How does a controllable pitch propeller (CPP) work?

Controllable pitch propellers (CPP) are a sophisticated type of marine propulsion system where the blades can be rotated to change the pitch. This adjustment allows for optimal performance under varying conditions such as load, weather and maneuvers, ensuring maximum efficiency.

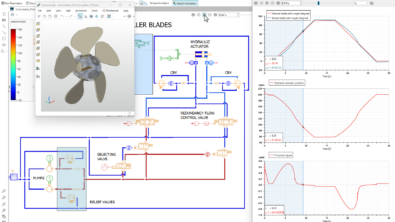

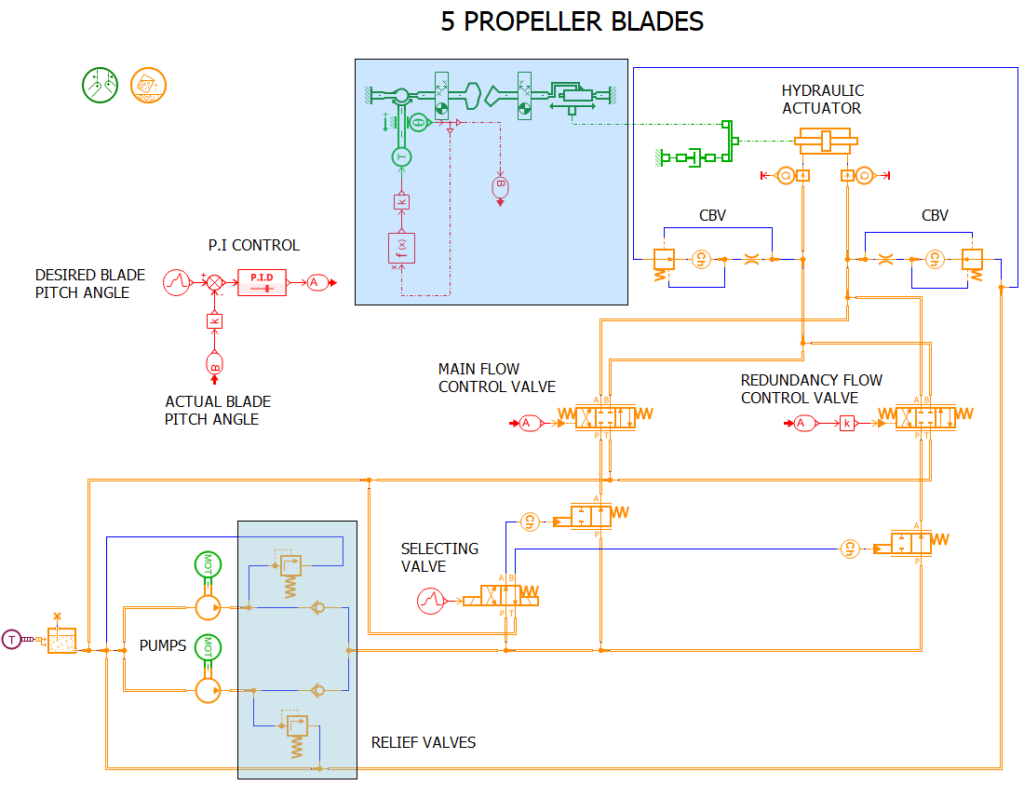

In this blog, we will dive into the components, operation and simulation results of a CPP system, providing a comprehensive understanding of its engineering. The sizing of the hydraulic circuit (actuator, valves, piping, etc.) during the preliminary design phase of a controllable pitch propeller system is done using Simcenter Amesim.

Components of a controllable pitch propeller

In a simplified CPP system, we count the following key components:

- Two pumps in parallel – they provide the necessary hydraulic power to the system

- Selecting valve – it selects the appropriate flow direction valve. By default, the main valve is used, while the second valve serves as a redundancy

- Flow direction valves – there are two proportional valves—one main and one redundant. These valves control the hydraulic flow to the actuator

- Relief valves – they protect the system from overpressure by releasing excess pressure

- Counter-balancing valves (CBV) – they maintain stability within the hydraulic system

- Hydraulic actuator – it moves the blades to the desired pitch angle

In our simulations, the main parameters of the system are as follows:

- Propeller diameter – 2 meters

- Hydraulic pumps – each pump has a displacement of 50 cm³ and operates at 1170 rpm

- Relief valve – tuned to a maximum pressure of 150 bar

- Flow direction valves – capable of handling 150 L/min with a 1 bar pressure drop at maximum opening

- Main pipes diameter – 30 mm

- Hydraulic actuator – features a total stroke of 360 mm, a piston diameter of 300 mm and a rod diameter of 50 mm

- Total translating mass – 300 kg per blade, with a weight of 140 kg and an inertia of 6.42 kg·m² for a single blade

Operation and control

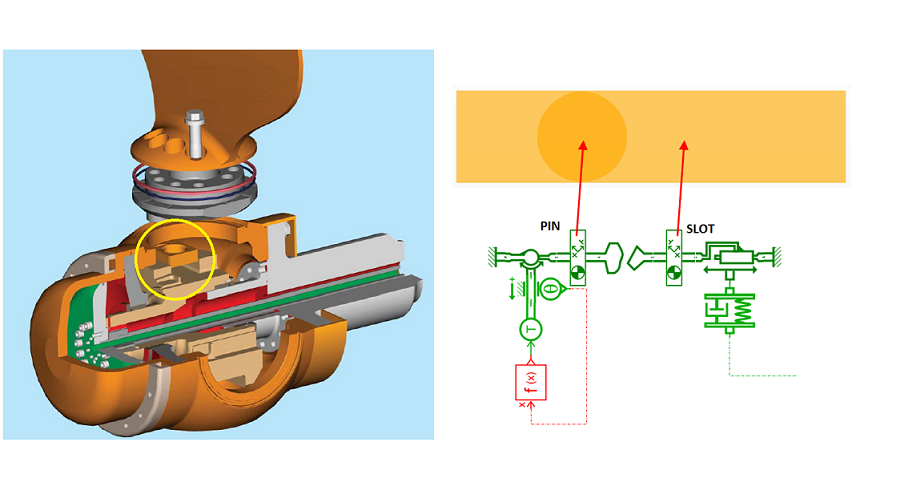

The operation of the controllable pitch propeller system is controlled by a proportional-integral (PI) controller. The desired blade pitch angle is compared with the actual angle and the PI controller generates a control signal to adjust the flow direction valve accordingly. This valve controls a hydraulic actuator that rotates the blades using a pin-slot mechanism. This pin-slot mechanism consists of two mechanical bodies connected through a 2D contact model, representing the geometry of the pin and slot.

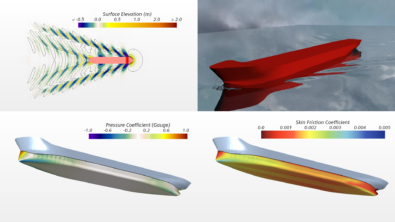

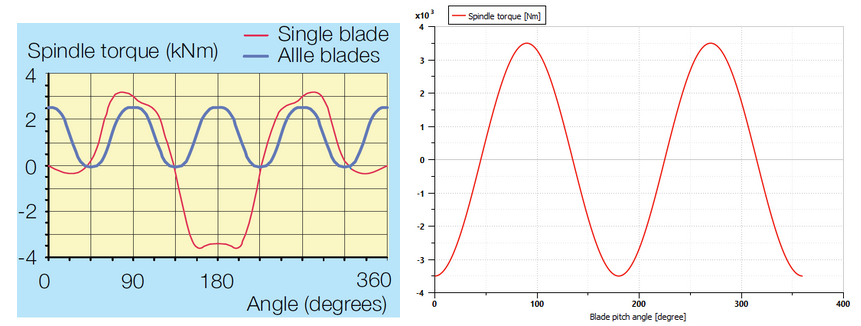

A hydrodynamic torque is imposed on the blade as a function of the blade pitch angle.2 This torque can be customized using a torque table, which can depend on various parameters such as propeller rotary velocity, ship velocity and blade geometry. Additionally, it could be extracted from Simcenter STAR-CCM+ simulation results.

Simulation results and conclusion

The simulation results demonstrate the effectiveness of the hydraulic system in following the desired pitch angle. Here are some key observations:

- The hydraulic actuator displacement is influenced by the mechanical geometry of the system

- The PI control signal ensures that the flow directional valve size is sufficient to meet the pitch angle requirements

- The pressure and flow rate within the hydraulic actuator chambers are affected by the hydrodynamic torque, which varies with the blade pitch angle

The pressure evolution inside the hydraulic actuator chambers is correlated with the inlet pressure system and the hydrodynamic torque acting on the blade. The torque changes sign after 45° of blade pitch rotation, corresponding to the blade aligning with the rotary direction. This change influences the pressure values of the hydraulic actuator.

To conclude, controllable pitch propellers are crucial for efficient marine propulsion and system simulation is an efficient means of designing the system.

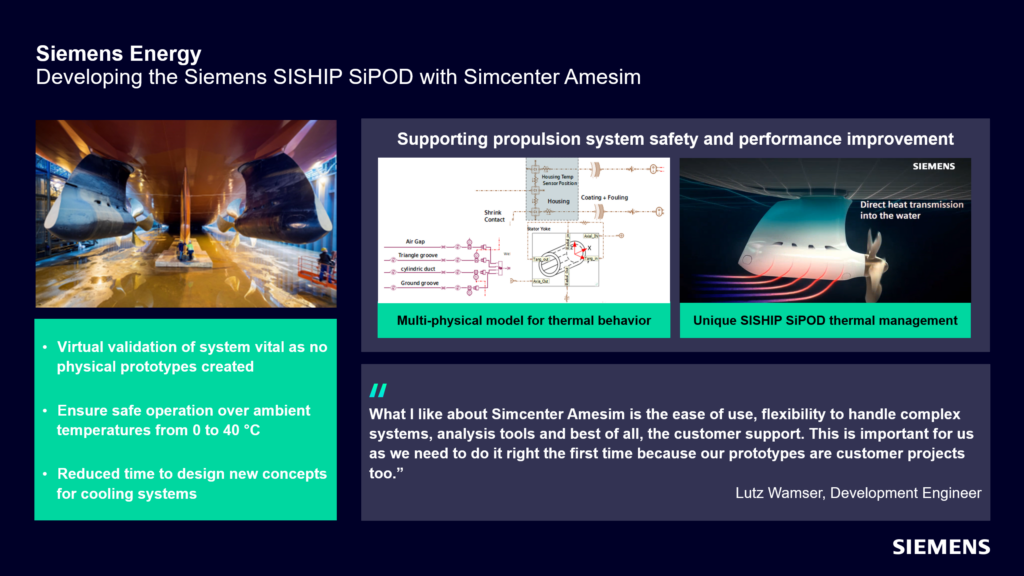

Siemens Energy applied a similar approach to support the development of the Siemens SISHIP SiPOD with Simcenter Amesim:

References

- MAN Energy Solutions, “Basic principle of ship propulsion”, 2018.

- MAN Diesel, “CP Propellers”, 2007.

- E. Ravina, S. Brina “Hydraulic circuit modelling of a marine controllable pitch propeller”, ITI Symposium, Dresden, Germany, November 2011.

- E. C. Tupper, “Introduction to Naval Architecture”, Butterworth-Heinemann, Fourth Edition 2004.

- J. S. Carlton, “Marine Propellers and Propulsion”, Butterworth-Heinemann, Second Edition 2017.

- H. D. McGeorge, “Marine Auxiliary Machinery”, Butterworth-Heinemann, Seventh Edition 1995.