Simcenter system simulation solutions 2019.2: What’s new?

We are proud to introduce the new Simcenter™ system

simulation solutions 2019.2.

With Simcenter™ software system simulation solutions 2019.2, Siemens Digital Industries Software addresses the ever-changing needs of industries for more accurate and competitive system modeling. Simcenter system simulation solutions improve user-friendliness and openness, and the latest application capabilities foster collaboration and enable users to innovate even more to cope with growing engineering complexity.

This new release focuses on three main areas of improvement:

• Mechatronic and thermofluid system modeling

• User experience

• Openness

Discover the main new capabilities in 3 minutes

Let’s have a look at the main new improvements

Mechatronic and thermofluid system modeling

• Electrical systems: detailed thermal e-motor model

• Automotive: new driver for extreme driving conditions

• Automotive: scalable parameter setting for chassis models

• Aerospace: fuel system enhancements

• Off-highway: digging force resistance

• Fluid systems: simulation-based characterization, computational fluid dynamics (CFD) based orifice parametrization

• Fluid systems: computer-aided design (CAD) based gerotor pump characterization

• Fluid systems: dynamic attitude and accelerations

These new solutions drive innovation using mechatronic and thermofluid system modeling.

Among the many enhancements related to the electrification challenge, you can improve performance assessment of e-machines by including its thermal behavior in a more realistic environment. You have access to a detailed thermal model of the machine representing the different sectors that can be integrated into a complete electric drivetrain. This allows you to more accurately assess both the electromechanical performance and thermal behavior during driving cycles.

For the automotive industry, new driver and manual gear shifting applications are available for Simcenter Amesim™ software (automatic drivers released with 2019.1 version). It allows you to solve the most complex cases, such as the real driving emission (RDE) cycle, hill starts, steep slopes and driver style. Further, to simplify the use for first-time users, the parameter settings for chassis models are now scalable. You can access a new chassis component with limited key parameters exposed. It provides first level assumption (left-right symmetry) and parameters (simplified kinematics) for beginners.

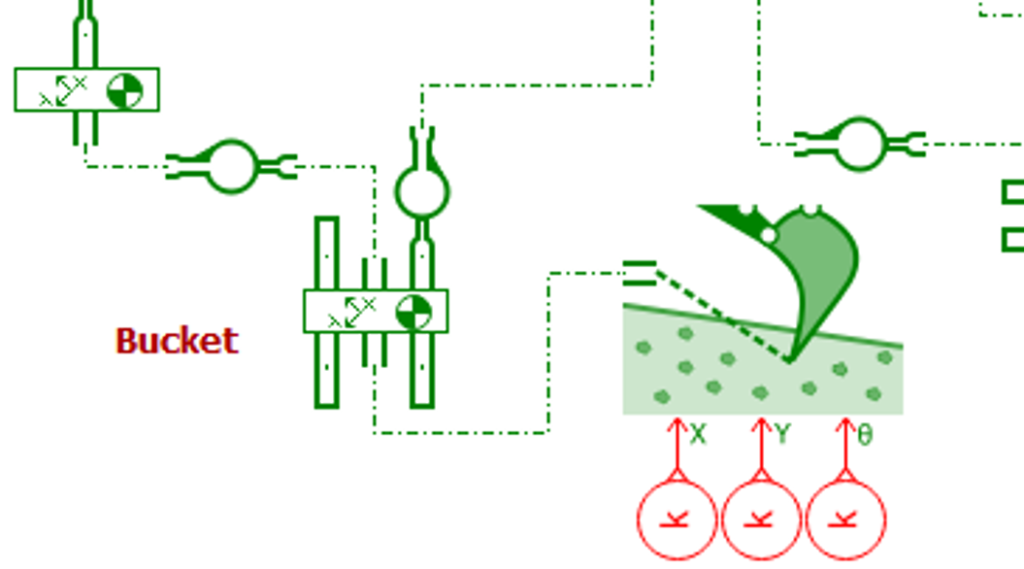

For off-highway applications, you can evaluate digging force and soil resistance during construction machinery operations and then predict fuel consumption. More details in this blog article.

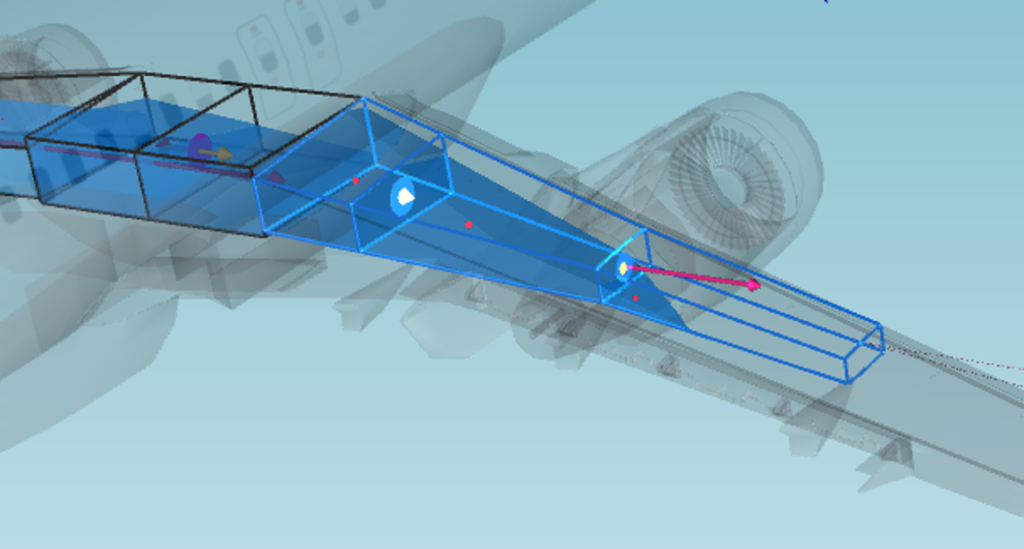

For the aerospace and defense industry, to improve modeling process efficiency for aircraft fuel systems, new features are available such as the advanced fuel system visualization assistant, improved CAD import user experience and unit preference management.

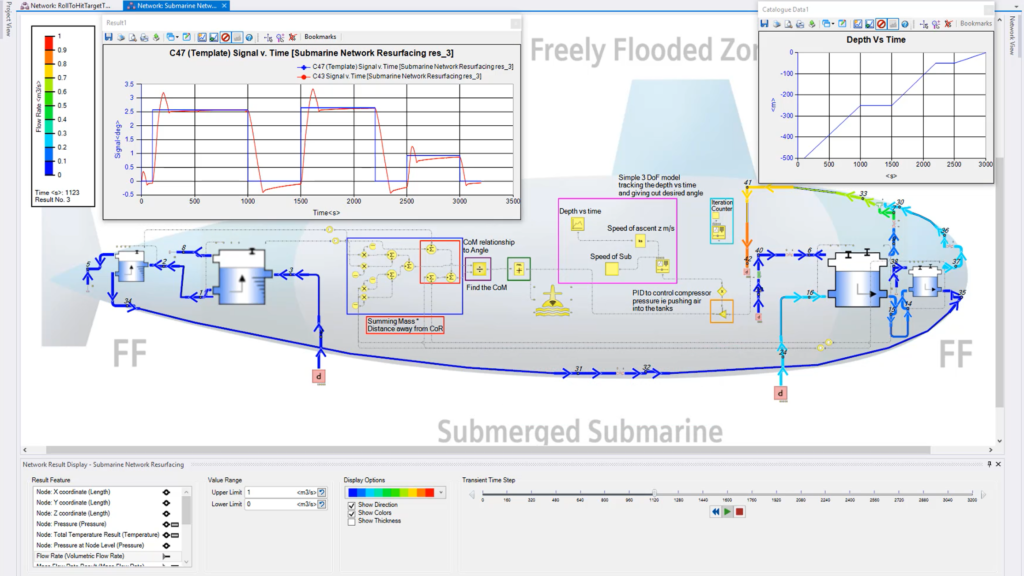

With the new Simcenter Flomaster™ software version it is possible to model the dynamic attitudes of fluid systems, such as acceleration caused by the maneuvers of an aircraft or by a submarine emerging and submerging. The full fluid inertia is modeled in pipes while the transient maneuvers are defined with environmental model components.

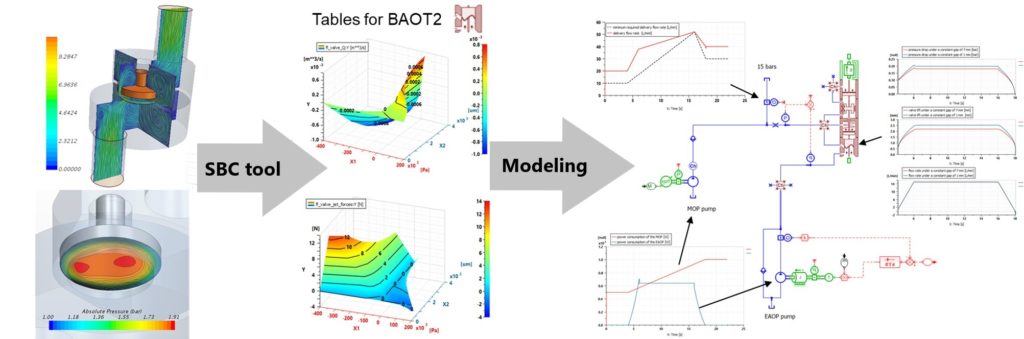

In case of nonconventional geometry, the unique Simcenter Amesim hydraulic component design (HCD) capability is enriched by the capacity to automate the extraction of flow characteristics and flow forces from Simcenter STAR-CCM+™ software. For more details, read this article.

In addition, with Simcenter Amesim, you can quickly build a gerotor pump model for any kind of gear profile and automate the generation of the model’s parameter from the CAD drawing.

In Simcenter Flomaster, the new pump curve wizard makes it easier to characterize a pump from typically available data. The new wizard is easily accessible from the launchpad, components and curve data entry.

User experience

• Neural network based reduced order model (ROM)

• Graphical interface responsiveness improvement

• Python 3 and Visual 2015-2019 support

• Visual physics

A second set of features, the improved user experience, allows you to boost collaboration and efficiency throughout your company.

The integration of a neural network builder in Simcenter Amesim allows you to create a neural network representing static and dynamic systems. Without prior knowledge, users are now able to easily simplify complex dynamic systems into compact, real-time neural networks and re-use them in Simcenter Amesim models.

Simcenter Amesim 2019.2 has much improved graphical interface responsiveness. The user interface supports more scalability and helps you achieve reduced turnaround time for all your models.

Simcenter Amesim now complies with versions 2015 to 2019 of the Microsoft Visual C++ compiler. You can also take advantage of the latest Python 3 language features and automatically migrate your Python 2 Apps.

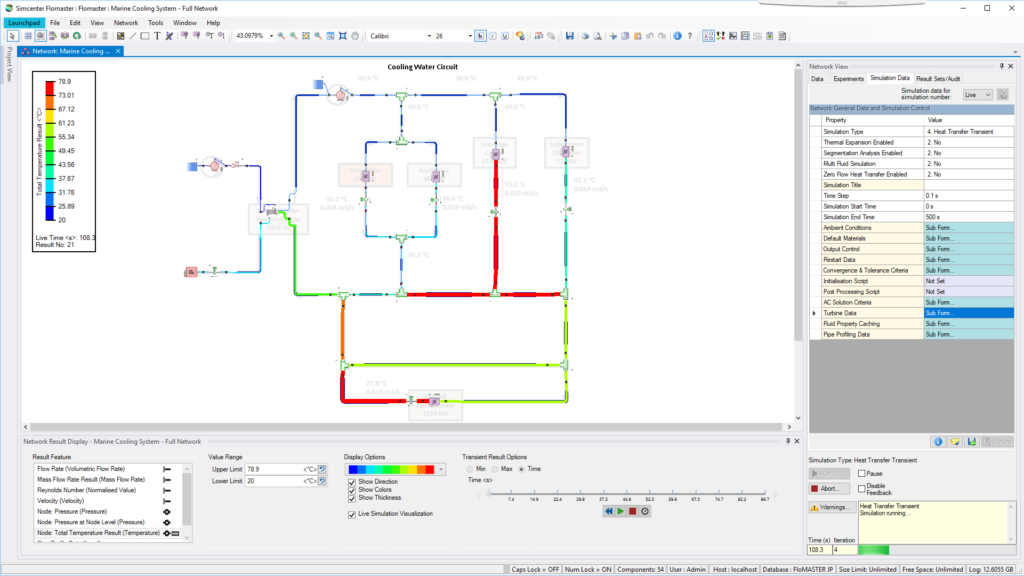

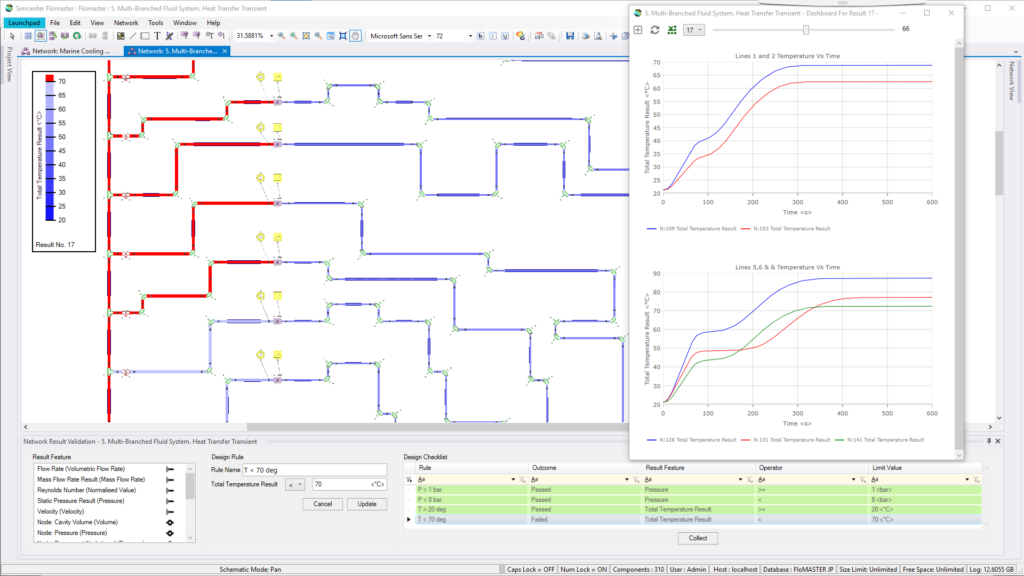

Quickly understanding the physical behavior of thermofluid systems is a priority for Simcenter Flomaster users. From this release on, physical results can be visualized on the model schematic either during the simulation or as playback. Also, users can specify requirements and constraints and immediately check if they are met. This allows users to immediately spot problematic areas of a large fluid system.

Openness

• High-performance computing (HPC) monitoring and extended scheduler support

• Simcenter Webapp Server backend application programing interface (API)

• Extended Functional Mock-up Unit (FMU) support

We’ve also improved the software’s openness. From now on, it is easy to submit a Simcenter Amesim model to HPC for non-experts through a dedicated graphical user interface (GUI). To this end, scripts or command lines are not mandatory anymore and you can easily monitor simulation status and access results from the GUI. Read this knowledge base article to learn more about this feature.

This new release comes with a Simcenter Webapp Server API. With this, for example, a user can create his or her own Simcenter Amesim Python app to upload a model on the Simcenter Webapp Server directly from Simcenter Amesim. More details on this blog article.

From this version on, Simcenter Amesim models containing Modelica or Simulink components can be exported as FMUs on standard platforms (Windows or Linux) while transparently handling Modelica and Simulink internal resources.

FMU 2.0 for model exchange can now be imported into Simcenter Flomaster 2019.2 to extend simulation limits and enhance collaboration. A response surface model-based FMU 2.0 for both model exchange and co-simulation can be created, which enables it to be flexibly re-used at maximum speed.

Want to know more?

Those are only a few of the major capabilities introduced to Simcenter system simulation solutions 2019.2.

– Don’t miss our blog posts and how-to articles

– Contact your local Siemens Digital Industries Software office

Comments

Comments are closed.