About vehicle dynamics and the 3 sides to every story

Ride comfort and vehicle dynamics are major characteristics to define the perceived quality of a car. Chassis performance significantly influences a customer’s buying behavior (or not). But your perception of driving feel, might be different to my observation.

“There are three sides to every story:

your side, my side, and the truth.”

We’re all individuals with different personalities and expectations. And none of us is right or wrong. That’s great from individual point of view. But how can a manufacturer design for a chassis or vehicle that thrills his entire customer database? Is that even possible?

Not so long ago, manufacturers made an estimated guess based on a multitude of subjective evaluations. Test divisions focused on measurements, simulation divisions made virtual predictions. But that was then.

Chassis performance closes the gap between driver feel and objective metrics

As you can read in the Vehicle Dynamics International Magazine, engineering departments of today took giant leaps by combining the previous siloed test and simulation departments. They found new techniques to close the gap between driver feel and objective metrics, and expanded vehicle dynamics testing through model identification and usage.

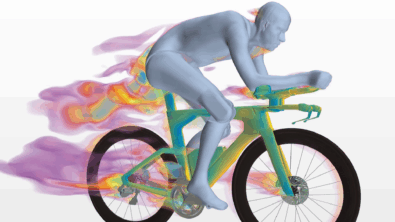

Chassis engineers developed test-based solutions to identify and drive simulation models for validation and analysis of functional performance. At the same time, simulation models were deployed to maximize the testing capabilities in terms of measurement robustness, precision and detail. They also call it ‘Test for Simulation’ or ‘Simulation for Test’. Either way, they ensure the vehicle has precisely the desired requirements. This is done by translating brand identity in specific driving feel and enhancing safety and comfort with increased efficiency and at reduced cost.

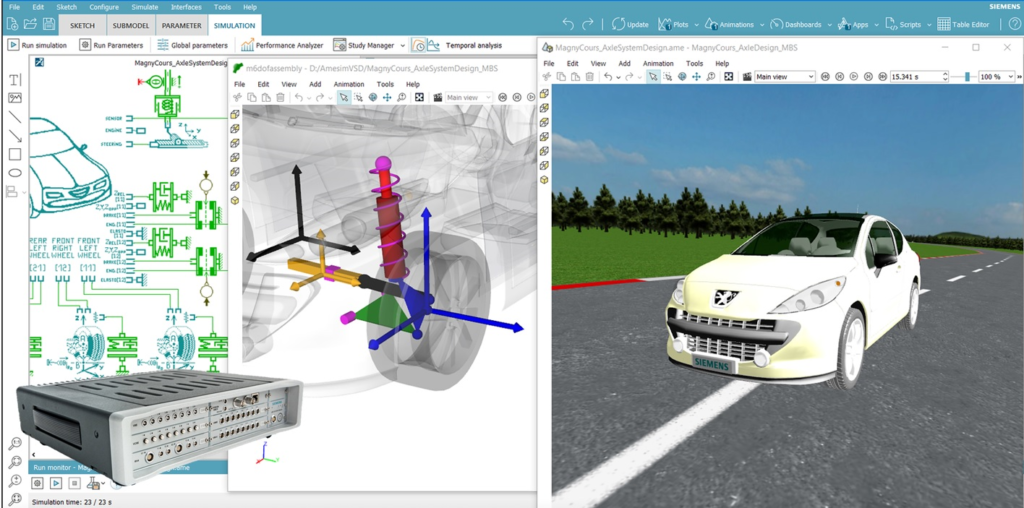

To objectively quantify chassis design and full vehicle performance, the experts of Simcenter Engineering deploy model-driven test solutions. Using models of various complexity, the engineering specialists speed up the testing process (efficiency) and enhance the testing by enabling higher precision and increased robustness of the test results (quality). The models that are used to drive this enhanced testing can range from detailed multi-body-simulation to simplified vehicle representations such as the bicycle model.

For example, on-center performance. You can link subjective driver feeling and objective measurements. But how? For more info, this webinar demystifies on-center performance and explains how to quantify changes due to chassis, body or tire modifications and link objective data to subjective evaluation.

Tire modeling in a full vehicle simulation context

Likewise, forward-thinking tire modeling teams develop tire testing methods to parameterize simulation models of the tire. These are used in full vehicle simulation for different performance attributes such as vehicle dynamics, control system development and comfort. The methodology delivers models that fit the requirements and improves the correlation between simulations and vehicle tests.

We all know that tires are a crucial component of the chassis and substantially influence the vehicle dynamics. Read this blog post to find out how much is ‘substantially’ and what we can do to make sure the tire positively contributes to the overall driving safety and behavior

Test for simulation, simulation for test: the same idea. It brings engineers a tire modelling methodology rather than a tire modelling software tool only.

More information:

> Vehicle dynamics solutions

> Vehicle dynamics International Magazine