Improving vehicles beyond the showroom: Extending EV battery life through smart management

Do you have an electric car?

Chances are it has a range of at least 200 miles (320km).

Have you thought about how long the battery will last before it needs to be replaced?

Electric vehicles are a vital part of the push towards sustainability and offer drivers significant savings on fuel. But replacing the battery is expensive and if it doesn’t achieve a reasonable lifespan, any emissions savings are negated.

This is why manufacturers are investing heavily in EV battery technology to ensure consumers get the most value from them. But the story doesn’t end once the battery design is finalized and installed in a vehicle. Lifespan is determined not only by the design, but by the way in which the battery is used.

So, what can be done beyond the design and manufacturing process to extend battery life?

Software defined vehicles

Electric vehicles are designed with a certain control logic that safeguards battery life, but this is based on assumptions on how the vehicle will be driven. However, batteries are significantly impacted by environmental conditions, charging habits and driving style. For instance, driving in a hot climate mostly on highways will age the battery in a very different way than driving mostly around cities in a cold region. As well as the environmental temperature and humidity, all kinds of factors have an influence, such as the frequency and type of charging and discharging.

Software-Defined Vehicles (SDV) are a subset of Software-Defined Systems (SDS), a development methodology where software and hardware are flexible and refined in parallel. 5G connectivity enables live updates to vehicle systems to add features and improve performance. This has typically been used for Advanced Driver Assistance Systems (ADAS) updates, but there is a trend to extend it to more systems such as software-based dashboards and component performance as vehicles become more digitalized.

As this trend continues, manufacturers have the opportunity to continue to optimize vehicles after sale, improving performance and extending their lifespan. The battery is a perfect candidate for this. Similar to how some mobile phones have a feature called adaptive charging, which understands your typical usage and changes the charging to preserve battery life, the same can be done for vehicles. This could be sold as an add-on subscription that drivers can purchase to analyze and adapt the configuration as the system learns more about how the vehicle is being used.

EV battery management over the air

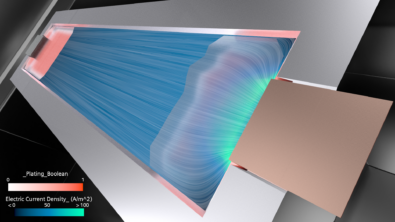

Simcenter Engineering Services has designed a solution that analyzes driver habits and adapts the EV battery management system (BMS) accordingly over the air (OTA) via a wireless connection. This includes charging, discharging, cell balancing, and thermal management which ensures safe and efficient operation and extends battery life.

The great thing is, one of the key components of the solution already exists.

Digital twins are commonly used in vehicle development to optimize designs before prototyping. Now these virtual models can continue to deliver value throughout the life of vehicles.

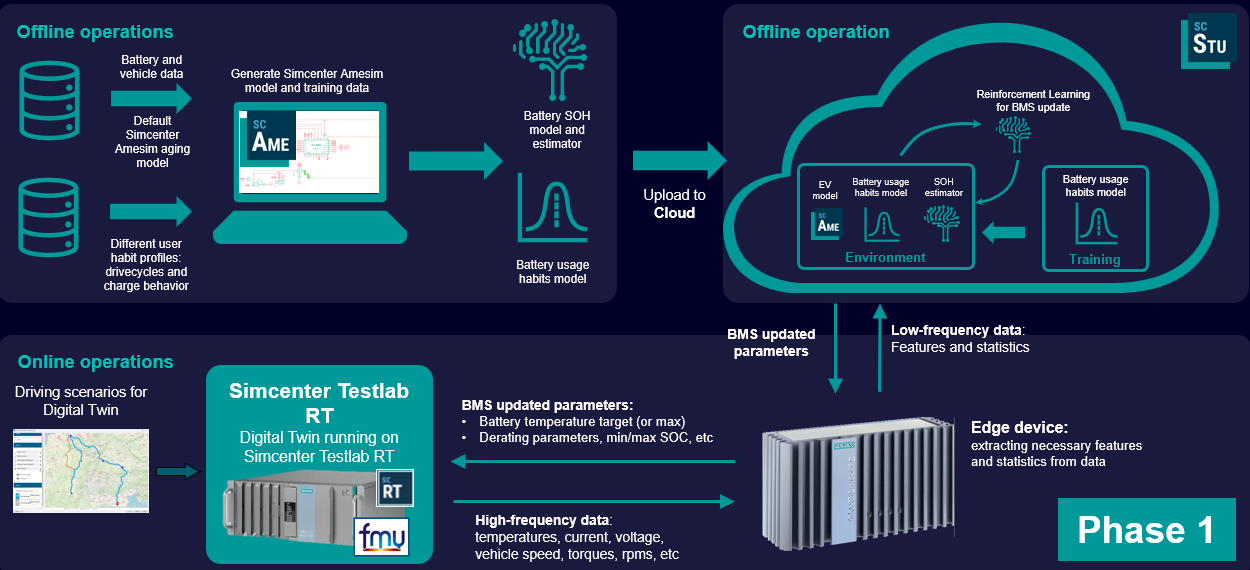

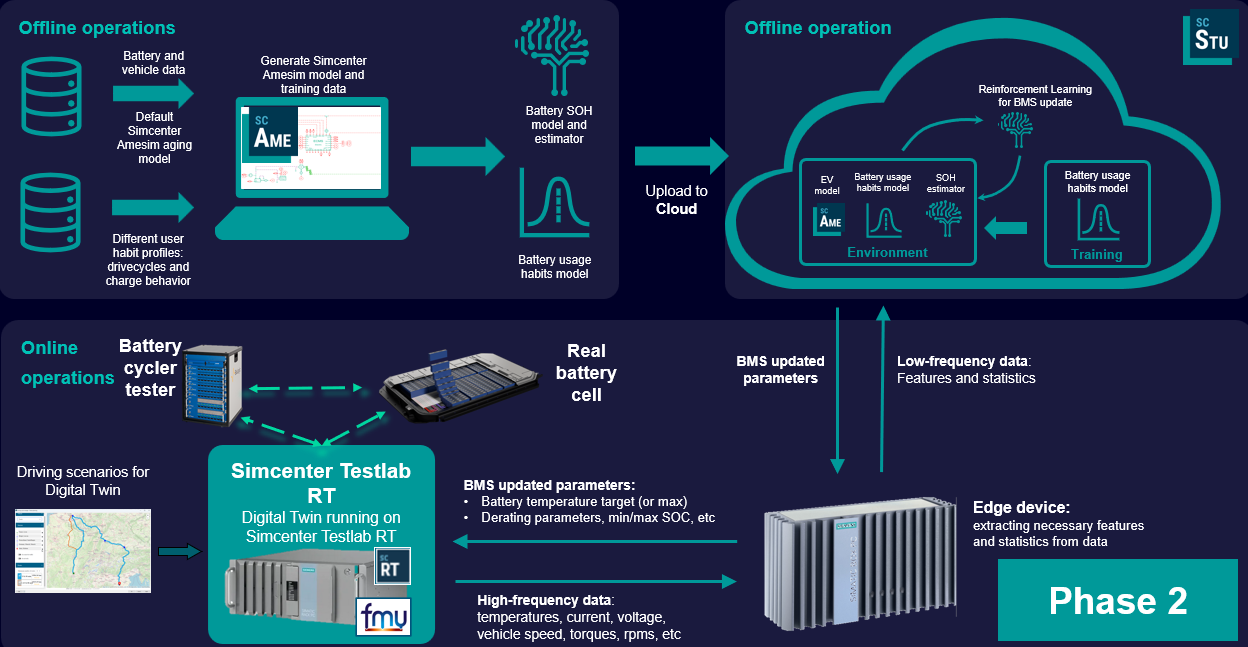

Vehicles are fitted with an edge device that processes data and extracts key information on the battery, such as how often it is charged, at what level it is normally charged, and what type of charging station is used. This information is then sent to the cloud-based application, Simcenter Studio, which features a reinforcement learning (RL) agent that uses the data to derive a customer profile and predict the future usage of the vehicle.

It uses the model as a training environment and learns by getting rewards or penalties depending on how the control modifications affect the battery. Finally, it calculates an estimate of how much the battery life could be extended by, then sends this to the driver to give them the option to apply the new settings to the BMS.

To demonstrate the effectiveness of this proposed solution before applying it to real vehicles, engineers with Simcenter Engineering Services have simulated the entire process. They used the existing digital twins developed in Simcenter Amesim to simulate different driver profiles over many years and generate all the necessary data to test the performance of the AI agent.

They created a functional mockup unit (FMU) to import into Simcenter Testlab RT. It has all the virtual sensors that a real vehicle would have to measure temperature, current voltages, speed, torque and much more. This allows them to demonstrate how the BMS would be updated for different driver profiles and estimate how much the battery lifespan would be extended by in each case.

Beyond batteries

The first phase of the project is to demonstrate everything virtually, and results from this should be available soon. Next, a physical battery will be added to the virtual model, to validate that the BMS changes are improving the battery life of real hardware.

This use of technology opens up many possibilities for optimizing and improving performance throughout a vehicle’s lifespan. For instance, a similar process could help extend range as well as battery life. Even the simplest ADAS features like cruise control consume energy, so if all this data is recorded and analyzed the BMS can be adapted to set power limits and protect the driving range. Alternatively, digital twins can simulate wear and tear on components such as shock absorbers depending on different driver profiles. Then, just as with the battery management system, adjustments can be made to minimize degradation and extend the life of these components.

The best part? All the necessary technology already exists within Simcenter. It’s just a matter of having the expertise to combine the tools in the right way to suit a particular vehicle or product line. This is where Simcenter Engineering Services experts can help. What manufacturer wouldn’t want to take advantage of this to optimize performance after production, improve customer satisfaction, and create new revenue models?

To learn more about Simcenter Engineering Services, visit our website or email us at engineeringservices.sisw@siemens.com.

To learn more about how Simcenter supports EV battery development, click here.