Foot on the Siemens Xcelerator: Simcenter helps Hendrick Motorsports win the NASCAR Cup

Last Sunday Hendrick Motorsports driver Chase Elliott won the NASCAR Cup in the most spectacular fashion. Elliott’s #9 car had been due to start on Pole Position, but after twice failing a pre-race technical inspection, was forced to start from the back of the pack. In what had been described as “the drive of a lifetime” and a “miracle comeback” Elliott’s #9 car overtook the whole field to claim the sport’s premier trophy.

Elliott’s victory is a classic example of what I love so much about sport, those situations which competitors exceed all reasonable expectation(through a combination of blood, guts, talent and sheer determination) to claim improbable victories against all the odds. Even as a spectator, few things in life deliver the same sort of endorphin rush as these incredible sporting occasions.

However, it is easy to be distracted by that ALL of these victories (no matter how apparently improbable) are built on a base of hard work, consistency and constant improvement. And there isn’t a better example of that than Hendrick Motorsports, who claimed their 13th Championship with Elliott’s victory on Sunday. The last 11 of those Championships have been while partnered with Siemens Digital Industries Software.

Let’s look into the engineering story behind this incredible win

“36 product releases a year”

The NASCAR open garage policy means that cars and teams set up shop next to each other for the weekend. There are no walls or curtains; nothing separating them. And the garages are assigned by current points standings, meaning you are sure to be next to the cars you are fighting with week-in and week-out as you try to climb the standings and win a championship.

“What we do is like having a new product introduction every week for 36 weeks,” says Jim Wall, director of engine programs at Hendrick Motorsports. “You have to re-invent yourself every week, understanding the advantage is getting your ideas to the race track before someone else does.”

The goal every week is to find something else no one else did, prove it digitally and get it on the car for the race next weekend: “Our product release cycle can be as short as three days,” explains Wall. “If we have a failure on Sunday, we’ve got to come up with a fix, produce parts and retrofit the fleet, usually before Wednesday night when the trucks get loaded with the race cars for next weekend’s event.”

In this most challenging of environments, Hendrick Motorsports have turned to the Siemens Xcelerator™ portfolio, the comprehensive and integrated portfolio of software and services from Siemens Digital Industries Software.

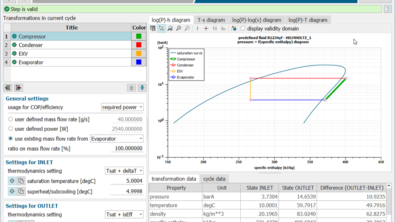

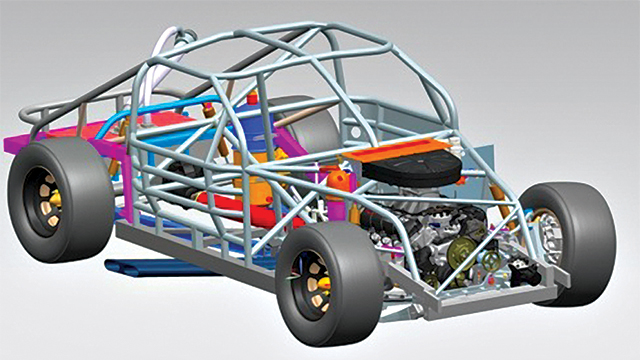

You could say that Hendrick Motorsports really do have their foot on the Siemens Xcelerator: The engine engineering team, the vehicle dynamics engineering team and many other groups use NX in their computer-aided design (CAD), computer-aided manufacturing (CAM) and CAE (integrated capabilities from Simcenter 3D) operations. They drive this information to their Teamcenter® software unified environment, which is used to coordinate and track versions and revisions, and has a number of workflows to automate review and release processes throughout the organization.

In addition to all of this, or the past five years Hendrick Motorsports have been using Simcenter STAR-CCM+ to perfect the aerodynamic performance of their car.

“Simulation is the key to winning championships”

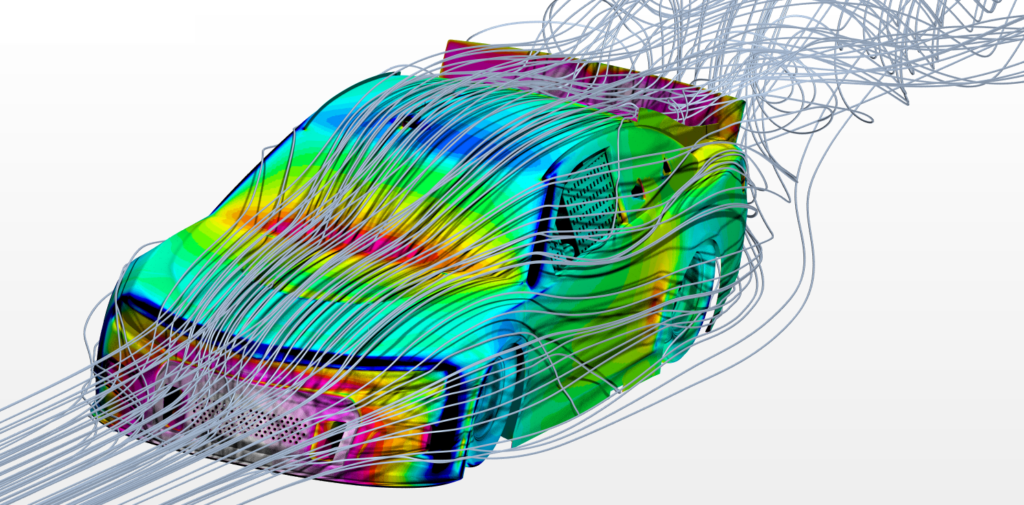

In 2015, Hendrick Motorsports needed a faster and more robust way to develop the aerodynamic packages for their cars. “We knew simulation was the key to winning championships, but we couldn’t afford for our engineers to spend their valuable time on manual tasks to make simulation work,” says Hendrick Motorsports aerodynamicist Scott Lusted. “We decided to switch to Simcenter STAR-CCM+ because of its effortless preprocessing.”

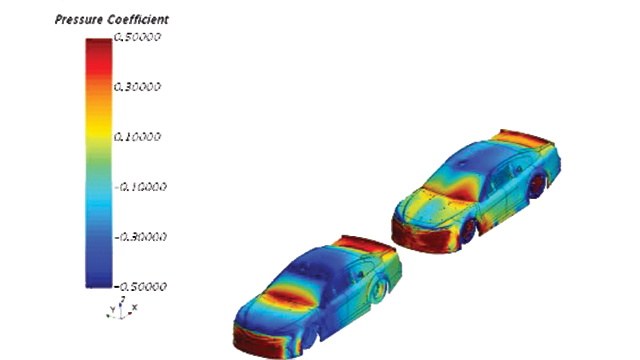

To squeeze out every bit of aerodynamic performance, engineers at Hendrick Motorsports look at every component of the car, from roof strips and spoilers to the front splitter, underbody and diffuser. Even the smallest design change can increase the top speeds that regularly exceed 200 miles per hour (MPH). This can make or break race performance. Precise engineering is critical so all the geometrical detail must be modeled in the simulations.

“With NASCAR rules and regulation constraints, we are under constant pressure to turn around simulations faster so that we can innovate,” says Lusted. “With Simcenter STAR-CCM+, we are able to generate CFD-ready geometry with near-zero human interaction time, and the high-quality mesh generated using surface wrapper is just as good as something that was hand-built.”

“Simcenter STAR-CCM+ is unique in that it delivers all stages of the simulation process into a single platform,” says Lusted. “This lets us completely automate the workflow from CAD to solution so that changes to a design can be evaluated with minimal manual effort. With automation and robust processes, our team saves 85 per cent of the time setting up the CFD runs, which enables our engineers to focus on the aerodynamics rather than the process behind it.”

“With high-fidelity simulation, we can gain better insight into performance in a fraction of the time and at a fraction of the cost of physical testing,” says Scott Lusted. “It lets us evaluate hundreds of designs quickly and gain a competitive edge before we even go to the track.”

“The key benefit that Siemens Xcelerator gives us is the speed of response to make a competitive change, to fix problems and to create more performance at the race track in a very tight window of time,” says Wall.

Of course, process is nothing without accuracy. Hendrick Motorsports are able to deliver fast and accurate CFD predictions that influence the design of the racecar:

“The predictive capabilities of Simcenter STAR-CCM+ are best-in-class. We can now develop car components using CFD. When we compare the results of the complex flow field against wind tunnel data, they correlate exactly,” says Martin Bester Aerodynamics Engineering Manager at Hendrick Motorsports

Congratulations and Chase Elliott and everyone at Hendrick Motorsports that helped inspire this incredible victory.