What’s New in NX for Manufacturing (June 2020) [VIDEO]

We are excited to announce the latest version of NX for Manufacturing, our comprehensive software suite that automates and connects end-to-end production processes, accelerating part manufacturing.

The new capabilities in NX enable faster CNC programming, higher machining efficiency, and streamlined 3D printing job preparation. The enhanced CMM inspection programming tools further automate the creation of inspection paths for improved part quality.

Read more about the new features in NX for Manufacturing below.

NX CAM

NX CAM software provides advanced CNC programming capabilities for a wide range of jobs – from 2.5-axis milling and turning to high-speed machining and multi-axis milling and robotic operations.

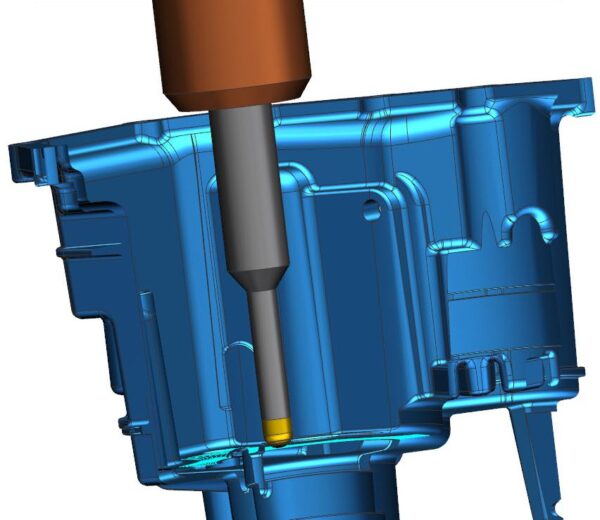

Report Shortest tool streamlines programming of parts with deep features, ensuring collision-free milling operations. It helps you use shorter tools to minimize tool deflections resulting in more stable machining and improved surface quality.

Watch this short demonstration video to see how you can use the Report Shortest Tool capability to quickly create efficient milling operations using tools with optimal length.

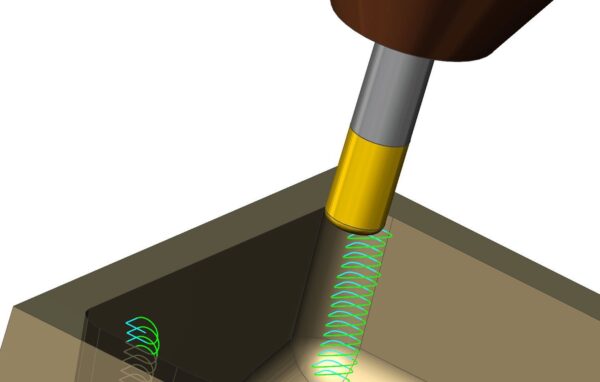

Smooth Transitions helps you generate optimized, smooth transitions between rest milling’s cutting passes, enabling use of higher feedrates and improved machining conditions, reducing machining time.

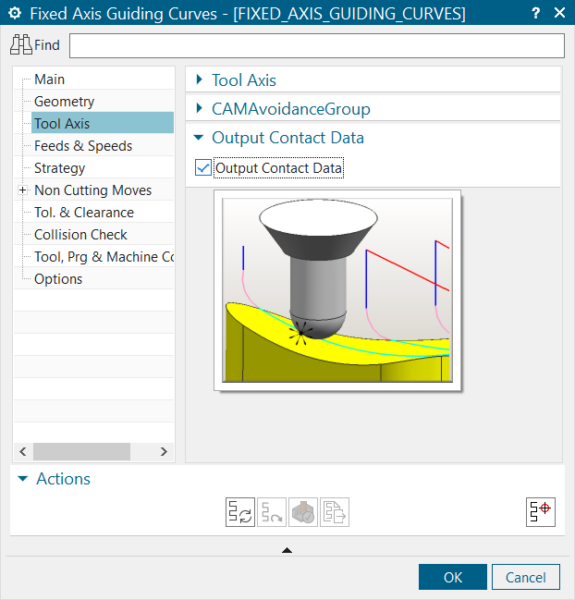

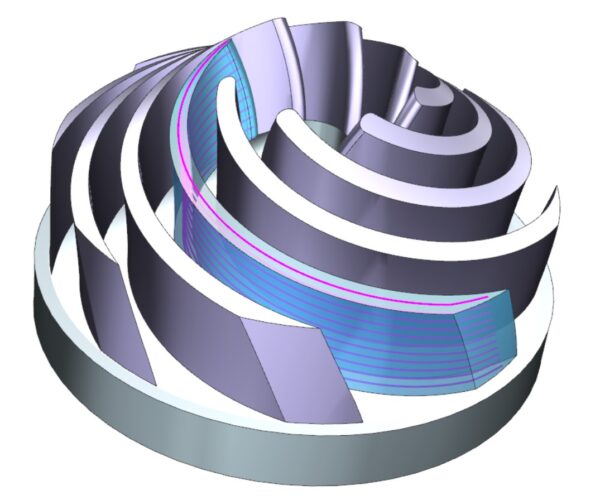

The 3-axis Guiding Curves, an advanced finishing method, can now calculate toolpaths with contact points significantly faster, shortening the programming time of complex parts.

NX Additive Manufacturing

NX Additive Manufacturing software offers comprehensive capabilities, from design to print to post-print validation, in a single integrated system.

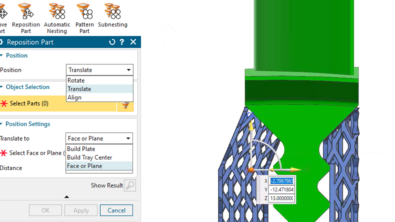

Copy / Paste of Parts and Supports enables quick positioning of multiple parts with their support structures in the build tray.

Additive Multi-Track Buildup is a new operation that streamlines the programming of multi-axis parts with near constant wall thickness. By using a constant number of additive beads, this new capability ensures a consistent thickness and height.

Apply Rules enables defined events to be inserted into a multi-axis additive operation based on time or distance. This allows for different multi-axis additive technologies to insert rules or commands specific to their unique requirements.

Tilt Tool Axis on Finish Passes allows for proven NX multi-axis functionality to control the 5-axis movement of finish paths within operations. This allows for complete collision checking, as well as smooth multi-axis output, allowing for a higher quality output on the additive machine.

NX CMM Inspection Programming

NX CMM Inspection Programming software provides advanced capabilities that helps you automate programming, while using the latest inspection methods.

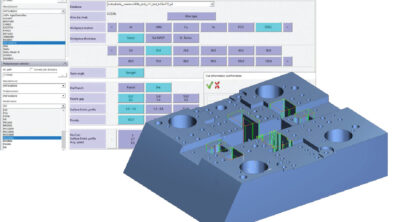

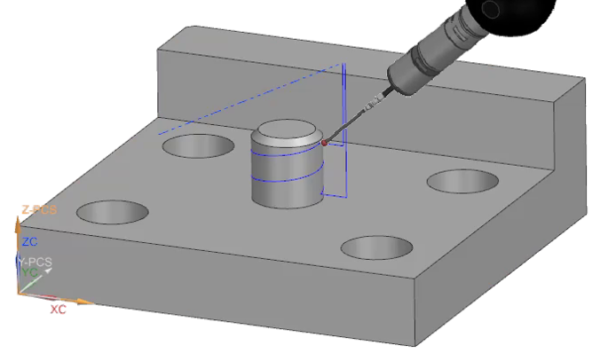

Boundary scan curve on plane automatically generates inspection paths for tactile scanning, enabling faster and more accurate part inspection. By eliminating geometry creation, such as those used by traditional CMM inspection systems, it standardizes the process and speeds up inspection programming.

Path order optimization helps you output the most time efficient inspection program with a single click. It optimizes the program for probe changes, head angles, and it minimizes the distance between paths.

For a quick review of the new capabilities in the previous releases of NX for Manufacturing, you can click the Product Updates topic below.

And to learn about the new design tools in NX, please visit the Latest NX Update: Breaking down the barriers to innovation blog post.

Additional resources for manufacturers

You can discover the full power of NX CAM by launching the free NX CAM cloud trial in your internet browser.

Watch this short video to learn about NX CAM Cloud Connected products, our flexible subscription-based software available from the Siemens Online Store.

Join the discussion with peers and industry experts on the online NX Manufacturing Community, and stay up to date by visiting the NX Manufacturing Blog.

To learn more about the comprehensive solutions for part manufacturing from Siemens Digital Industries Software, please visit our NX for Manufacturing website.