Q&A with Mathias Fritzson: Solving challenges in battery management systems and BMS development

Battery Management Systems (BMS) are pivotal in ensuring the safety, efficiency and longevity of modern electric vehicles (EVs). Yet, developing a BMS has become increasingly complex. In this blog post, Mathias Fritzson, Product Manager for Siemens Capital Embedded software products, shares valuable insights into the evolving challenges of BMS development, and explains how new tools and methodologies can simplify the process, reduce defects and accelerate innovation.

Q: Why has BMS development become so complex in recent years?

Mathias Fritzson: The rise of electric vehicles has brought unprecedented demands for battery performance, safety and cost-effectiveness. Batteries are no longer simple systems. They now involve intricate electrical, chemical and thermal dynamics, all of which must be optimized simultaneously. Each battery cell chemistry has its own trade-offs between energy density, manufacturability and safety, requiring multiple iterations to find the right balance.

Not only that – a battery’s design must integrate seamlessly with the overall vehicle architecture. Its performance impacts – and is impacted – by other systems such as power electronics and thermal management. Traditional methods that rely heavily on physical prototypes and manual processes are simply too slow and expensive for today’s fast-paced market.

Q: What trends are shaping how BMS are developed today?

MF: There are many. First, the growing focus on sustainability and EV adoption is increasing pressure on manufacturers to innovate faster and more cost-effectively. At the same time, the industry is shifting towards digital – simulation, digital twins, and integrated design tools will help to streamline development.

Modularity is also a trend. BMSs are becoming more software-defined, meaning you need robust platforms to handle complex algorithms and multicore processing. This is where tools based on standards like AUTOSAR come into play, providing a standardized platform for embedded software integration.

Finally, there’s an increasing emphasis on ensuring cybersecurity and functional safety. As vehicles become more connected, the risks associated with software vulnerabilities grow, making compliance with standards like ISO 26262, ISO/SAE 21434 and robust risk management essential.

Q: How does Siemens address the challenges of modern BMS development?

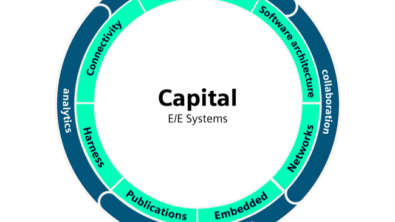

MF: At Siemens, we take a holistic approach to BMS development. Our digital thread connects every stage of the design process, from initial concept, to validation and deployment. We make it easier for teams to collaborate seamlessly, at every stage of the development process and across functional areas.

For example, Siemens SimCenter provides multi-physics simulations to test and validate battery performance across thermal, electrical and structural domains. Engineers can explore design variants early in the development process, without having to build costly physical prototypes.

We also integrate with software development tools like Polarion for workflow management, and Capital Embedded Software for creating robust, scalable embedded systems. Together, these tools ensure that embedded software is aligned with hardware systems from the start, creating a seamless and concurrent engineering flow that accelerates development and, ultimately, improves product quality.

Q: Can you explain the role of simulation and the digital twin?

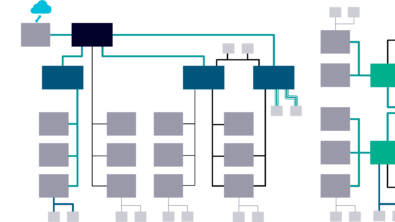

MF: A digital twin is essentially a virtual representation of e.g. a battery or a full vehicle system. It captures the system’s behavior under various conditions. Using tools like SimCenter, you can test different scenarios, which would be difficult to do in real life. For example, you can test the product’s performance under extreme temperature changes or rapid charge and discharge cycles.

Simulations like these accelerate the design cycle by helping you identify potential issues early. Plus, they enable more comprehensive validation – you can simulate how a BMS algorithm responds to different battery chemistries or thermal dynamics before moving to hardware testing. Other side benefits include lower development costs and reduced environmental impact.

Q: How does Siemens tackle embedded software development for BMS?

MF: The challenge with embedded software is to ensure seamless integration with hardware while meeting performance, safety and cybersecurity requirements. At Siemens, we use Capital Embedded Software to provide an AUTOSAR based platform to accomplish these goals.

Capital enables the development of modular software application architectures and configurable application interfaces, to simplify integrations. We enable the seamless use of a combination of model-in-the-loop, software-in-the-loop, and virtual hardware-in-the-loop testing, as well, so teams can validate software performance at every stage of development to minimize the chance of defects.

Q: Can you summarize why teams should choose Siemens for battery management, software development, and validation?

MF: Siemens solutions help teams work faster and more efficiently to produce defect-free outcomes. Our end-to-end connected workflow integrates requirements seamlessly across the entire development chain, from models and simulations to embedded software implementation, integration and validation.

With built-in support for functional safety and cybersecurity, our platform ensures compliance and reliability at every stage, and when teams apply their expertise in batteries and algorithms using Siemens’ tools, they can streamline processes, reduce time-to-market, and deliver high-quality battery management software faster than ever.

Go further

Watch the webinar, “Developing defect-free and secure battery management systems” to learn more about how Siemens is driving innovation in BMS development.