Saving the planet, one simulation at a time

Can a simulation save the planet? One simulation is not enough. But one simulation with that intent can inspire other engineers and researchers to do the same. This butterfly effect is happening today in turbine design.

Sweden’s electricity comes mainly from Hydropower and Nuclear power. This has been the case for a long time. But lately a lot of focus has still been on building wind and solar plants. Here in Sweden we also have more trees being grown than being cut down. We are close to being carbon negative, transportation and industry included.

With this country-wide energy focus friends often ask me why I work with gas turbines. Surely, they are not needed? I rarely get them to listen to my answer for more than a few minutes, as it quickly goes technical! But to put it short – I do it to save the planet. Or rather, we do it to save the planet. Because I am not alone in this effort. Many people work on making turbines run more efficiently, with fewer – or even no – polluting emissions. We can’t do everything by ourselves, but our work can inspire others and together we can create a clean every future.

My small part in this plan is to make sure the actual makers of gas turbines have the best tools in the world for designing new and better electricity generating or flight enabling propulsion products. In this blog I take a look at the many ways turbine companies are using our simulation tools to do just that.

The butterfly effect

A researcher or an engineer lives and breathes the very essence of standing on the shoulder of giants. Very few will become the new Albert Einstein, Nikola Tesla or Werner von Siemens. Every engineer does their small part, working to understand what other have done before, then improve on that or redesign it from the ground. But each of those individual contributions add up to huge technical progress. You can see this butterfly effect in the articles in the latest edition of engineer innovation: different engineers, using simulation in different ways, but with one clear aim: improving turbine and power generation performance

Take simulation to the next level

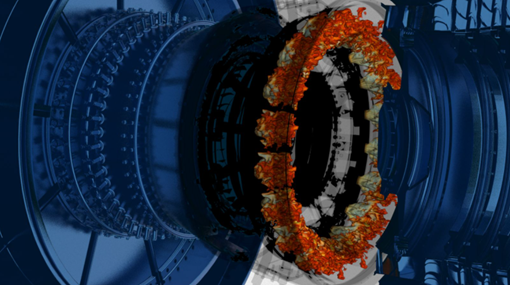

To have the most efficient and reliable turbines you always have to utilize the most efficient software for design and simulation. Siemens Energy are now taking their use of Simcenter STAR-CCM+ to the next level, by combining combustion and turbine simulations for more accurate temperature predictions which allows you to increase the efficiency by lowering cooling air consumption in the end. This is an extension of what was done earlier in the combustion team as previously shown in the engineer innovation issue. For an overview of their latest works, watch the high fidelity aerodynamics webinar presentation. One engineer can do more, a team pushes the limits.

Burning a new fuel

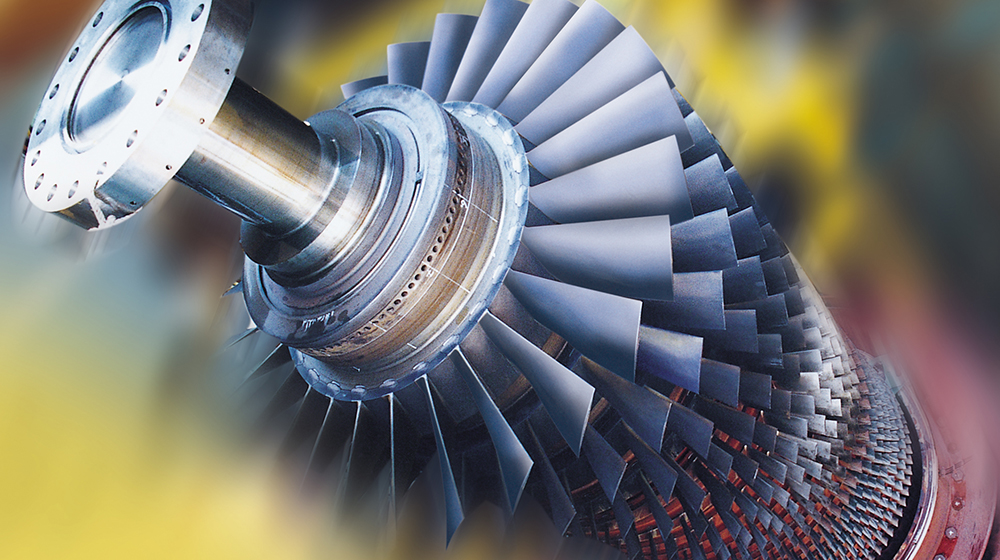

A gas turbine is a thermodynamic masterpiece. Due to the high power output and thermal efficiency, it is one of the most compact way of generating either electricity or propulsion. It can also be made light, why the gas turbine engine is enabling people to fly. It is also widely popular for heat and power production on the ground.

The two major emissions from a gas turbine is H2O and CO2. But does a gas turbine have to run on natural gas? Watch this webinar from B&B Agema on how they used simulation as part of designing the world’s first gas turbine to run on pure hydrogen. Which means the only emission will be water. Simcenter STAR-CCM+ has capabilities which makes it the safest, fastest, most accurate way of predicting how new fuels will behave and how it will affect the combustion chamber and turbine.

Listen to the experts at conferences

One of the largest conferences each year is ASME IGTI Turboexpo. That is where most of the experts connected to gas turbines and aero engines present the latest when it comes to turbine development. A lot of research now goes towards making hydrogen work for aero engines as well, which is really exciting. One of the best papers from Siemens this year was: Investigation of adaptive mesh refinement on an industrial gas turbine combustor by Liam McManus et al. This was also accepted by the Journal of Engineering for Gas Turbines and Power.

Listen to the experts at Siemens DISW

And of course, we should not forget the experts we have in Siemens Digital Industries software. Keep an eye on the blog for regular updates from our industry specialists. For further reading in case you have missed them:

The sound of hydrogen combustion CFD – Simcenter (Siemens.com) by Liam McManus

The Art of Turbomachinery by Justin Hodges

Enjoy tuning your simulations? Look away! By Chad Custer

Better design decisions for your CFD simulations with surrogate models – Simcenter (Siemens.com) by Bahaa Haddoukessouni

Multi-stage cyclic symmetry in rotor dynamics – Simcenter (Siemens.com) by Caroline Raick

This was a short contemplation of what has happened over the last year. But if we look at the bigger picture, these are just a small sample size of all heroes working together to make efficient gas turbines, cleaner, greener, safer and more reliable than ever before. One idea, one engineer, one simulation, starts it off. Sets it in motion. It quickly grows to 100s and 1000s.