Digital twin for green aviation: Pioneering cryogenic hydrogen systems

The digital twin for green aviation plays a significant role in supporting the decarbonization, with the European research program Clean Aviation spearheading innovative initiatives. Among these, the NEWBORN project, led by Honeywell International s.r.o., stands at the forefront of innovative propulsion technologies. This collaborative effort brings together industry leaders and researchers to develop a revolutionary fuel cell system demonstrator for aviation applications.

Siemens is responsible for the digital twin for sustainable aviation and modeling tools development, providing essential support throughout the project’s lifecycle.

At the heart of this initiative, is the development of an advanced digital twin for green aviation, namely for cryogenic hydrogen systems. The project brings together key partners including TEST-FUCHS GmbH, who contributes their expertise in cryogenic LH2 tank and hydrogen supply systems.

Marc Hazenbiler, representing TEST-FUCHS Aerospace Systems GmbH as a key technical expert, together with Antoine Delacourt, from Siemens Digital Industries Software Systems Simulation R&D, presented their simulation works in NAFEMS NWC25.1

Technical challenges and the solutions provided by digital twin for green aviation

A cryogenic hydrogen system faces several critical challenges in managing hydrogen effectively. The fuel must be maintained in a liquid phase within a cryogenic tank while being delivered to the fuel cell anode as a gas at precise pressure and temperature specifications. The design incorporates innovative solutions, including:

- Specialized “cold box” and “hot box” attached to the cryogenic tank

- Advanced leak prevention systems

- Sophisticated control mechanisms for safety and reliability

- Optimized heat flux management to minimize hydrogen losses

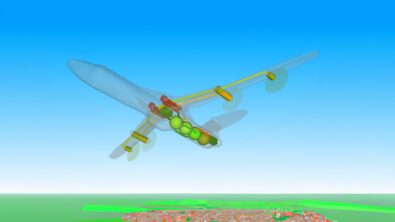

Below is a picture of the comprehensive integrated system architecture and the respective contribution of the 13 NEWBORN partners.

The presentation by Marc Hazenbiler highlights TEST-FUCHS Aerospace Systems GmbH’s core contribution to the NEWBORN project: the hydrogen tank supply subsystem, with particular emphasis on cryogenic valve technology. Drawing on their three decades of expertise in designing and manufacturing cryogenic components, TEST-FUCHS brings their well-established reputation in this specialized field to advance the development of hydrogen-powered aviation systems

The presentation also highlights how Simcenter Systems Simulation tool (Simcenter Amesim) is used for mastering complexity from the early design stages, evaluating and balancing potentially conflicting performance attributes from the early development to final performance validation and controls calibration.

We are satisfied by the alignment between the Simcenter Amesim valve model and the test results

Marc Hazenbiler | Simulation and Calculation Engineer at TEST-FUCHS

Project integration and validation

The simulation model is part of a larger ecosystem that includes multiple subsystems working in concert. Such a digital twin for green aviation encompasses everything from power distribution to thermal management, creating a comprehensive virtual representation of the entire system.

The digital twin validation progresses from component testing to full system integration, building confidence in the model’s accuracy. First test at component level gives encouraging results, as shown in the presentation of Marc Hazenbiler and Antoine Delacourt, while final global system test validation remains the objective of the project, in the year 2026.

Digital twin will run parallel to the physical demonstrator, demonstrating the complementary nature of both approaches before advancing to a flying demonstrator phase.

Pipistrel, one of the NEWBORN project partners

Pipistrel Vertical Solutions (PVS) is Pipistrel’s R&D and Certification arm, specializing in developing battery systems, power controllers, and electric motors for aircraft. It is the only company globally with EASA approval for propulsion-class batteries for commercial aviation. As part of the NEWBORN project, Pipistrel is tasked with integrating and testing a demonstrator, focusing on sustainable flying solutions and advancing hydrogen fuel cell research. This task highlights PVS’s expertise and the importance of utilizing world-class tools such as Simcenter Systems Simulation for advanced digital twin for green aviation development.

We are happy with Simcenter Amesim and we are trying to convince other colleagues from Pipistrel to use it.

Jernej Drofelnik | Pipistrel Research Manager

Conclusions and Future Outlook

The development of this digital twin represents a significant step forward in aviation’s green transformation. The simulation work has already demonstrated its value in several key areas:

- Quick and efficient system performance assessment

- Enhanced design process support

- Successfully addressing phase transition challenges

- Promising initial validation results

This innovative approach to hydrogen system development could pave the way for future flying demonstrators, marking a significant milestone in sustainable aviation technology.

Antoine Delacourt, a Research & Technology Development project engineer at Siemens, has contributed to this blog.