Simcenter SPH Flow and Studio 2.3 released! What’s new?

With booming electrification and the autonomous driving trend, vehicles are equipped with more and more electronics ranging from onboard computers to electric batteries, sensors, and radars.

The resulting disruptive architectures, with the underbody containing valuable components and sensors, that are the eyes and ears of the vehicle pose numerous challenges to automotive manufacturers. Designing and implementing sensors that function under even the most challenging driving conditions, therefore, requires reliable simulation methods.

With this mission in mind, Simcenter SPH Flow & Simcenter SPH Flow Studio 2.3 delivers new extended physical models and improved user experience to help designers and CFD analysts design better performing products with a reduced time-to-market.

To download Simcenter SPH Flow and Simcenter SPH Flow Studio 2.3, please visit the Support Center

Accurate solid-solid contacts with the new collision model

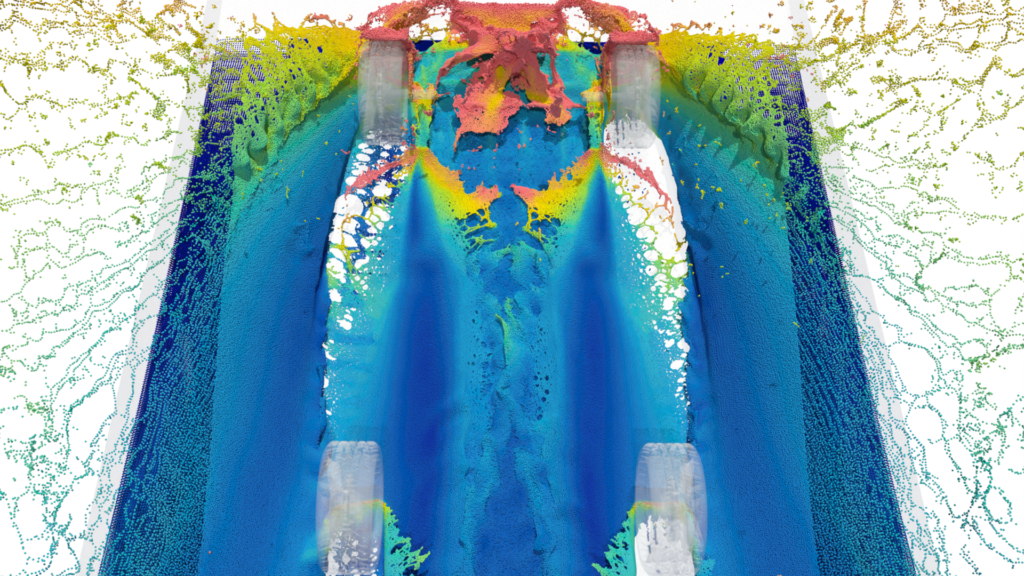

Vehicle fording requires accurate prediction for the representation of the vehicle motion from the contact in-between the tires and the road. The new collision model in Simcenter SPH Flow 2.3 allows getting high-fidelity automotive wading simulations.

This model can also be applied for other applications with contact in between solid bodies such as lubrication simulations with iron filings in the powertrain industry and mixing simulations in the food processing or pharmaceutical industry.

High-fidelity hydroplaning predictions with extended FSI co-simulation

High-speed fording generates high-pressure splashes on the underneath structure of the vehicle. Tire deformation has an impact on wet adhesion performances during hydroplaning.

These applications require efficient coupling between the fluid and the structure to get high-fidelity predictive simulations. The extended capabilities of fluid-structure interaction (FSI) co-simulation in Simcenter SPH Flow 2.3 allow you to predict the constraints on the underneath part of the vehicle and to represent the complex hydroplaning phenomena. You can now ensure optimal safety and sustainability performances of your vehicle.

Increased productivity with enhanced user experience

The setup of a complex simulation usually requires a lot of manual operation and therefore, a considerable amount of engineering time. With Simcenter SPH Flow Studio 2.3, several new functionalities enrich your user experience and increase your productivity. Your entire workflow can now be automated with Python scripting capabilities. You can also benefit from enhanced interactive tools for the definition of kinematic axes and position of geometries and from further improvements in the management of clipping plane representation.