Let’s not forget why superior vehicle durability matters

We witness many new trends and innovations in the automotive industry, and that’s exciting! But that doesn’t mean we should forget about some standard engineering disciplines. Among them is vehicle durability.

Vehicle durability is as needed now as it was 20 years ago. The difference today is that we can rely on new technologies to enhance durability assessments. The discipline has grown with the rest of the industry, embracing digitalization. This allows the leverage of artificial intelligence (AI), the delivery of more accurate insights faster and earlier in the design cycle, and the ability to address the challenges of electrification.

In case you are still not convinced, here are 5 major reasons why vehicle durability should not be put aside:

Consumers want reliable vehicles. Don’t you?

What would be a good car for you? The one with a cool design? The one that implements the latest and greatest technology?

If you ask Google, the answer is straightforward: a good car is a reliable one. I typed several query variants in the well-known search engine. I wanted to find out which were the “best cars” or the “top 10 vehicles”. The search consistently returned results that listed the “10 most reliable cars” or the “most durable cars”.

The semantic shift from “good” to “reliable” or “durable” when the adjective qualifies a car is not coincidental. The search bots from Google are trained to identify the search intent of users. The bots return those lists as they understand that you meant to search for the most reliable car.

Year after year, independent companies, consumer groups and the specialized press publish their ranking and reviews of the top cars of the year. Consumer Reports in the US, JD Power and Motorway in the UK and Autokauf in Germany are just a few examples of the many companies, websites or magazines that judge the value of a car based on the frequency of breakdowns or incidents. Their sources and methodologies may differ but the opinions they express and the outcome of their investigations greatly influence consumers and car buyers.

The reported reliability incidents range from component failure due to fatigue to faulty electro-mechanical parts. In a case study, we reported how Nissan relies on the Simcenter end-to-end solution for test-based vehicle durability engineering to maintain high-quality standards and enhance its brand value.

We test more and more electronic components and less mechanical parts. The collaboration with Siemens is essential to adapt to these changes and to validate these new components.”

Arturo Barreu, Powertrain Durability Test Engineer Function and Durability Department NTCE-S

Hybrid and electric vehicles are not exempt from durability and reliability evaluation

New vehicle types are no longer designed for the early adopters who will be forgiving on defects and repairs. As those vehicles become mainstream products, it is essential that they meet consumers’ expectations in terms of reliability. Yet, the durability engineering of hybrid and electric vehicles poses some new challenges. Those include dealing with battery durability, conflicting performance requirements and generalized usage of lightweight materials.

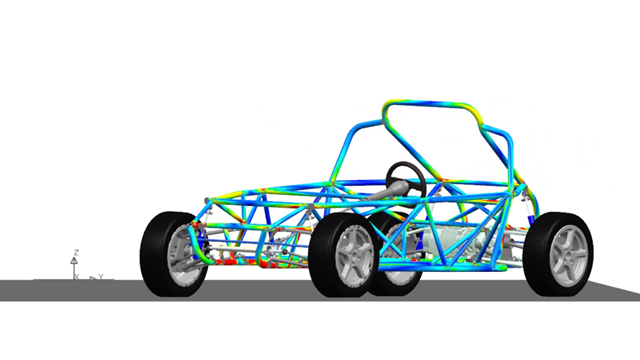

Manufacturers need to assess whether using lighter components, which will help increase the driving range, will not damage the car’s durability performance. They must also deal with the battery weight, which modifies the vehicle’s load distribution. This is what our engineers at Siemens did. Using Simcenter solutions, they tested the durability performance of the Simrod, an electric vehicle, on a test track.

Weight loss is a trend that impacts vehicle durability performance

Whether to increase the driving range or to reduce fuel consumption, lightweight design and materials are essential to meet targets. However, they should not come at the expense of long-lasting parts and components. The Simcenter finite element-based solving capabilities for composites, together with a new durability solver approach, allow you to correctly analyze the influence of progressive damage. You can develop a damage-tolerant, lightweight design that performs well under multiple loads with variable amplitudes. This proven approach applies to short and endless fiber re-enforced plastics as well as to adhesive structures.

The global market for used cars remains strong

The used car market is projected to reach over 1.5 trillion U.S. dollars in 2027, up from 1.2 trillion in 2020. This represents a compound annual growth rate of around 3.2 percent across seven years. We live in an era of consumerism, but cars are still items that will easily find a second, third or even fourth owner. Cars are nowadays engineered to drive at least 200.000 kilometers, while some makes and models aim at an even higher number.

Modern durability engineering techniques are more efficient than ever

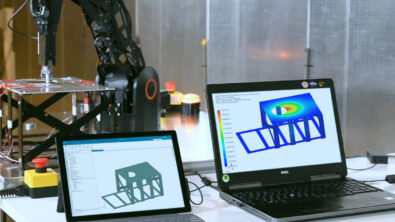

They leverage AI techniques to advance fatigue prediction. A holistic approach to vehicle durability engineering combines simulation and tests to help develop better vehicles. The digital twin, fed with real load data, supports durability engineers in their quest to meet targets without compromise while taking into account other performance attributes.

From road load data acquisition, load data mining, design optimization, and virtual product validation to quantifying the remaining useful lifetime, Simcenter solutions help deal with balancing issues faster, cheaper and earlier. The solutions guide you to find the right answers for engineering lighter, stronger and more durable vehicles in all the design stages.

You might also be interested in…

WEBINAR

Smart and automated road load data acquisition

WEBINAR HUB

Simcenter strength and durability engineering solutions

Comments

Comments are closed.

This post was a great read. Very informative and interesting!