Prometheus unleashed: mastering machine learning in turbomachinery design

Machine learning in turbomachinery design and the mythical figure of Prometheus takes centre stage in this blog. It’s interesting how, without consciously intending it, a consistent pattern has emerged in my blog writing: a natural inclination to weave in references to ancient myths and stories.

These timeless tales have always captivated me, not only for their entertainment value but also for the profound wisdom they hold. In light of the current surge in popularity surrounding machine learning and the transformative possibilities it offers for humanity, my mind couldn’t help but wander to the mythical figure of Prometheus.

Machine learning in turbomachinery design

In the spirit of Prometheus, who bestowed fire upon humanity, igniting innovation, today’s engineers are harnessing machine learning (ML) to transform turbomachinery design in industries like aerospace, energy and industrial machinery. Siemens Digital Industries Software is at the forefront of this revolution, driving advancements with simulation and testing capabilities.

Siemens Digital Industries Software collaborates with technology partners who complement its offerings. One such partner is Advanced Design Technologies (ADT), renowned for its expertise in 3D inverse designs of various turbomachinery components over the years. And in today’s aerospace business there are tougher requirements than ever before, and one must use the latest in simulation technology to meet those requirements. This includes several components in the air as well as on the ground that can be improved. From the propulsion of the jet engine to fans for cooling electrical components and HVAC systems, to fuel and water pumps.

The role of machine learning in turbomachinery design optimization

Machine learning and AI can play a major role in helping to achieve optimal design and increased productivity of turbomachinery applications, especially when it comes to hard-to-solve problems which mainly involve multi-objective, multi-point or multi-disciplinary optimization.

However, the application of machine learning in turbomachinery design optimization, where each data set evaluation is computationally very expensive, is only feasible if accurate machine learning models can be generated with very small data sets. To achieve this objective, three key areas need to be addressed:

- Improvement in machine learning models that enable high accuracy with small data sets.

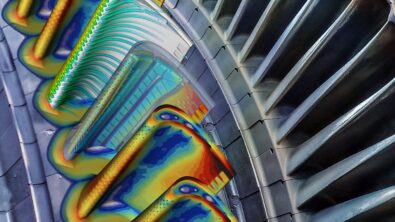

- Improvement in parametrization of the blade geometry, a key long-neglected aspect of achieving high-accuracy small data set models.

- Improvement in automation in evaluating key performance parameters

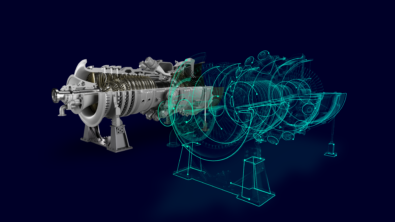

The TURBOdesign Suite and Simcenter STAR-CCM+: a powerful combination towards machine learning in turbomachinery design

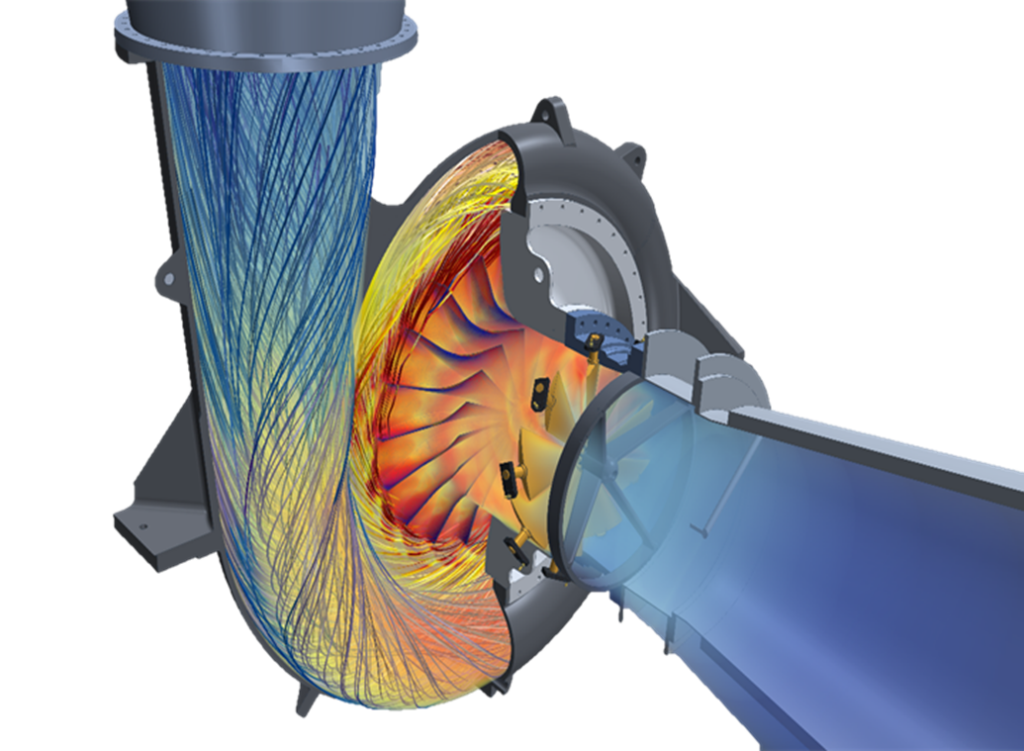

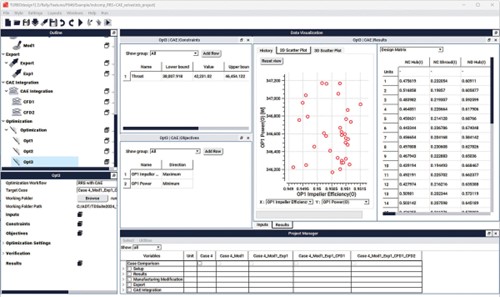

In the ADT TURBOdesign Suite 2024.2 release, all three of the above functionalities were addressed by coupling 3D inverse design parameterization with the unique functionalities of the new Reactive Response Surface (RRS) and automatic CFD integration with Simcenter STAR-CCM+. This enabled an important foundation for the application of machine learning in turbomachinery design, which allows for precise models using smaller datasets, crucial in computationally intensive sectors.

The TURBOdesign Suite crafts precise blade geometries, while Simcenter STAR-CCM+ evaluates performance efficiently via computational fluid dynamics. This synergy accelerates the design process, enabling quicker market entry and enhanced operational efficiency. This machine learning-driven approach does more than speed up design; it optimizes performance across varied conditions, reducing energy use and costs—aligning with sustainability goals. Embracing these tools empowers engineers to solve complex optimization challenges, pushing industrial design toward a more innovative and efficient future

If you have a keen interest in exploring the field of machine learning in turbomachinery design, don’t miss out on the webinar highlighted in the section below. Join me and other industry experts from Siemens Digital Industries Software and ADT as we delve into this cutting-edge topic.

ON-DEMAND WEBINAR

Application of Reactive Response Surface Machine Learning System to Multi-Point Optimization of a Centrifugal Pump Impeller

ADT and Siemens Digital Industries Software

Machine learning in turbomachinery design as the modern Prometheus’s flame

As we continue to explore new frontiers in engineering, machine learning in turbomachinery design stands as the modern Prometheus’s flame, illuminating paths to greater efficiency and innovation. The future of industrial engineering is here, propelled by the transformative power of machine learning.

Prometheus, whose name means foresight, was punished by Zeus, the king of the Olympian gods, for eternity due to his actions. He bestowed upon humans a tool meant solely for gods. Whether the decision to unleash AI is beneficial or not remains uncertain, and only time will reveal the answer.