehicles of tomorrow on time and at the volume necessary to meet the growing global demand.

Learn more about how Siemens can help:

Webinar – EV Manufacturing Challenges Solved

White Paper – Moving EV Manufacturing into the Fast Lane

Blog – Digitalize battery manufacturing for a greener future with electric vehicles

Website – Electric Vehicle Manufacturing

—–

About the writer:

Nilesh Wani is a Principal Consultant in the Manufacturing Engineering Software business segment at Siemens Digital Industries Software. He has many years of experience in the sales, deployment and support of digital manufacturing solutions across multiple industries, with a primary focus on automotive OEMs and suppliers.