Optimizing heavy equipment maintenance and service with digital transformation

The heavy equipment industry typically works in low volume production, with a number of reasons for this. For one, heavy equipment products are quite complex and specialized for very specific applications, so there is not much need to produce them in the same numbers as the automotive industry, for example. Additionally, many heavy equipment products have long lifespans in the field. Customers tend to extend the use of their machines on hand rather than buy new ones, especially when it is the more economically viable option.

As such, some original equipment manufacturers (OEMs) for heavy equipment are looking to invest in maintenance and service for the products they create to increase profits. Such management across the product lifecycle, however, can involve large amounts of data and documentation that can be difficult to manage. Fortunately, there are multiple tools and solutions and tools OEMs can find as they invest in their digital transformation journeys, including but not limited to the comprehensive digital twin, IoT sensors, and artificial intelligence (AI).

The core of digital transformation

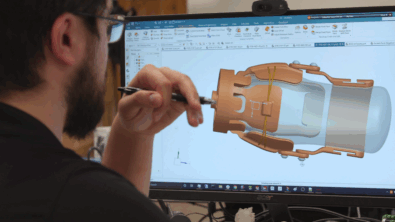

Any investment into digital transformation requires a strong foundation, and that foundation is the comprehensive digital twin. As the virtual representation of a product, the comprehensive digital twin provides end-to-end, real-time data connectivity between all stakeholders of the product across its lifecycle. This covers everything from the earliest stages of design, production, and even active operation.

With the comprehensive digital twin, heavy equipment OEMs can ensure all the information they maintain on their equipment is constantly up to date. The kinds of data it can incorporate includes software updates, customizations, retrofits, previous service, basically the product’s entire history. Having all this accurate, real-time information in the digital twin helps ensure whatever service is being done to the product whenever it is brought in is performed as best as it can be.

Acquiring the data

Of course, proper infrastructure needs to be in place for the digital twin to receive said information from across the product lifecycle, especially when the product is in the field. This is where the Internet of Things (IoT) comes into play. OEMs can integrate IoT sensors onto their physical process, which can continually monitor the products in real-time and constantly send data about its current conditions back to OEMs for analysis.

OEMs can use the data collected by IoT sensors in variety of ways. Perhaps most pertinent to the subject of service and maintenance, OEMs can analyze where and how often their products degrade. This data can then be used to establish predictive maintenance schedules that align with degradation rates, optimizing how long they are in the field working while keeping their lifespans extended for as long as possible. In another use case, the same data can be utilized by OEMs to optimize the designs and functions of new products, as well as retrofitting old ones.

Managing the future with AI

As might be estimated, such methodologies will likely result in the generation and transference of enormous amounts of data. This can be cumbersome on its own, but the service ecosystems OEMs create are bound to involve multiple parties with many different IT systems. Sharing information across them all will likely be a challenging task, and collating that data into actionable insights may be even more challenging.

While AI is still a developing technology, one of its emerging strengths is its ability to go through immense quantities of data in record times and offer answers to prompted questions. With the right amount of investment, heavy equipment OEMs can explore ways they can integrate AI into their service methodologies and leverage all the data they accumulate to help their engineers find the right answers faster.

A digitalized future

Heavy equipment OEMs’ journeys into product maintenance and service will certainly raise new questions to solve, but one thing for certain is that data will be at the center of them all. Digital transformation and all the technologies it provides are just the thing to collect, share, and leverage that data to bring about a new era of optimized products and services that can benefit OEMs and the customers they serve.

Siemens Digital Industries Software helps organizations of all sizes digitally transform using software, hardware and services from the Siemens Xcelerator business platform. Siemens’ software and the comprehensive digital twin enable companies to optimize their design, engineering and manufacturing processes to turn today’s ideas into the sustainable products of the future. From chips to entire systems, from product to process, across all industries. Siemens Digital Industries Software – Accelerating transformation.