Praga racing cars: Full speed towards top interior sound quality

Have you ever found yourself watching Formula 1 race on Sunday afternoon? Trilling, isn’t it. Imagine yourself driving one of these racing cars on average speed of 250 km/h. Or perhaps , do you already have such experience?

Praga cars is one of the speed cars manufacturer in this game. Their full-carbon model called R1, developed in 2013, is the company’s chart topper. These cars excel in two extremes – the lightweight construction (592 kg) and the powerful engine with 210 bhp, designed for extreme operational speed. Consequently, these extremes deteriorate the NVH performance from the acoustic point of view. Obviously, racing cars are so loud (also) inside, so that wearing a helmet has an additional reason. It protects driver’s hearing. In term of continuous product development, Praga cars decided to investigate how to improve the acoustics of the vehicle cabin.

Sound source localization using microphone array: smart and easy

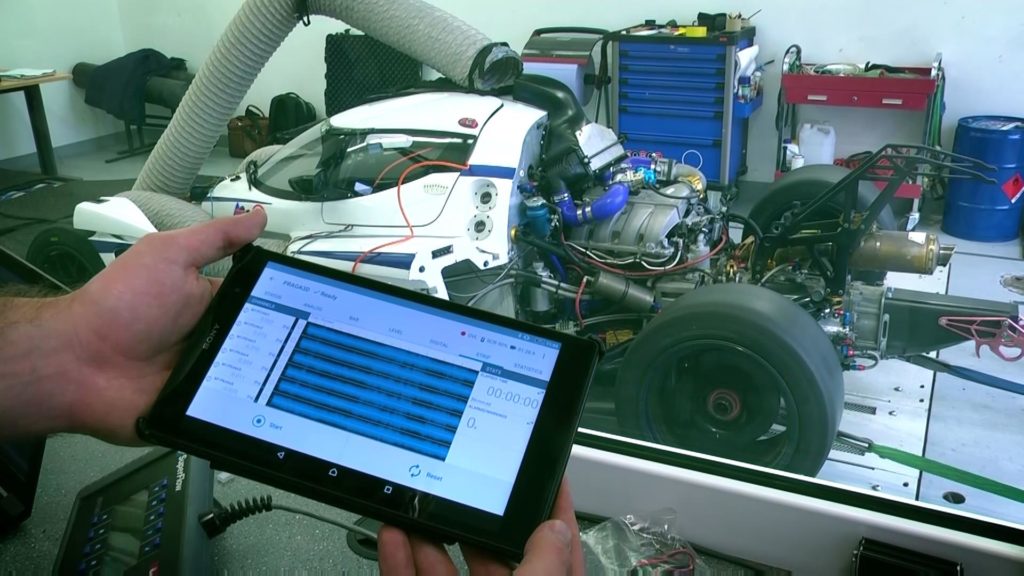

In this case, the Siemens team decided to use the Simcenter Testlab 3D Acoustic Camera solution. This setup is capable not only to localize the sound sources, but also to visualize the sound power contributions. As such, it provides more insights into the noise structures. This solution is a bundle of a 3D Photo Geometry Scanner, Simcenter Solid Sphere Array counting 54 microphones, Simcenter SCADAS data acquisition system (that can be controlled with a tablet app), and Simcenter Testlab 3D Acoustic Camera software.

Investigating the noise leaks step by step

At the first step, the Siemens team installed a frame holding the scanner into the cabin. Once the interior was completely mapped in 3D, the scanner was replaced with the microphone array.

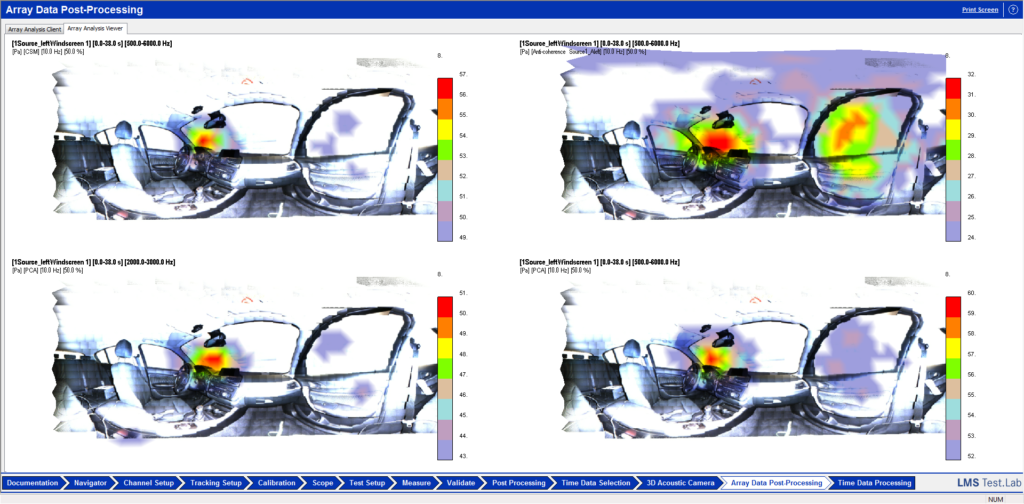

At the second step, the team proceeded with the acoustic measurements. On the chassis dyno, the vehicle ran on different engine rotation speeds, while the camera’s microphones registered the changes of sound pressure in the cabin. As the outcome, the team obtains a clear visualization of the so-called ‘hot spots.’ This visualization accurately displays the acoustic leaks of different exterior sound sources, such as the wheels, chassis, and aero-acoustic noise.

Finally, with this data, the team was able to generate a detailed report. The goal of these measurements is to turn the acquired data into valuable insights for further vehicle improvement. Using the power of this technique, also known as sound source localization, identifies the points of attention straight away. As a result, instead of taking the ‘trial-and-error’ approach, the development teams are now able to tackle acoustic issues strategically.

Getting smart with sound source localization

To sum up, sound source localization techniques have several big advantages: they don’t require extensive time investment, counter measures can be evaluated immediately, and more advanced tools are available for further post-processing.

Are you interested to learn more about sound source localization sing using microphone array technique?

Sign up for this free webinar – Fundamentals of sound source localization and turn this knowledge into your smart engineering practice.