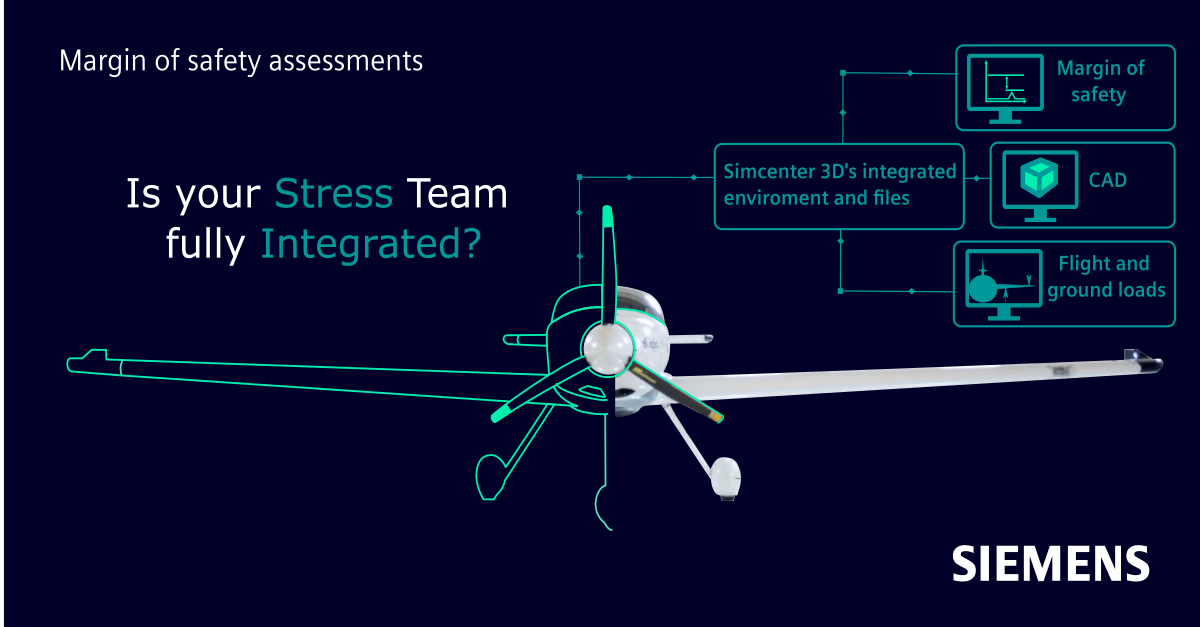

Simcenter 3D Margin of Safety Assessments: Search, seek and deploy

“I’ve never known an industry that can get into people’s blood the way aviation does.”- Robert Six

Margin of Safety – Introduction

Margin of Safety is an integral part of the work performed by many stress teams. The recent updates to Simcenter 3D have attempted to unite engineering teams and improve collaborative processes. To get a better understanding of how this is affecting the users we regularly reach out to them for feedback. The following highlights some of the responses that we have had.

The experience of a Stress Engineer

Prior to recent updates, I had a conversation with a Stress lead, where I posed a hypothetical question: “if you were to picture yourself as an airplane that is experiencing all the loads exerted on it during flight, what do you imagine?”

“I envision a huge force across my chest or wingbox with both wings strongly pulling outward, tearing me apart!”

Perhaps a slightly darker response than I had anticipated. I pushed on sensing that he had more to share, maybe it was a problem I could solve. I had known him for some time and had sensed he was under some stress.

“Now could this be an analogy for the way your company works?”, I asked.

The complexity of large organizations

“Yes!” I pulsed and waited for him to go on “Since I am an engineer working in a method & tools (M&T) department, I must cope with the constraints of the program I am working on. Often this is, stress engineers working on the latest lightweight materials, who are always requesting the latest revisions to testing methods from my team.

Not only do I have to complete my engineering tasks, I am also in charge of spreading the knowledge I have gained from tests and simulations in a timely manner to other teams. Since it is my job to ensure the whole community has access to the latest version of my results at the same time. It is a laborious process that takes time.

Pulled from all directions

Additionally, it also takes stress engineers time to crosscheck all the parameters of their methods with mine to ensure consistency before continuing their tasks. As a result, the more effort I put into the documents I share, the less work others have to do. Any additional time I give can result in significant time savings for the wider team. Why this seems obvious to me, and the other teams are always grateful for the work I put in, management doesn’t seem to understand and is always asking me to do more. Going back to your wing analogy, this time-consuming process of sharing results is the load pulling the deployment task on one wing to one side.”

I am not an expert therapist but since he had only mentioned one wing and I figured there was more. “What about the other side?” I asked.

Meeting the I.T. security requirements

“Pulling from the other side is I.T. with ever-evolving security rules to secure the network and the data that flows through it, they have a lot to deal with. They need a clear, well-defined, stable-in-time way for me to provide all necessary tools to the engineering community. Any new (or even altered) way to do so would require possibly weeks to get clearance, to eventually be deployed.”

This engineer’s problems are not unique to him. A wing box requires a lot of strength to overcome the opposing forces acting upon it, particularly when passing through rough air. The same is true for an engineer who has to deal with their own kind of turbulence, such as unexpected changes in the design, that introduces a method update at a critical moment in the process, or I.T. having a major security update throughout the whole company. These are just two, but the list of possibilities can often feel endless.

Stuck in the middle

You can strengthen your process as much as you want, but in the best-case scenario, you will over-constrain both sides, resulting in both your supplier and customer being unsatisfied with your work and frustrated with collaborating with you, despite the hard work you have put in.

In the worst-case scenario, you, in the middle trying to tie firmly together two opposite constraints, will just break!

So, is it a lost cause?

If you are an engineer worth your salt, you can solve almost any problem, but it does sometimes help to stand on the shoulders of giants, or in cases like this Lead Engineer it would be nice to have some tools that can support you and lessen the workload. Tools and in particular software tools can come with a catch. The more heterogeneous the software set, the less flexible the deployment. You may need to adapt the deployment process to cater for every parameter, method, and workflow used in our organization’s software set so that there is consistency throughout the company. But this can be beyond the M&T team’s bandwidth.

The solution

To overcome these problems Siemens have developed a solution. Siemens Xcelerator software caters to numerous industries, workflows, and physics problems that are all designed to work in an integrated portfolio. This means that across an organization files can be shared, and workflows can be optimized. As a result, Simcenter 3D has been developed with connectivity as a key goal. Thanks to this goal, with Simcenter 3D Margin of Safety it’s possible to dramatically increase the flexibility of intra and inter-team workflows. Having a single all-in-one software dramatically reduces the burden to ensure consistency across your entire workflow: it comes out-of-the-box!

A few months later

Knowing what a difference Simcenter could make to my friend, I introduce him to it. A few months after the installment I revisited him to see how it was going.

He was now wearing a smile and he said emphatically “All you have to do, is ensure that Margin assessment methods are all located in a single folder that is shared or replicated by the user [depending on IT ruleset]. The assessment methods are taken into account like a “plugin” that works like magic, updating an existing method or adding a new one! As a result, we deploy the minimum number of files in a well-organized structure.”

Being agile

He went on, ”better yet! it is designed to work with all your FEM and SIM template files. As such, it provides a harmonized and fully integrated simulation/assessment platform, which has been key to us adopting an agile engineering process.” A change I know he had long advocated to improve efficiency but also for the tracking tools that are available, so he can easily show management just how much work his team has been doing in simple graphs even the least technical manager could understand.

Easing deployment

My last question for him was, “how has it affected your most common tasks?”

“One of the direct benefits is that it significantly eases the deployment and the updates throughout the whole stress engineering community.

Simple and reproducible steps in the deployment process require far less cross-checking overhead while ensuring a very robust set-up, whatever your IT constraints.”

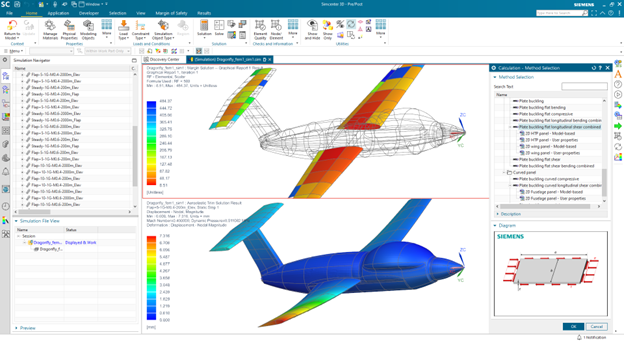

I can’t wait for him to try the new Simcenter 3D 2212 release, it’s now as easy to deploy calculation templates as FEM and SIM templates! These calculation templates are the key to streamlining the usage of the same method on a variety of finite element modeling flavors. As they can now be deployed following the same process as methods, our users can now get standard methods applied to their own “flavored” model, without any effort: it comes directly into the method selection tree (figure 1)! No additional training is needed and this works directly with the harmonized user experience that has already been reducing ramp-up time for newcomers.

In Summary

All in all, it’s far less work to make or update the methods (as they can be reused on any model) and to still deploy efficiently more tailored features than before; and of course, have the updates adopted quickly by the stress engineers!

It was clear that my friend was much happier now so I tried to make him reflect on what had changed. “So now, when you look at an aircraft from the front, what do you imagine?”, I asked before leaving.

“I’m still this wing box, but now, thanks to Simcenter 3D Margin of Safety, I don’t feel like I am breaking under the pressure, and I have confidence I can satisfy both IT and the stress engineers’ requirements! I feel I can be much more flexible now and this Flexibility is key to me achieving new efficiency goals.”