Engineering the past: Bringing a vintage Ju 52 aircraft back to life with the digital twin

The roar of a Merlin engine fills the air as a Spitfire soars through the sky, a powerful symbol of a bygone era. To the spectators below, it’s as if the aircraft has leaped straight out of the pages of history, a living testament to the bravery and innovation of those who flew and built these machines during the darkest days of the Second World War. But beneath the polished aluminium skin and iconic roundels lies a story far more complex—a story of preservation, restoration, and the delicate balance between history and modernity.

Many of these historic aircraft, like the Spitfires, Hurricanes, and Mustangs, have seen countless hours in the air and on the ground. As time takes its toll, the challenge of keeping them airworthy becomes ever greater. Components age, materials degrade, and the demands of modern aviation safety mean that restorers often face difficult decisions. Should a corroded wing spar be repaired or entirely replaced? How much of the original fabric covering can be saved? Each choice walks a fine line between maintaining the aircraft’s authenticity and ensuring it can still take to the skies.

Over the decades, many of these aircraft have undergone extensive restoration, with old parts swapped for new, sometimes even requiring entire airframes to be reconstructed from scratch. This raises the question: when does an aircraft cease to be an original and become a replica? Yet, for many enthusiasts and historians, these machines, whether they contain original parts or not, remain living connections to the past, carrying the spirit of those who once flew them into a modern world that still looks up in awe.

We live in a relatively privileged time, still within touching distance of the early golden years of aviation. But as time progresses, the “original” parts of these aircraft will erode further, and we must contemplate how future generations will enjoy these machines once there is nothing left of the originals—or when the originals are no longer safe enough to fly under modern aviation regulations.

Reviving a legend: An inside look at AeroFEM’s Junkers Ju 52 Project with Danny Wadewitz

In the aviation world, few aircraft hold the iconic status of the Junkers Ju 52. Known fondly as “Tante Ju” (Auntie Ju), this trimotor legend first took to the skies in 1932, quickly earning a reputation for reliability and endurance. With its distinctive corrugated metal skin and robust design, the Ju 52 became a workhorse for airlines and cargo operators alike, connecting remote regions and opening up air travel in places where it had once been impossible. (Some wartime variants of the Ju 52 were equipped with Siemens K4 Autopilots).

But as beloved as the Ju 52 is, time hasn’t been kind to it. By 2018, the few remaining operational models in Europe were grounded as the result of a tragic accident. This serves as a stark reminder that even the most enduring designs must eventually meet modern airworthiness standards. This is where AeroFEM GmbH, a Swiss engineering firm with a passion for aviation history, stepped in. Their ambitious mission? To bring the Ju 52 back to life—not just as a museum piece, but as a fully functional aircraft capable of meeting today’s stringent aviation regulations.

In our latest podcast episode, we sit down with Danny Wadewitz from AeroFEM to delve into the challenges and triumphs of this remarkable project. From reverse engineering an aircraft whose original blueprints were lost to history, to the painstaking process of selecting modern materials that could stand in for those used nearly a century ago, Danny takes us through the technical and emotional journey of reviving Tante Ju.

A Herculean task: Meeting modern standards with a vintage aircraft

The task of modernizing the Ju 52 was nothing short of Herculean. The original aircraft had been designed without the aid of computers or modern design tools, relying instead on paper, pencils, and slide rules. To meet today’s airworthiness standards, AeroFEM needed to reduce the aircraft’s takeoff weight from 10.5 tons to 8.6 tons—a nearly impossible task in aviation terms.

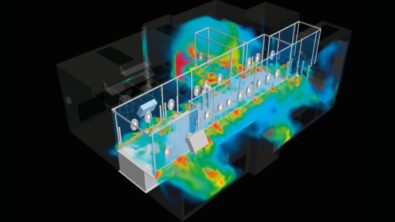

Danny walks us through how his team used Siemens’ Simcenter suite, a set of advanced simulation and engineering tools, to reverse engineer the Ju 52 from scratch. This involved 3D-scanning two existing Ju 52 aircraft—both inside and out—and transforming the millions of data points into a detailed digital model. With this model in hand, they could run rigorous aerodynamic and structural analyses, ensuring that their recreation of the Ju 52 would not only meet modern safety standards but also preserve the integrity of the original design.

Surprises and setbacks: What AeroFEM learned along the way

One of the most surprising discoveries during the project was just how little room there was for optimization. Despite the advancements in modern technology, the original engineers had already pushed the design to its limits. “The engineers at the time knew what they were doing,” Danny notes in our conversation, underscoring the remarkable quality of the original Ju 52 design.

Yet, the project wasn’t without its setbacks. Although AeroFEM made significant strides in recreating the Ju 52, the project ultimately didn’t proceed to flight testing due to funding constraints. But as Danny shares in the podcast, the work was far from in vain. The digital model they created now serves as the definitive record of the Ju 52’s design, preserving its legacy for future generations and offering invaluable insights for future aviation projects.

Tune in to learn more

In this episode of the Engineer Innovation podcast, Danny Wadewitz gives us an insider’s view of the engineering challenges, the emotional highs and lows, and the lessons learned from the Ju 52 project. Whether you’re an aviation enthusiast, an engineering buff, or someone who simply appreciates a good story of perseverance, this conversation is one you won’t want to miss.

Join us as we explore how AeroFEM managed to bridge the gap between past and present, proving that even in the age of digital design, there’s still so much to learn from the engineering marvels of history.