Advancing Induction Machine and Transformer Workflows – What’s new in Simcenter 3D Low Freq EM 2512

Faster set-up for an induction machine

Induction machines (IM) are the workhorse of industry. Known for their ruggedness, cost-effectiveness, and ability to achieve very high speeds, they are finding new applications in electric vehicles (EVs). Their use in EVs helps reduce dependency on expensive and geopolitically sensitive rare-earth magnets.

However, setting up an IM simulation is a challenging task. It requires defining not only the stator circuit, but also the squirrel-cage rotor bar circuit. If done manually, it is a complex and time-consuming process.

The new 2512 release of Simcenter 3D Low Freq EM makes winding and circuit definition easier, allowing the user to:

- Create a squirrel-cage rotor bar circuit component that can be periodic.

- Leverage nested subcircuits like windings to simplify circuits

- Automatic creation of circuits via scripts.

To see these capabilities in action, check out the following video

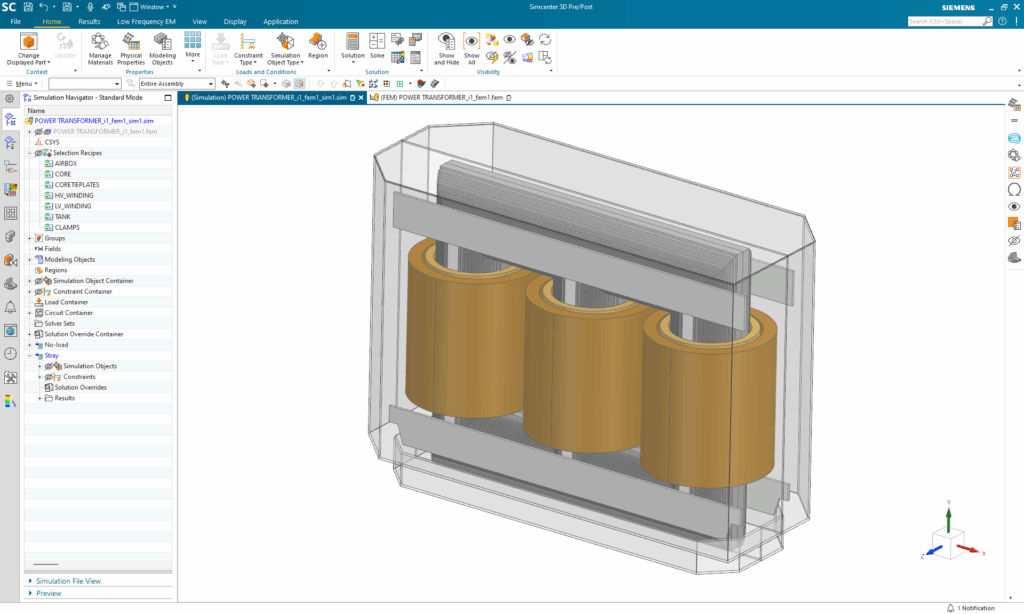

Enhancing analysis for power transformers

The explosive growth of AI is driving the need for “AI factories”, where energy is converted into AI tokens. Since AI data centers are energy-intensive, power transformers play a critical role in the efficient delivery of the massive amounts of energy required. Even a marginal efficiency improvement in these transformers can lead to substantial energy savings over their typical lifespan of more than 40 years. They are still expected to operate efficiently at over 99.5% even under dynamic conditions (Power swings of 40–75% within an hour) inherent in AI data centers.

As OEMs strengthen their transformer offering for these dynamic loads, they must leverage advances in materials and designs. For the core, we are seeing better grain-oriented electrical silicon steels (GOES/GOSS), which offer higher saturation, lower loss, and reduced noise.

Let’s take a closer look at how flux behaves within a transformer core. It comprises the limbs, where the windings are wound, and the yokes, which link the flux between the limbs to complete the magnetic circuit. As shown in the next video, most of the magnetic fluxes in the core are primarily alternating (or pulsating). In an electrical cycle, the flux at a point increases sinusoidally to its peak, then decreases to zero, and repeats the process in the opposite direction, creating an alternating unidirectional flux.

Because of this, transformer ferromagnetic core materials are optimized to carry unidirectional flux. This is why grain-oriented electrical silicon steels (GOES/GOSS) are used, as they have an “easy axis” for flux flow. In contrast, for rotating electric machines, where there is no clear preferred flux orientation, non-oriented electrical silicon steels (NOES/NOSS) are commonly used.

However, as you might have noticed in the same video, it gets a bit complicated in the regions where the limbs meet the yokes – known as T-joints. Here, the fluxes rotate while maintaining their magnitude. This means fluxes must cross the “hard axis,” where more anisotropic energy is expended than in the easy axis. The associated iron loss is approximately 1.5 to 2 times higher than that of alternating flux, resulting in significant iron loss hotspots.

Transformer designers must carefully design cores, including T-joints, to reduce noise and iron losses. Consequently, the new 2512 release of Simcenter 3D Low Freq EM now supports phasor results for the Time-Harmonic AC solver. This feature is primarily used in transformer and AC loss analysis applications. In the video above, it helped animate the flux-density field over phasors, illustrating the need for GOES and why T-joints are the hotspots for iron loss.

This enhancement further strengthens Simcenter 3D’s comprehensive EMAG and NVH workflows for detailed transformer design, covering:

- Efficiency: Analyzing iron, winding, and stray losses

- Hum: Investigating core magnetostriction

- Structural: Performing Lorentz short-circuit force analysis on the winding assembly.

Ready to Explore?

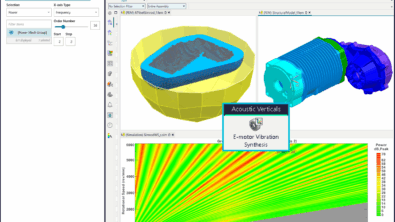

The 2512 release improves Low-Frequency EM in Simcenter 3D. It simplifies complex circuits, such as squirrel-cage rotor bars, and provides better insights into transformer and AC loss analyses by supporting phasors for Time-harmonic AC post-processing. It also enhances the import of 3D e-motor models from Simcenter E-Machine Design.

To see how Simcenter 3D Low Freq EM can transform your simulation workflows, reach out to us or our support team!