4 reasons AUTOSAR integration is faster, smarter, connected with Siemens Capital Embedded Integrator

How can Siemens Capital Embedded Integrator streamlines AUTOSAR Classic Platform integration?

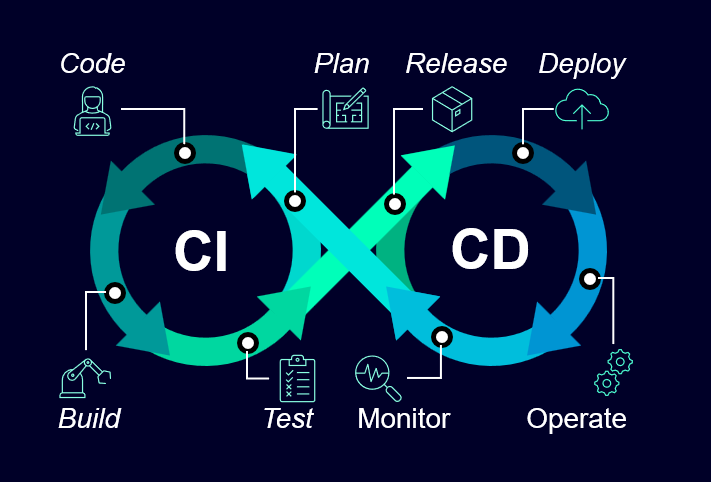

As vehicles become increasingly software-defined, the pressure on engineering teams to move faster while maintaining traceability, compliance, and quality is higher than ever. Nowhere is this more apparent than in the integration of AUTOSAR-based embedded software systems. With growing demand for continuous integration/continuous delivery (CI/CD), more variation across product lines, and increasingly complex electrical/electronic (E/E) architectures, the old way of working using manual imports, disconnected teams, and last-minute testing is inadequate – and risky.

Instead, leading teams are shifting to a connected, automated integration approach that embeds traceability, accelerates delivery, and supports continuous validation from day one. By rethinking how basic software is configured and tested, they’re gaining the speed and confidence needed to deliver complex features at scale.

In a recent webinar, Mathias Fritzson, Siemens Digital Industries Software; Chintu Parikh, Presales Solutions Consultant Siemens Digital Industries Software; and Lance Brooks, Principal Engineer of Siemens Digital Industries Software showcased how the Capital Embedded Integrator streamlines AUTOSAR Classic Platform integration – from software architecture through software configuration and virtual validation.

This blog post provides high-level takeaways, including 4 reasons why AUTOSAR integration is faster, smarter, and connected with Siemens Capital Embedded Integrator.

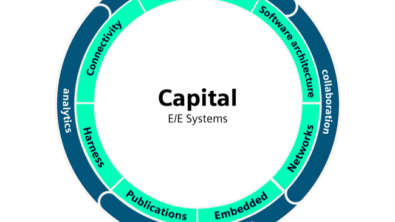

1) Siemens Capital Embedded is built for modern AUTOSAR integration

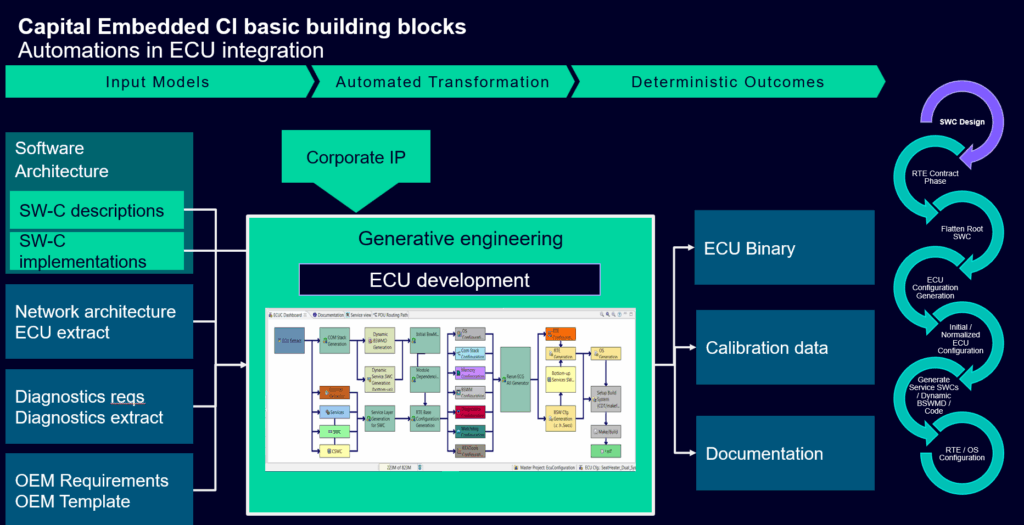

Traditional ECU integration workflows are often bogged down by siloed tools, manual rework, and unclear requirements traceability. Capital Embedded Integrator addresses these challenges by delivering an end-to-end toolchain designed for speed, accuracy, and traceability.

The solution automates up to 90% of basic software configuration and enables linking parameters directly to Polarion requirements, ensuring end-to-end traceability. It also provides guided workflows that are up to 5X faster than traditional, unguided approaches, reducing manual effort and minimizing errors.

Capital Embedded Integrator imports all key artifacts such as ECU Extract, system description, diagnostic extracts, and MCAL configuration in the AUTOSAR XML format (ARXML), but also many legacy data formats if required. The direct import of these configurations using them to generate the ECU configuration, helps to maintain momentum and accuracy when working across complex, multi-source environments.

To further improve reliability, Capital Embedded Integrator includes built-in consistency checks that help ensure configurations are correct by design. The tool also includes smart editors for mapping software components to cores, task scheduling, and code partitioning, enabling precise control without tedious manual work.

2) A CI/CD-Ready Foundation

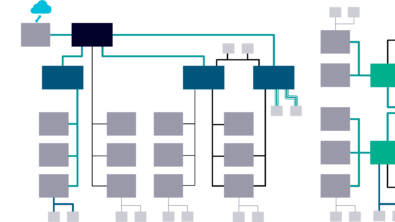

Capital Embedded Integrator supports both Windows and Linux environments. It’s also designed for integration with common CI/CD infrastructure, including Git, Jenkins, and cloud-based build systems. This means you can automate imports, configuration, and code generation with simple scripts, and easily create pipelines for continuous builds and validations.

Integrators can trigger Jenkins builds directly from the Integrator tool, generate consistent outputs, and run automated checks to ensure every build meets design intent. These capabilities make it feasible to run full build cycles overnight or even per commit – a process that typically requires days of lab time.

A key differentiator is that automation flows can be reused across teams and projects, ensuring consistency and accelerating onboarding for new developers or programs.

3) Traceability That Goes Beyond Compliance

Linking basic software (BSW) configuration to requirements is a practical necessity when changes are constant and multiple teams have to collaborate to make them happen. Using Capital Embedded’s Polarion integration, you can establish bidirectional links between requirements and configuration elements, and instantly identify which features need to be reconfigured after a revision. It’s also much easier to confirm that no safety or compliance-critical features were missed.

During the webinar, Chintu demonstrated how in one scenario, Polarion’s embedded browser was used to select system signals and link them to AUTOSAR objects directly within the tool, without the need for a separate instance. This resulted in a 7X improvement in traceability efficiency compared to traditional, disconnected methods.

4) Siemens Capital Embedded bring a seamless integration-to-verification process

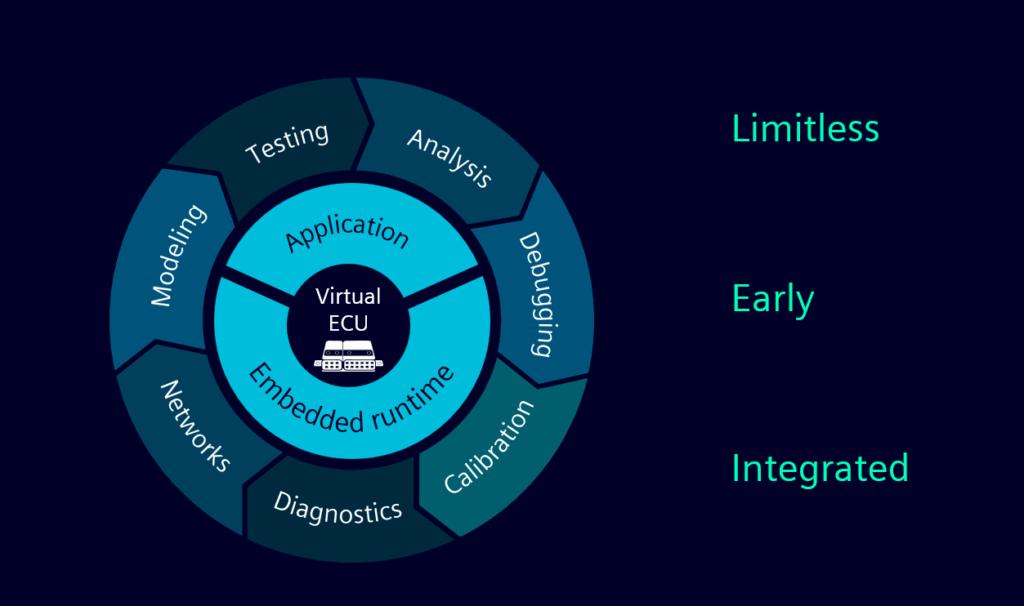

In the final portion of the webinar, Lance Brooks introduced Siemens’ virtual ECU (vECU) environment, which enables continuous verification and collaboration across distributed teams.

By deploying virtual ECUs on developers’ desktops, teams can:

- Test and debug in the same environment where the code is developed

- Pause, step through, and observe ECU behavior during test scenarios

- Reuse tests across model-based, code-level, and lab-level validation

- Share complete test environments digitally without a test bench

The vECU approach dramatically reduces bottlenecks and reproduces errors found in the lab quickly avoiding the back-and-forth between test teams and developers that traditionally delays releases. The same tests can also be used in HiL environments, ensuring maximum reuse and minimal duplication.

AUTOSAR Integration, Reimagined

The capabilities demonstrated during the webinar should be used to introduce a fundamental shift in AUTOSAR integration from slow, manual, error-prone processes to connected, intelligent workflows that scale. The impact is significant: Siemens reports that Capital Embedded Integrator reduces manual effort by up to 70%, with scripting and traceability features improving efficiency by up to 7X over disconnected environments.

By unifying integration and validation into a continuous, automated workflow, engineering teams can drastically reduce delays, eliminate rework, and accelerate time-to-market – all while maintaining compliance and system-level traceability.

Watch the full webinar now to see live demonstrations of these capabilities and how Siemens can help you future-proof embedded software development with Capital Embedded.