Benefits of the Digital Thread in CPG Manufacturing

This is the third in a series of blogs where we discuss the requirement for detailed manufacturing engineering and manufacturing operations orchestration in the industry today and the potential benefits that can be realized by utilizing Digital Manufacturing solutions.

This post focuses on the formulated product industries, and how an overarching digital thread helps CPG manufacturers to deal with the challenges in today’s industry environment.

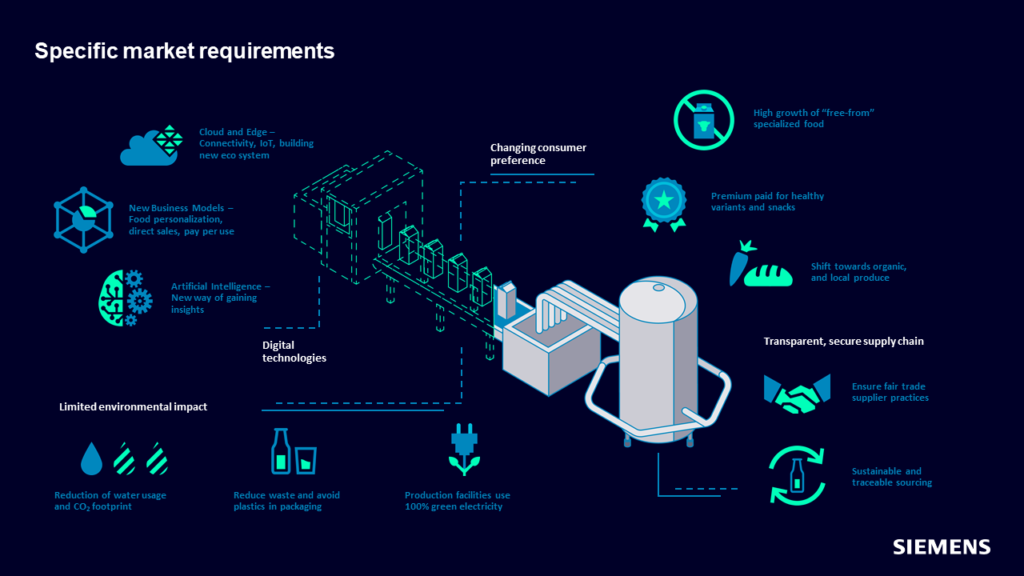

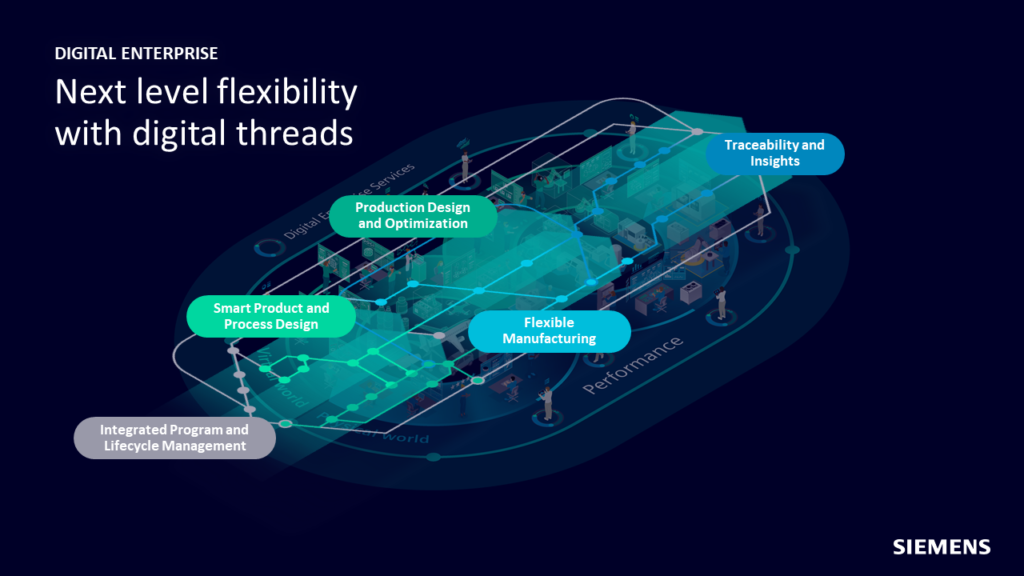

Siemens Digital Industries Software helps CPG manufacturers react quickly to demanding market requirements with a new level of flexibility, scale and speed. Digital manufacturing is crucial for responding to customer demands and increasing consumer loyalty.

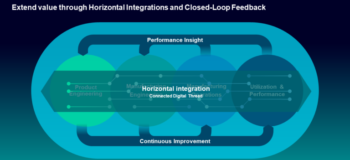

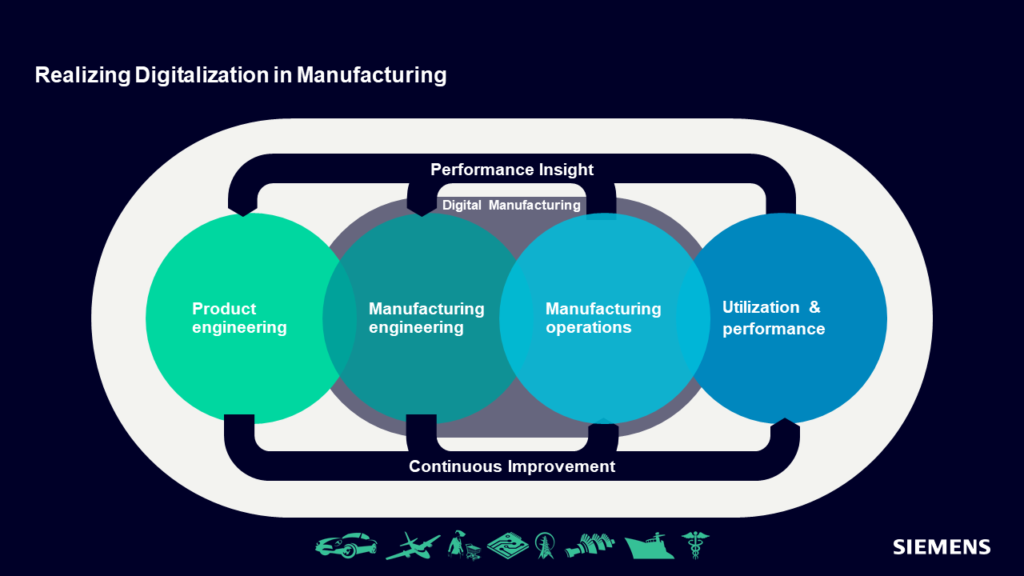

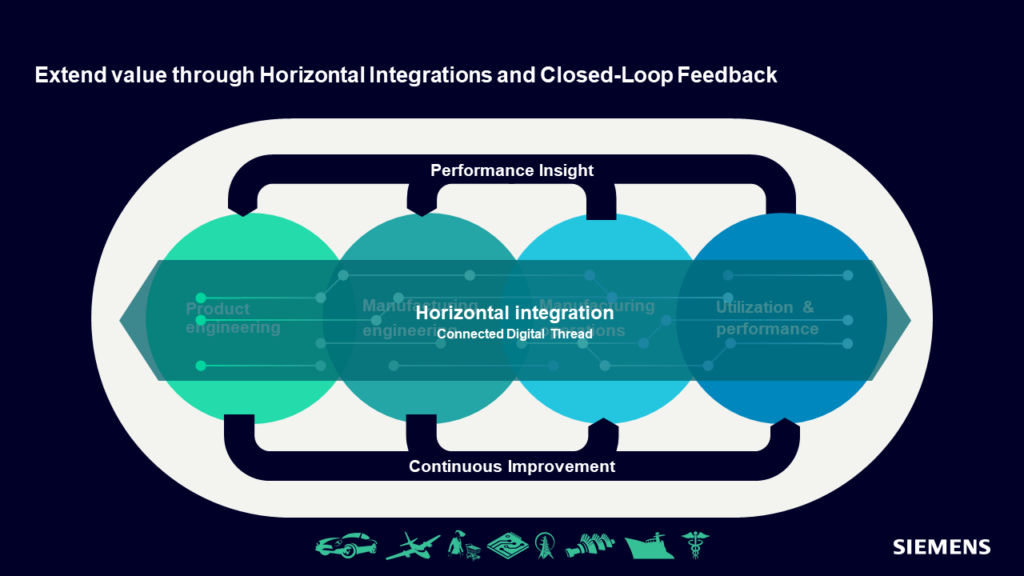

As introduced in the first blog and second blog in the series, digital manufacturing underpins the union of manufacturing engineering and manufacturing operations and is the basis for digital continuity between innovative product designs and best-in-class performance.

It was illustrated how additional value is realized by sharing information horizontally between vertically integrated manufacturing engineering and manufacturing operations capabilities – as well as other domains.

Barriers between silos are effectively removed, supporting a seamless flow of information throughout the product lifecycle. By leveraging experiences of current and past performance through closed-loop feedback, and continuity of the digital thread, designs and processes can be improved. These concepts are also of paramount importance for CPG industry manufacturers.

In the CPG industry, changing consumer demands and interests are driving many CPG manufacturers away from bulk manufacturing towards smaller and smaller production runs. Called “batch of one” or “lot size one”, the trend towards personalized products is propelling these manufacturers toward a formulated product version of Closed Loop Manufacturing. The growing consumer demands complement a common business goal among CPG manufacturers: In addition to lowering the cost of operations, these producers also want to increase revenue that a given volume of product generates. Custom, personalized, specialty and premium products help companies accomplish this goal because smaller specific batches often generate higher margins than bulk manufacturing. These smaller runs give companies an opportunity to differentiate their products from the competition and offer more variety to the consumer. With 70 percent of millennials surveyed indicating that they would switch to a more expensive product if it meant getting better quality,[1] the market for these small-batch products is open.

Consider, for example, the difference in profit margin for a candy maker, which in one instance makes a single large batch, and in the other instance makes multiple smaller batches — each with a modified formulation or wrapped in a specific sports team’s colors. For virtually the same production costs, the manufacturer can charge a premium price for the smaller batches — assuming the company’s manufacturing system is able to orchestrate multiple batch production without significant added cost.

Ironically, catering to the specific tastes of each consumer further raises consumer expectations of customization or personalization. This is also leading to volatility in consumer tastes and requirements that CPG manufacturers must address with both creativity and speed. In fact, development cycles for new specialized products have dropped from 4 to 6 months to as little as four weeks, according to McKinsey. Custom or personalized products require even faster turnaround, best accommodated by manufacturing flexibility and reconfigurability.

The trend toward batch of one manufacturing correlates with greater possible complexity of product design or formulation. Allergen-free foods, digital aids for product application, or personal care products tailored based on individual medical information illustrate the kinds of complexity challenging the process manufacturer. The combination of small batches and quick time-to-market accelerates the tipping point for digital manufacturing systems that offer:

- Formulation simulation capabilities

- Compatibility of R&D and quality lab data and systems

- Fast and reliable mechanism to transfer R&D designs to the manufacturing plant

- Simulate ability of different plants to correctly manufacture the new formulation

- Embedded quality test operations within the manufacturing process

- Fast handling of potential recalls to limit impact and reputation damage

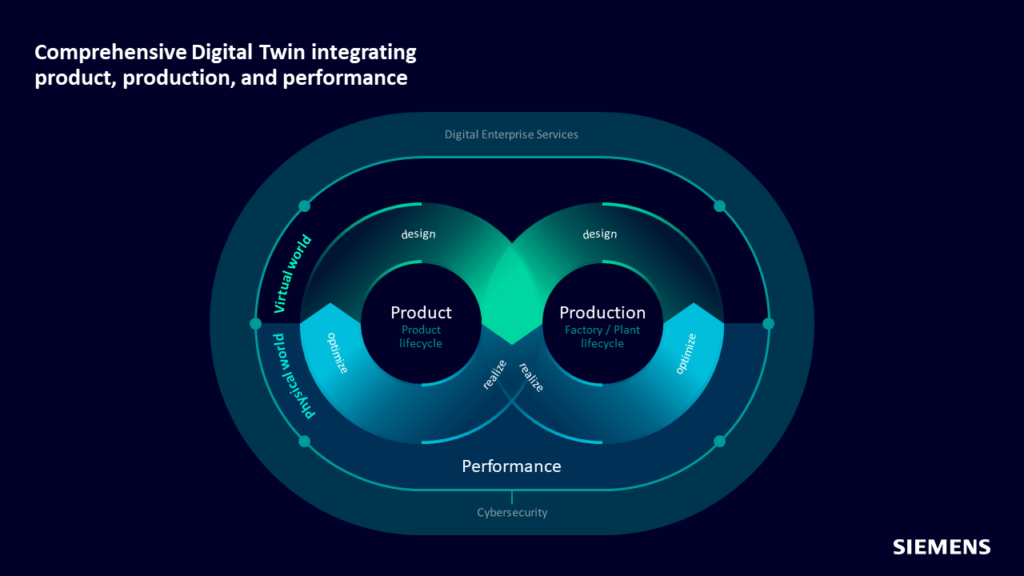

Digital twins are a critical mechanism for operating this level of closed-loop manufacturing. Digital twins provide foresight into real manufacturing using modelling and simulation of both the product and plant lifecycle.

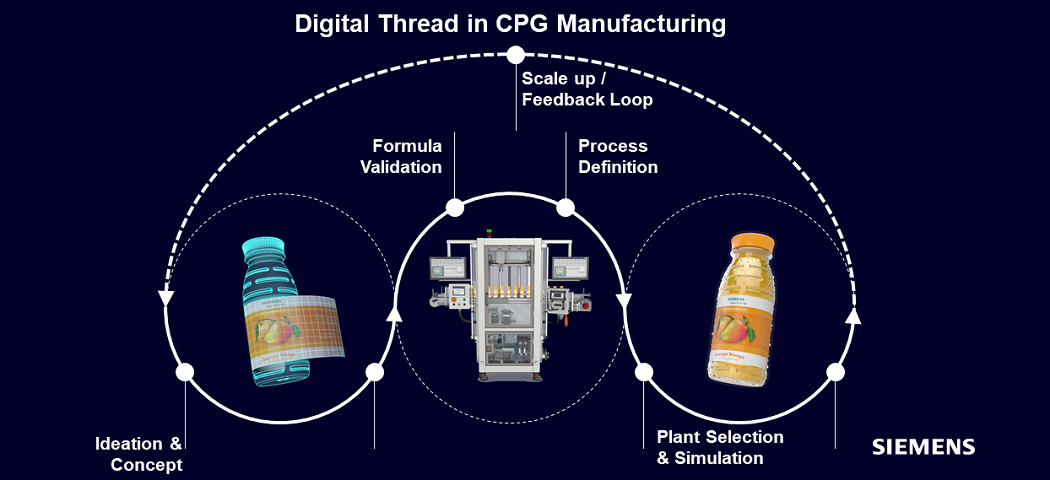

Closed-loop manufacturing (CLM) for CPG manufacturers relies strongly on digital twins, with the sources and interplay of data growing as the digital manufacturing ecosystem advances in functionality, scale and extensibility. It should be noted that in the CPG industry – where batch-based manufacturing processes occur (for example, food and beverage, specialty chemicals in home and personal care) and the bill of material (BOM) is a formula specification – the focus of CLM is on formulation and its general recipe first, then on a further definition and refinement of the formulation and general recipe towards a plant-specific BoM and an executable bill of process (BOP) that takes into account the local plant model and environmental conditions. As such, the digital thread enables to translate the original R&D product recipe into an executable production recipe.

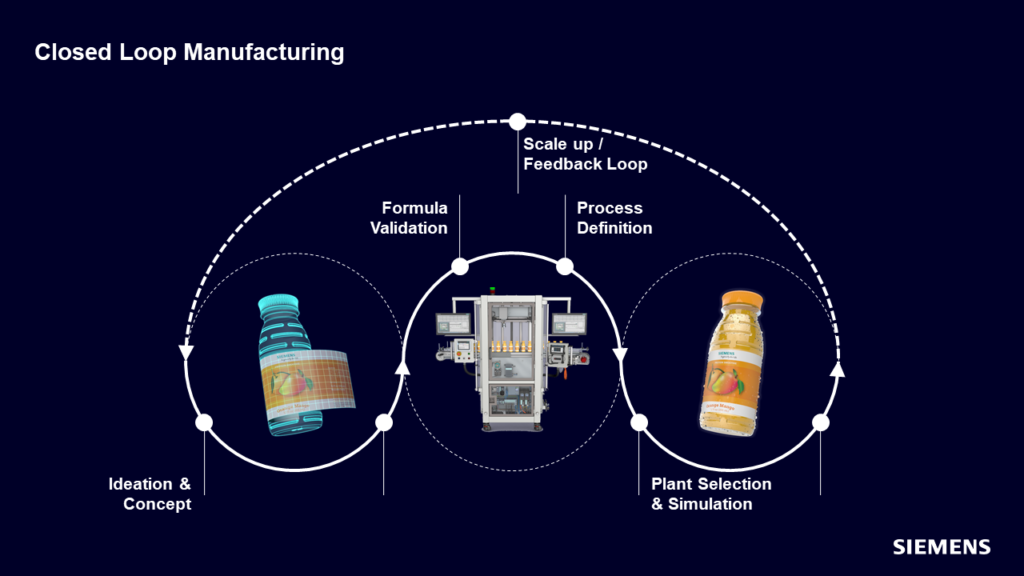

Applying CLM at a CPG manufacturer, a new product introduction may involve the following steps:

- The formulation is optimized toward targets (defined in a project brief) by using the digital twin of a product.

- Product simulations, lab experiments and pilot batches (instead of material/component testing and prototyping) provides insights into target parameters and quality.

- Results of formulation pilot batches/testing help determine what plant/production line is best suited to the manufacture of that product.

- Manufacturing simulations based on the digital twin of production are conducted to determine if production changes (new equipment) might improve the formulated product manufacturing process and/or save time and energy.

Especially distinct from discrete manufacturing is the upscaling process in CPG/Process industries. In advancing from laboratory to standard plant scale, both the formula and the operational steps and parameters are fine-tuned to be suitable for production on a large scale. For example, chemical reaction processes differ in small versus large quantities or vessels, and the digital manufacturing system must account for these differences. Likewise, product and process features and parameters potentially need to be adjusted in order to manufacture the product at a large scale in a mainstream manufacturing plant.

In more advanced Digital Enterprise deployments, the digital twin provides deeper insight by incorporating real-world performance as well as more comprehensive supplier data. Product packaging may feature public traceability through quick response (QR) codes. The IoT and mechanisms like Blockchain provide information about the source of raw materials, how and where the batch was processed, batch-specific processing parameters, and so on. The digital twin of performance enables further optimizations starting from the formula. For example, a manufacturer may be able to predict a product’s shelf life based on the product formulation.

Ultimately, batch of one manufacturing will service the growing trend away from brick and mortar and toward digital sales. Younger consumers want to directly order exactly what they like, instead of going to a retail location and choosing among multiple varieties. This trend also raises the specter of global competition for products that once enjoyed a location-based edge on competing products.

Siemens digital manufacturing software capabilities enhance CPG manufacturers’ ability to respond promptly to market demands and better connect to consumers. In terms of manufacturing agility and flexibility, it provides clear benefits:

- 2x faster product introduction to reduce time to market

- Best use of existing machines and flexible adjustments to new requirements

- Error reduction when introducing new products, technologies and processes thanks to scenario simulation in existing digital twin

- Optimized product shifts for smaller batches without negative effect on total production volume

- Full transparency about resources and product genealogy

If you are intrigued by this blog and want to know more about our offering please have a look at this explanation of our Digital Enterprise for the CPG industry based on a real example.

Siemens, with its Xcelerator™ portfolio of Digital Manufacturing and Manufacturing Operations Management software, is helping manufacturers connect and enrich the digital thread from design to execution and beyond. This not only helps to relieve the pressures of today but also helps to establish the required foundation for tomorrow.

[1] Label Insight, How Consumer Demand for Transparency is Shaping the Food Industry, 2016.