Unlock the power of predictive virtual testing with Simcenter 3D Smart Virtual Sensing

In the world of commercial vehicles, where reliability isn’t just a selling point but a promise to customers, we have worked with a leading commercial vehicle manufacturer to continue to push the boundaries of innovation. Behind the scenes of their latest breakthrough in durability testing lies a story of transformation that’s reshaping how we think about vehicle development and validation.

The challenge of tomorrow’s roads

Picture this: A heavy-duty truck traversing thousands of miles across varying terrains, carrying crucial cargo while facing countless stress points throughout its journey. Ensuring vehicle reliability isn’t just about meeting standards – it’s about exceeding them while advancing sustainability goals and reducing development time.

“Traditional testing methods, while proven, don’t give the complete picture for developing next-generation vehicles,” shares Xiaoting Kou, Senior Product Manager. “Manufacturers needed to see the unseen, measure the unmeasurable, and do it all while maintaining their commitment to efficiency and sustainability.”

A digital revolution in testing

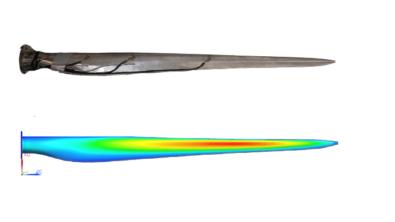

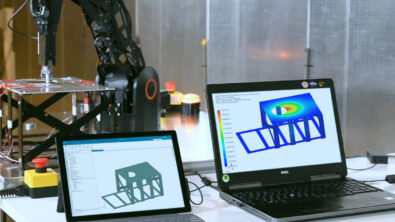

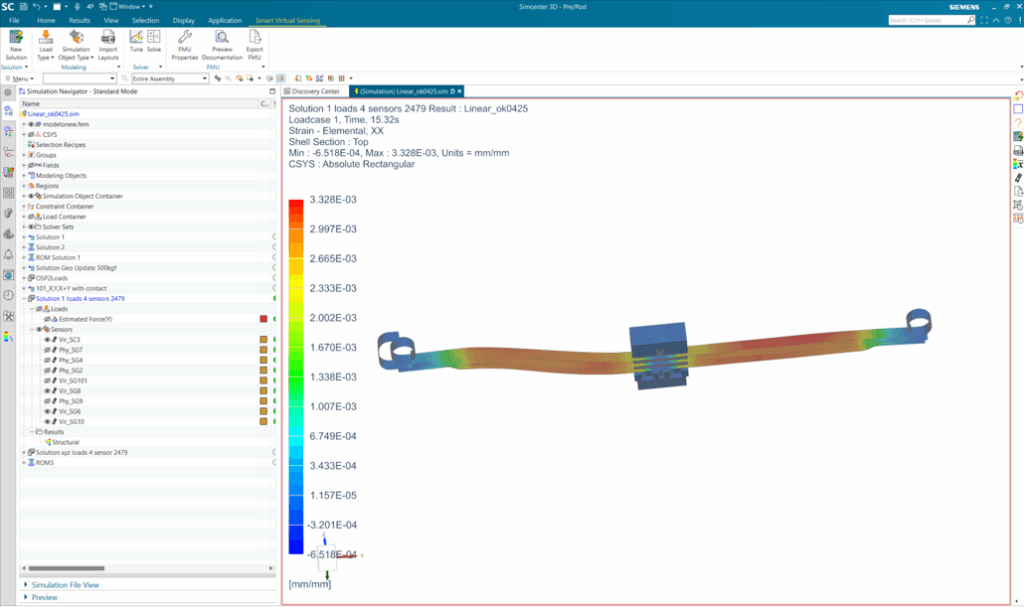

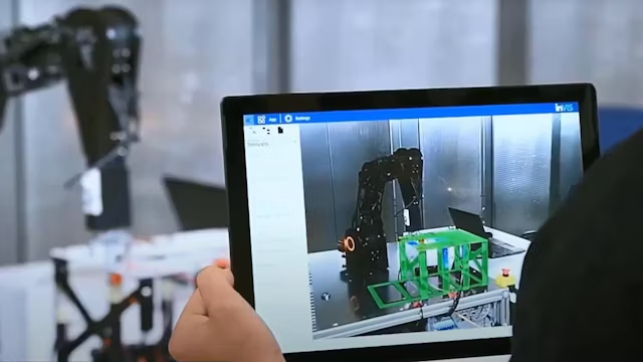

Enter Simcenter 3D Smart Virtual Sensing technology, a groundbreaking approach that’s transforming how we validate critical components like front leaf springs. Think of it as having thousands of invisible sensors working in harmony with physical ones, providing unprecedented insight into how vehicles perform under real-world conditions.

The innovation lies in the seamless blend of physical and virtual testing. Much like how weather forecasters combine satellite data with ground measurements to predict tomorrow’s weather, engineers now merge real-world sensor data with advanced simulation models. This approach doesn’t just test components – it predicts their behavior and potential wear patterns before they ever hit the road.

Where virtual meets reality

The transformation is perhaps best illustrated in the development of critical components, such as the front leaf spring. To design and validate such a key component, both rig testing and route testing are often required. Rig testing uses simplified load cases to validate component performance under controlled conditions, which can be performed and repeated by suppliers. While route testing aims to do the integrated validation by OEMs, it also helps to capture true loading patterns and environmental factors, which will provide baseline data for rig testing. Route testing is often costly and time-consuming as you need to instrument dozens of sensors on the vehicle and drive for hundreds of kilometers. “With smart virtual sensing, you can maximize the route testing efficiency with minimum physical sensors,” notes Xiaoting.

More importantly, this new approach bridges two crucial testing worlds: the controlled environment of laboratory testing and the unpredictable nature of real-world routes. The load prediction during route testing allows for accurate rig testing to reproduce the same loads. Alternatively, the route testing loads can serve as a starting point to develop constant amplitude load blocks, which would produce similar damage levels as those experienced during real-world applications. Since not all spring suppliers have the capability to perform random input testing on their rigs, this approach improves OEM-supplier collaboration by bridging that gap.

Beyond the test track

The impact of this innovation extends far beyond the testing grounds. By reducing the number of physical sensors needed while increasing the accuracy of predictions, commercial vehicle OEMs are not only optimizing development costs but also contributing to their sustainability goals. Each virtual test represents reduced material usage and energy consumption in the development process.

Smart virtual sensing technology not only addresses current challenges but also paves the way for future innovations in online prediction durability engineering. It has the potential to enable maintenance before issues occur, transforming maintenance from reactive to truly proactive, known as predictive maintenance.

The road ahead

As transportation continues to evolve, with electric and autonomous vehicles on the horizon, the ability to understand and predict vehicle behavior becomes increasingly crucial. This innovative approach to testing and validation isn’t just about building better trucks – it’s about paving the way for a more sustainable and reliable transportation future.

Want to learn more about how innovation is reshaping the future of transportation? Explore the capabilities of smart virtual sensing for measuring the unmeasurable:

WHITE PAPER

Measuring the unmeasurable