Top 8 things I learned from mechanical engineers

In celebration of engineer’s week, I thought it would be nice to send a thank you to all mechanical engineers – the unsung heroes. We are surrounded by products that you design: the smartphones that we use for listening to music, watching videos, catching up with social media… anything but actually making phone calls; the planes that transport us to exotic destinations; the cars we drive today and the ones that one day will drive us; and the devices that keep us alive when our bodies are unable to do it on their own … the list goes on.

Having worked with engineers for most of my career, I am proud to say that I’ve learned a lot from you. Here are the the top 8 things I have learned:

8. Anything and everything is fascinating.

I drive a convertible car. The first day I pulled into the parking lot with the car top down, one of the engineers observed the roof closing at the touch of a button and we spent a few minutes talking about all the systems driving the mechanism. Quite frankly, I had never paid much attention to it – you tend not to until they stop working properly.

Now, thanks to engineers I don’t take things for granted. I know engineers have already designed for most eventualities. Here’s a short video on how the engineers at Mercury Racing designed a new intercooler for a high performance engine and what they had to consider during the design process. If you haven’t seen it yet, it’s well worth it.

7. Choose words carefully.

You are precise with your language. Within weeks of joining the company, I realized that I needed to pick my words carefully in order to communicate effectively with you.

Case in point. I was working on a presentation in preparation for a press event. One slide kept getting flagged as wrong by the team. So I started probing and realized that the problem was with just one word. One single solitary word. We changed the word from “cause” to “contribute” and the slide passed the next round of review. After the engineers left the room, someone complained that the team was being pedantic but I knew they weren’t being difficult. They were simply being accurate. And as we all know accuracy is essential for successful delivery of technical products.

6. They give straight answers.

In sales the golden rule is to never say no. If someone asks you about some functionality which your software doesn’t support, you keep asking questions to find out whether that feature is needed or whether it is a “nice to have”. Engineers on the other hand don’t have any problems with saying no. That’s probably why engineers feel comfortable working with other engineers – they know they’re getting a straight answer. Can’t blame them.

5. There is always room for improvement.

By nature you like to tinker with things because there is always room for improvement. Unfortunately this also means that things may take a bit longer than you expect. Sometimes I feel like a 5-year old kid who keeps repeating “are we there yet?” when working on a project or presentation. But I have learned to be patient because invariably the end result is better.

4. Functional doesn’t necessarily mean the same thing to you.

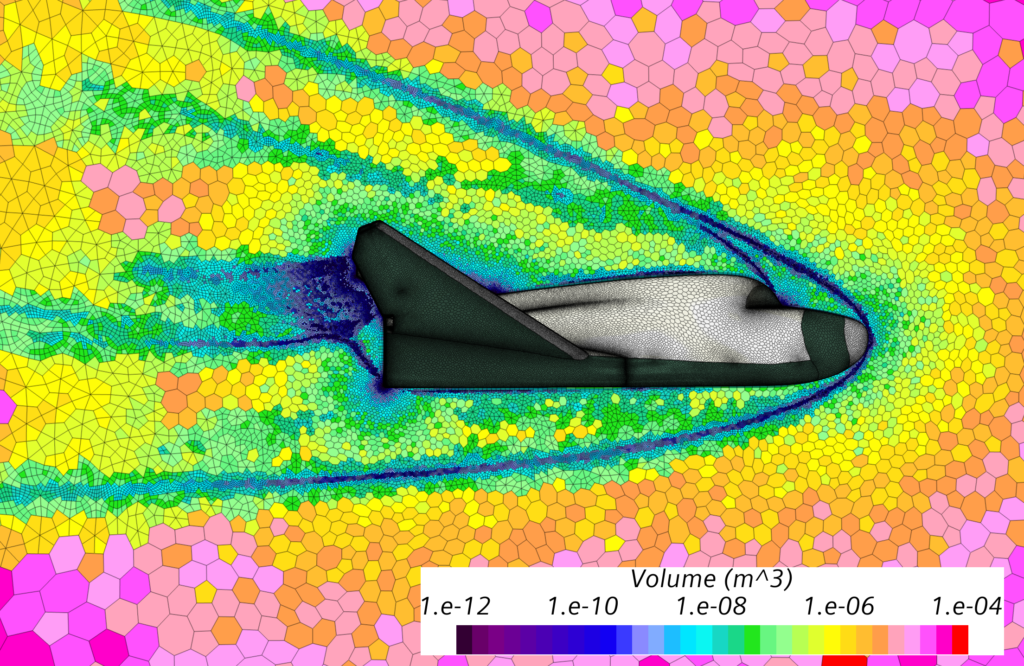

Engineers don’t tend to hold much value for “smoke and mirrors”. When you look at simulation results, you are perfectly happy looking at the basic plots and charts. I on the other hand need to communicate with managers who may not necessarily be engineers. So eye-catching pictures and animations that communicate concepts to both engineers and non-technical decision makers are extremely important. Some of the graphics that you get from Simcenter simulation software solutions are works of art. I mean look at this beauty! And that in my book isn’t eye candy… it’s brain candy! And in case you want to read what it’s all about, please take a look here.

3. Engineers are really nice.

By nature most engineers tend to be introverts so as an extrovert it would be really easy for me to just walk away. But when you take the time to get to know them, then you’ll find that engineers are the nicest bunch of people. Most even have a wonderful sense of humor.

2. Physical testing is just as important.

In the simulation world, we often tend to think of testing as something you do during the final verification phase. But physical testing can offer you so much more. Watch how MacDermid Alpha uses Simcenter testing technology to assess sintered die attach thermal reliability for power electronics. I found it fascinating that using testing equipment helped them communicate more effectively with their customers.

1. Simulation is meaningful.

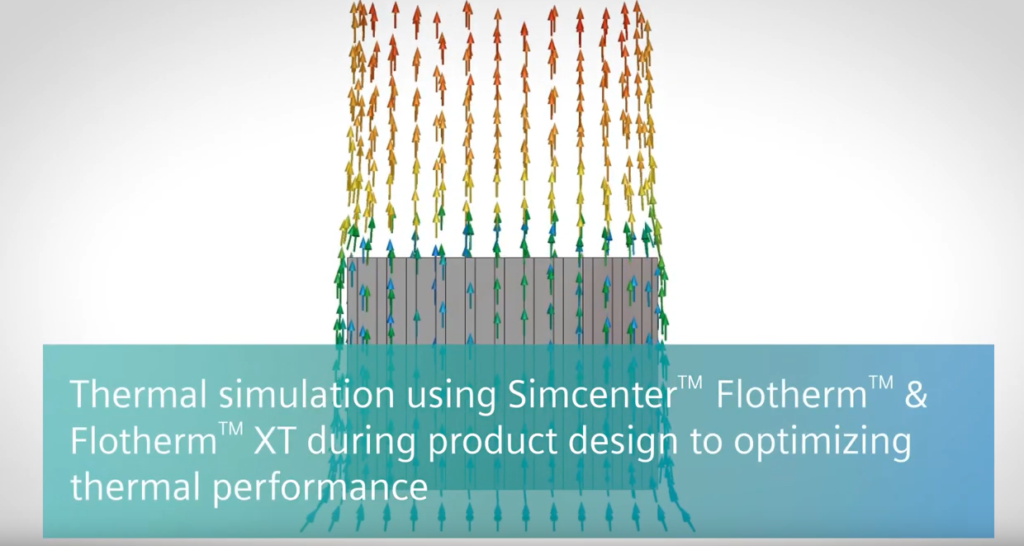

Some folks refer to CFD as color for directors and that simulation is hocus pocus. I am a believer. Especially when I hear it straight from engineers. Take a look at this video by Continental Automotive where they rely on simulation to make sure their products meet the requirements of their customers.

Or how Corrdesa tackles corrosion problems with the help of simulation quickly and effectively.

So thank you, engineers! You have made this a better world for the rest of us.