Perovskite solar cells: mitigating the cracks in the energy crisis

Perovskite solar cells have the potential to significantly reduce the cost of solar cells. However, before their mass production with low-cost printing methods, devices require flexibility. In this blog, we look at why solar panels need to bend, the benefits of flexibility, and the science behind achieving this.

“I hope to create a world where solar panels are as readily available as batteries”

Melissa Davis

Forbes states that the average cost of solar panels is $16,000, and installing the panels will cost you a further $15,000 to $25,000. As a result, the high initial investment is the primary reason that most households do not generate their own electricity. The most widely available solar panel on the market uses large silicon crystals. These devices require an expensive, energy-intensive, multistep manufacturing process. Due to this expense, scientists are investigating alternatives such as the perovskite material. An additional benefit of making perovskite solar cells is their mechanical resilience with bending. Flexibility allows for a significant reduction of installation costs.

Imagine a future with perovskite solar cells

Melissa imagines a future where your cell phone can be charged at the beach using your towel as a solar panel. In such a future, sailors could use their sails as both a wind and a solar energy capturing device, so in light winds, they can continue to make headway without turning on a diesel engine. This is no flight of fancy, at The Washington Clean Energy Testbeds, scientists can already use roll-to-roll printers to print perovskite inks onto flexible materials.

“Perovskites solar cells are the future solution to the energy crisis. There is a lot of solar energy available that we are not using because of cost barriers, and I want to change this”

Melissa Davis

What are perovskite solar cells

The word perovskite describes a specific crystalline structure. Perovskites can be found in nature as calcium titanate and were first discovered in the Ural Mountains in 1839. The structure can be replicated with various other elements; however, a subset of perovskites called metal halide perovskites have shown promise due to their superb optical and electrical characteristics. Their semiconducting properties make them a suitable material for solar cells.

What is special about perovskite solar cells

Despite being an emerging technology, perovskite crystals are already demonstrating efficiencies that rival silicon solar cells. Metal halide perovskites have the additional advantage of a significantly lower manufacturing cost than silicon. A further cost reduction is possible with roll-to-roll printing, similar to a newspaper printing assembly line. The roll-to-roll technique prints each sequential layer quickly to form the complete device with a high production rate.

Melissa Davis

Ph.D. candidate Melissa Davis reads Industrial Engineering at the FAMU-FSU College of Engineering. Melissa found a problem she wanted to solve and secured funding from the NSF Graduate Research Fellowship Program and is also supported by her advisor, Dr. Yu. The support has allowed her to focus on a subject she believes could make a genuine difference to the world. She conducts her research at the High-Performance Materials Institute (HPMI) under the direction of Dr. Zhibin Yu and collaborates with Dr. Rebekah Sweat. Melissa hopes her research will show the promise of novel material perovskite solar cells for commercial applications

What is the problem

While roll-to-roll printing will decrease cost, it requires flexibility in the perovskite solar cell. The solar cells must tolerate mechanical stress during manufacturing as it is bent around drums. However, research in the mechanical properties and structural performance predictions of perovskite solar cells is in its infancy. In addition, investigating mechanical degradation behaviors requires specialized testing equipment, which is costly and time-intensive.

A substantial challenge for solar cells is resisting cracking. Cracking decreases efficiency and reduces the lifecycle of the product. The risk of cracks can increase delivery and installation costs, thus increasing the risk of a solar project which creates an additional barrier to their adoption by the masses. The ability to reduce cracking and increase flexibility for perovskite materials would significantly affect the impact of this renewable energy technology. Figure 1 demonstrates what we would require from a flexible solar cell.

“In one hour, the amount of the sun’s energy that hits the earth is enough to power the entire human populations’ needs for a full year”

Melissa Davis

Melissa’s quest

Melissa had seen the same problem that many researchers had come before her, but she approached it differently. Commonly, researchers create perovskite solar cells then physically test their electrical and mechanical properties. While effective, this is a lengthy and costly process. Furthermore, nothing is known about a crystal until after the test, so development relies on the scientists’ experience to make the best guess. The issue regarding the disconnect between engineers that commonly use simulations and materials science that do not, has previously been discussed in this webinar. Melissa’s idea was to create a digital twin computer model to predict the test’s outcome. In this way, she could simulate perovskites before she manufactures them. With this method, you only need to produce and test the most promising examples, significantly reducing the time and cost required to find the perovskites solar cells desired.

How is Melissa approaching the problem?

To build her digital twin, Melissa has been using Simcenter Multimech software. This tool allows her to create and refine a digital twin model of perovskite solar cells undergoing mechanical degradation. Since efficiencies of perovskite solar cells decrease when mechanically damaged and cracked, a better understanding of the cracking behaviors of perovskite films is paramount. This software allows her to study further causes of breaking and acknowledge then address the mechanical weaknesses.

Trailblazer

Melissa’s computer model enables her to predict solar cells’ cracking behavior, which is an entirely new concept in the field. This modeling approach makes her a trailblazer in the science of simulation and modeling of perovskite solar cells.

Modeling the complexity of perovskite solar cells

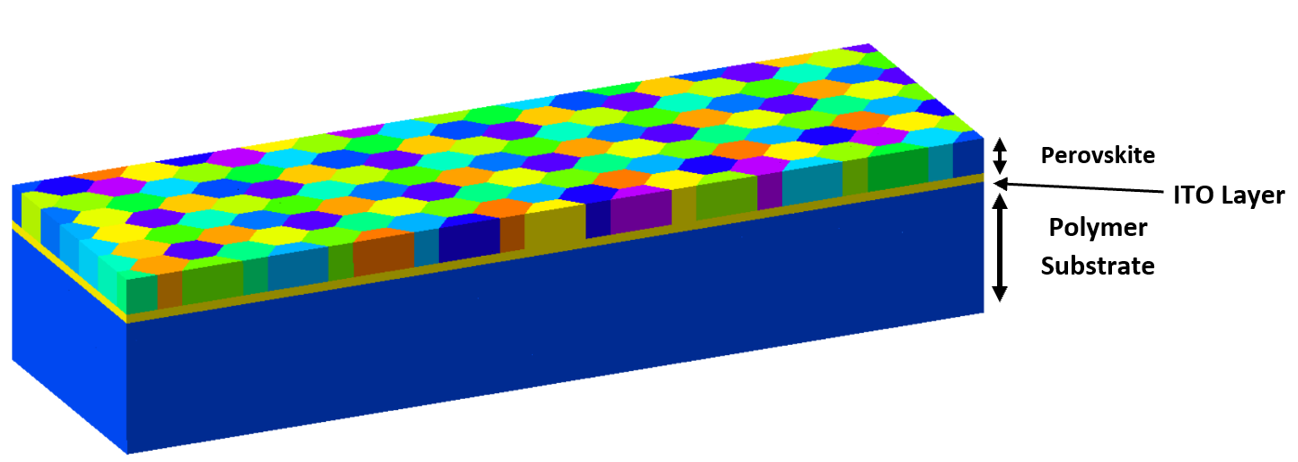

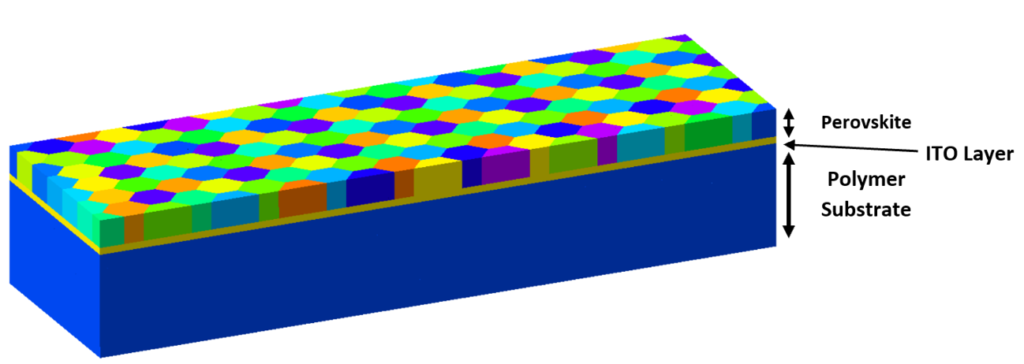

Automatic cracking in simulation allows for competing and progressive damage to be studied. Optimal parameters can be discovered as well from material selection, manufacturing thickness, and mechanical bending performance. The testing coupon can be seen in Figure 2. The top hexagonal units represent the perovskite crystal geometry. Cracking is allowed between crystals, within each layer, and at the interfaces of materials.

Explore the possibilities

While ITO demonstrates excellent electrical properties, research has shown it is often a mechanical weak spot. Therefore, researchers can search for a suitable replacement by better understanding its role in mechanical degradation. Such a replacement will ensure roll-to-roll manufacturing is a viable option for commercialization in the future. Utilizing a digital twin of the solar cell enables a ‘materials-by-design’ approach, where Melissa can virtually test many material candidates to assess promising next-generation materials for their implementation in solar cells.

A mechanical weak point of perovskite solar cells is the Indium Tin Oxide (ITO) layer. While ITO demonstrates excellent electrical properties, research has shown it is brittle. The cracks that traverse the top layer of crystals can be seen in a ‘zig-zag’ pattern, following the crystal boundaries. Simulation shows that perovskite cracking is driven by the brittle nature of the ITO, which matches expectations. ITO replacements can be studied to compare crack resistance with the same loading conditions, with a reasonable model in place. Figure 4 shows an ITO replacement material in the middle layer with significantly higher bending without crack development. Stresses are seen to accumulate at the top surface but resist the formation of a crack better than the traditionally used ITO.

More on the work of this team

if you would like to find out more about the work and experiences of the female researchers featured in this article follow this link to an article we produced for International womens’ day.

Find out more about material modeling in the following blogs

Multiscale Analysis: A General Overview and Its Applications in Material Design

Crack propagation in composites and how to avoid it: A DLR case study