Revolutionizing EV drivetrain design: Addressing NVH and design complexity

The imperative of quietness in electric vehicle

The rapid adoption of Electric Vehicles (EVs) marks a significant shift in automotive engineering, promising sustainable and efficient transportation. At the core of these vehicles are Electric Drive Units (EDUs), which, unlike their internal combustion engine counterparts, operate with minimal inherent noise. This intrinsic quietness brings the Noise, Vibration, and Harshness (NVH) performance of all other components, particularly the gear train, into sharp focus.

Gear whine is a tonal noise originating from the variation of stiffness during the gear mesh cycle, directly impacting passenger comfort and the perceived quality of the EV. More information on the topic of gear whine can be found in previous published blog post. The demand for high-speed, high-reduction gear drives for optimal performance and efficiency in modern EVs further exacerbates this challenge, making optimal NVH performance a critical design goal. This blog will summarize two conference papers that introduces a new systematic approach to design EDUs for optimal efficiency, durability and NVH performance.

The dual challenge: Navigating design complexity and performance optimization

Developing advanced gear trains for EVs presents engineers with a formidable set of challenges. Our research identifies two primary problem statements that hinder the efficient and effective design of these crucial components:

- Complexity of design space exploration

The initial stages of EV drivetrain development involve exploring a vast array of potential gear train architectures, including both layshaft and planetary configurations. Each configuration offers unique trade-offs in terms of packaging, efficiency, durability, and NVH. Manually navigating this complex design space, evaluating numerous layout- and component- level parameters, and optimizing for multiple, often conflicting, objectives (such as minimizing mass, reducing bearing forces, achieving high power density and minimizing transmission errors) is an incredibly time-consuming and iterative process. This often leads to prolonged development cycles and can result in sub-optimal design choices due to the sheer scale of possibilities.

- Mitigate impact of real-world variability on performance

While optimal gear designs are crucial for smooth operation, the real-world manufacturing process and changing loading conditions introduces variations and errors that can significantly degrade NVH performance. Traditional optimization methods often struggle to account for these manufacturing realities, leading to designs that perform well in simulations but fall short in production. The challenge is twofold: how to find an optimal gear microgeometry that delivers superior NVH performance, and simultaneously, how to ensure this design remains robust and stable even when faced with inevitable manufacturing imperfections. This necessitates a methodology that is not only efficient but also resilient to real-world variability.

Our solution: An automated framework for gear train design optimization

To overcome these significant challenges, our papers introduce a novel automated gear train design software tool. This innovative framework called Simcenter 3D Motion Gear Design Optimization provides a systematic and efficient methodology for the development of EV drivetrains, from initial concept to refined component design. Our approach is built upon the intelligent integration of commercially available multibody simulation and optimization platforms, enabling a comprehensive exploration and refinement process.

Key pillars of our methodology

- Layout-level optimization for efficiency, strength and durability

The first step focuses on the macro-level design parameters. The tool efficiently explores diverse gear drivetrain architectures, including both layshaft and planetary configurations. During this stage, the primary objectives are to minimize overall mass and bearing forces, laying a robust foundation for the drivetrain. The automated exploration of drivetrain configurations significantly reduces the time and effort traditionally required to identify promising layouts that meet fundamental performance requirements.

- Component-level microgeometry refinement for optimal NVH

Following the layout optimization, engineers typically optimize macro- and microgeometry at component level, which is an iterative and time-consuming approach leading to sub-optimal designs. The Simcenter 3D Motion Gear Design Optimization framework will optimize gear macro and microgeometry considering the transmission system level behavior. This crucial stage is dedicated to reducing transmission errors, which directly translates to improved NVH performance. By refining parameters at this detailed level, the tool ensures that the selected gear train not only meets efficiency and durability targets but also delivers the quiet operation essential for a premium EV experience.

- Robustness analysis to mitigate impact of variability

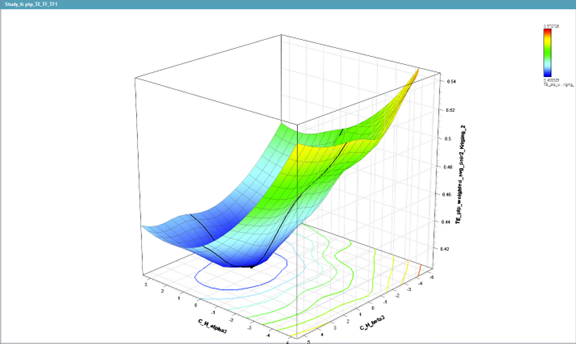

A significant hurdle in gear optimization is the computational time required for detailed simulations. To overcome this, we integrate an AI-based simulation predictor tool within this multi-objective optimization framework. During the design space exploration an AI model will be trained automatically and gradually replacing the responses predicted by expensive simulations with responses by that AI model. This integration drastically reduces the computational time needed for optimization without compromising accuracy. By leveraging AI, we can explore a wider design space more rapidly, allowing to assess the variability of the design parameters.

This is achieved by considering manufacturing variations through stochastic distributions of the microgeometry design parameters. This allows us to understand how sensitive the design is to these variations and to ensure that the optimized solution remains effective and stable under real-world dynamic and manufacturing conditions.

The effectiveness of Simcenter 3D Motion Gear Design Optimization tool has been rigorously demonstrated through detailed case studies, provided by Hyundai Motor Company and General Motors. These studies showcase significant improvements in key performance metrics, such as transmission error and power density, compared to baseline designs.

Join us at the VDI Conference!

We invite you to learn more about our groundbreaking research and its implications for the future of EV drivetrain design. Our team will be presenting two distinct, yet complementary, papers at the upcoming VDI conference.

- On Friday September 12, 2025 at the 11 International VDI Conference on Gears 2025 in Garching near Munich (Germany), Jonas Verhoogen presents our paper on a methodology to optimize gear microgeometry for best NVH performance while mitigating the impact of manufacturing errors [2] (9:00-9:30 CEST in Lecture Room B).

- Then at 11:00-11.30 in Lecture Room B see Daehyun Park present our paper on automation of high power density gearbox design encompassing layshaft and planetary gear train layouts across a wide range of operating conditions [3] (11:00-11:30 CEST in Lecture Room B).

Please refer to the VDI conference website for more information.

We encourage you to attend both presentations to gain a comprehensive understanding of our advancements in achieving superior NVH performance and efficient design workflows for electric drive units. We look forward to engaging with you and discussing how these innovations can drive the next generation of electric mobility.

References

[1] A. Volk and M. Leighton, “Integrated Development Program for Electrified Drivetrains,” ATZ worldwide, 2020.

[2] D. Park, A. Rezayat, and Y. Gwon, “Automation of high-power density gearbox design encompassing layshaft and planetary gear train layouts across a wide range of operating conditions”, VDI Conference on Gears 2025.

[3] J. Verhoogen, H. Y. I. Du, B. Li, H. Xu, “Microgeometry optimization of an E-Drive Unit using system level multibody simulation for best NVH performance while mitigating the impact of manufacturing errors,” VDI Conference on Gears 2025.