The Digital Enterprise and the Synthesis of Industrial AI, Digital Twin and Data

The industrial world is changing. The need for speed and adaptability is higher than ever as products and industrial systems grow in complexity to meet more rigorous customer demands. Companies need to change how they design and produce products, gather data and use resources.

To overcome these challenges, companies must embrace digital transformation to combine the real and digital worlds, managing product and production lifecycles through a unified digital ecosystem. Now, through the unique synthesis of industrial software and automation in the Siemens Xcelerator portfolio, companies can build such a unified ecosystem of real and digital tools, assets and systems.

By doing so, companies can become Digital Enterprises, where everything is connected and digitalized and data and information is gathered and exchanged quickly between product and production development, testing, maintenance and operation. Critically, the seamless flow of data in a Digital Enterprise enables a holistic digital-first approach built on a single digital backbone that supports continuous optimization as insights from the real world are transferred into the digital world for analysis, driving recursive optimizations in real world processes and systems.

Digital Enterprises will develop game changing speed, adaptability, resiliency and sustainability as they collect and understand historical and real-time data. Ultimately, the effective use of data is what unlocks the full power of an organization to make fast and confident decisions based on fully digitalized workflows.

The transformation into a Digital Enterprise demands the adoption of three core technologies: the comprehensive Digital Twin, Software-Defined Everything (SDX) and Industrial Artificial Intelligence (AI). Each of these key enablers is examined below.

Foundation: Comprehensive Digital Twin

The comprehensive Digital Twin is the foundational technology, providing physics-based modeling for data in the virtual world. Through the comprehensive Digital Twin of the product and production, a modern Digital Enterprise can collect and synthesize data from throughout the product and production lifecycle. This leads to greater transparency, tracking capabilities, and the ability to create a closed loop of product development, production, and optimization.

The holistic physics-based representation of real-world objects in the virtual world enables companies to digitally plan, simulate, predict and optimize products, production processes, machines and even entire factories completely in the virtual world. The high-fidelity virtual representations enable rapid system design, simulation and testing, generating tremendous value through the evaluation of design alternatives and the prediction of future system performance. Companies can leverage these capabilities to accelerate and improve system design, supporting first time right development practices.

Connection: Software Defined Everything

Next, industries are engaging in a large-scale shift towards software-defined systems and software-driven product development and industrial automation, collectively known as Software Defined Everything (SDX). Transitioning from hardware-based solutions to software-driven development simplifies the use and development of complex systems.

Consider your own smartphone, a vastly complex device that incorporates powerful processing, wireless connectivity, various sensors and more. Despite the underlying complexity, modern smartphones are intuitive and simple to use due to carefully designed software layers that provide user interfaces that translate simple user inputs, such as a tap, into complex actions.

In an increasingly digital age, SDX will also serve as the bridge from the digital world to the products, systems and assets in the real world. Critically, live usage data is gathered from software defined systems and supplied to centralized compute and control systems. Engineers, operators or, in some cases, even end users can use this data to monitor system performance. In the other direction, programming updates can be accomplished en masse, pushing new code to multiple assets at once.

Revolution: The Age of Industrial AI

Third, artificial intelligence is expected to transform industry, ushering in a new era of industrial technology.

Yet, this transformation is just beginning, and the technology is still developing. Rapid adoption of generative AI chatbots in consumer markets has fueled excitement and speculation on the potential of the technology in industry. So far, individuals and organizations remain cautious. A recent global survey led by the University of Melbourne in collaboration with KPMG found that only 46% of respondents reported a sense of trust in AI systems (Gillespie et al., 2025).

This lack of trust is often tied to differences in risk tolerance between consumer and industrial markets. Small mistakes that can be overlooked by consumers may prove disastrous in an industrial context. Industrial leaders demand Industrial AI systems that can speak the language of engineering and manufacturing. These AI systems must prioritize precision, reliability and security while managing complexity even in highly technical environments. Industrial AI reports and suggestions must stand up to industry standards, drive scalable improvements, and preserve accessibility by all users.

Industrial AI systems will be crucial to supporting the seamless data flow that powers a Digital Enterprise. Data from various systems and teams throughout an organization will be collected, connected and contextualized to produce deeper insights and better decisions. This flow of connected data forms a unified “data fabric,” a contextual digital layer that turns multiple data streams into actionable intelligence rather than overwhelming decisionmakers with fragmented information.

Weaving a Data Fabric

Companies already produce and consume immense amounts of data during product or production development and normal operations. Industrial data can be broadly categorized into structured and unstructured data types.

The largest portion of any company’s data is typically unstructured and uncontextualized, having neither standard format nor descriptive metadata. Much of this data is contained in text, images, video files, and PDF documents that are difficult to automatically import into existing data-driven systems, such as the Digital Twin.

The Digital Twin, which is formed by connecting structured data, broad context and true-to-life simulations across many domains, is key in supporting cross-organizational data collection by creating a broader backbone for all connected data, creating a single source of truth for all teams. While the Digital Twin provides a framework for collecting, connecting and contextualizing industrial data, Industrial AI will deliver the speed and scale for companies to truly make the most of their data.

Industrial AI Accelerates Data Connection, Contextualization

The application of Industrial AI will vastly increase the speed and efficiency of connecting and contextualizing structured and unstructured data with the Digital Twin, bolstering the accuracy and completeness of the digital reflection of real-world systems. Additionally, increasingly powerful Industrial AI systems will automate the creation and management of new data streams, ensuring transparency of data workflows and automating contextualization processes.

By applying Industrial AI data processing and classification to a smart production line, the facility operator can automatically build connections and metadata between different data sources. Live sensor data from the shop floor can be combined automatically with information on material usage and production rates to produce structured and context-sensitive datasets for further analysis with the Digital Twin, uncovering new optimizations.

Knowledge graph solutions will serve a critical role in this process. Knowledge graphs provide meaning to data by connecting data points in a manner similar to human thought processes. These connections are then translated into a structure that is machine-readable and efficiently stored, retrieved and analyzed. Industrial AI systems can use these semantic models to understand the relationships between data, enabling automated connection and contextualization of distributed data sources.

One Siemens customer used a knowledge graph solution to connect and contextualize large datasets contained in a data lake. The connected and contextualized data enabled the company to perform root cause analysis quality issues that arose during production of pharmaceutical products. Information on input materials was traced throughout the production process through to the finished product, uncovering the production stages most likely to cause quality deviations. By leveraging the data available in an intelligent fashion, the company improved production efficiency by 25%, resulting in potential cost savings in the millions.

Industrial AI Supercharges Processes across Design, Realize, Optimize Lifecycle

When Industrial AI operates across the whole value chain, it delivers measurable, enterprise-wide impact. Today, Industrial AI systems are already boosting speed, accuracy, agility and efficiency from design to realization and optimization of product and production.

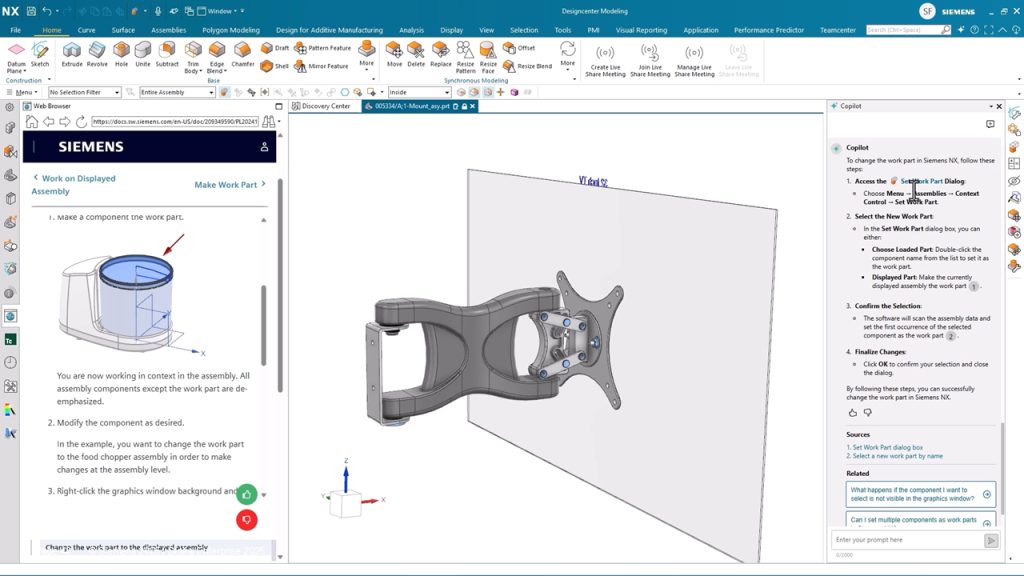

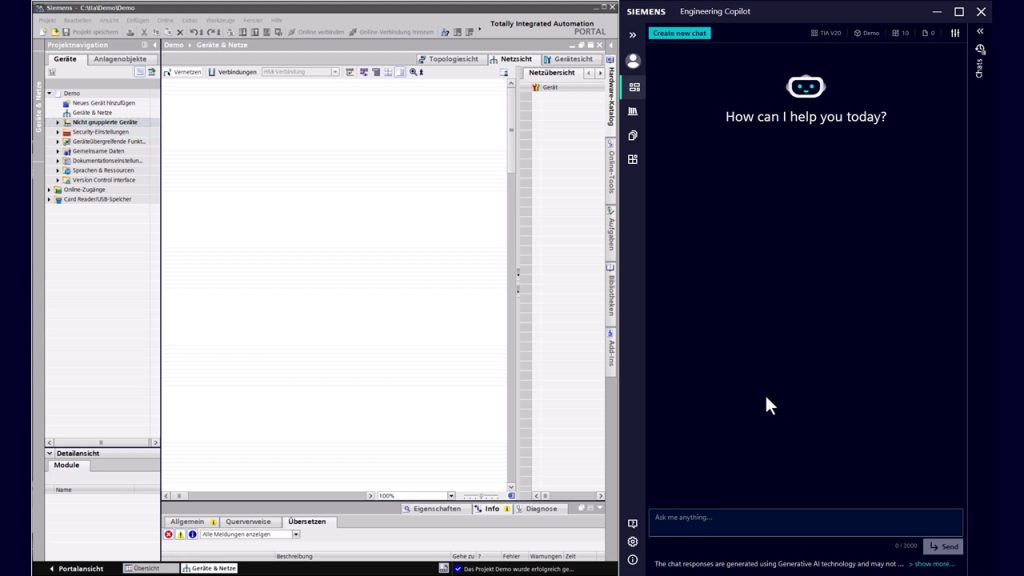

Design: Industrial Copilots Improve Efficiency

In design, Industrial AI copilots help engineers navigate complex software menus, complete tasks and learn new techniques and functions intuitively. Industrial AI enables these users to quickly find settings and functions, even those that are buried deep within menu trees. In addition, Industrial AI copilots can generate clear step-by-step instructions to guide users through executing actions, even completing some basic configuration steps automatically.

These small optimizations add up to significant time savings and a better experience at work for both new and experienced employees.

Realize: Industrial AI Simplifies Operator, Technician Workflows

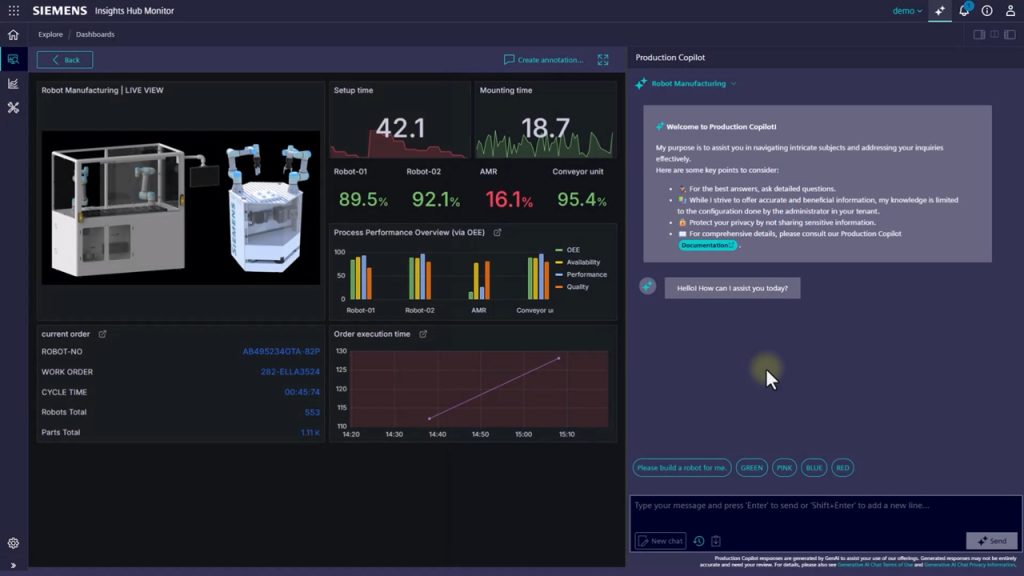

Once production begins, an Industrial AI chatbot can simplify the processing of production orders for flexible manufacturing systems that support highly customizable products. Instead of complicated menus, the operator can use a natural language chat interface to customize the product and submit an order. In response, the chatbot can supply preview images and confirm order details with the operator.

In the background, the Industrial AI system can also interface with manufacturing execution systems (MES) to check available stock and execute scripts to submit the order to the production cell. The entire order configuration and submission workflow is also built using natural language commands. The Industrial AI understands simple text statements as a set of instructions and follows them in sequence to complete the order processing workflow.

Such a workflow can be adapted to other applications. A machine builder, for instance, could build an Industrial AI assistant to support technicians in maintenance tasks, acting as an additional technical expert with direct access to machine parameters and data.

Optimize: Using Data and Industrial AI to Boost Performance

Continuous optimization is another hallmark of a Digital Enterprise. Industrial AI assistants can remove barriers to accessing critical production data, ensuring that operators have up to date information at their fingertips to improve processes or conduct more responsive maintenance.

BlueScope, a steel manufacturer and Siemens customer, has applied the Digital Twin and Industrial AI to drive process improvements and eliminate costly plant downtime. The company used the Digital Twin to create a digital “fingerprint” of each machine representing its ideal operating state. Live production data is then continuously compared to each machine fingerprint and deviations trigger alerts for operators to review the suspect data. The operators can also ask Industrial AI assistants for further information on specific assets before deciding how to address the deviation.

The Industrial AI-driven asset intelligence system employed by BlueScope enables responsive and even predictive maintenance actions based on high quality information. In many cases, the system helps detect and prevent downtime from occurring in the first place. So far, BlueScope has avoided almost 2000 hours of unplanned downtime and improved operational efficiency and sustainability.

Digital Transformation Fosters Industrial AI Adoption, Future Success

Amid vast changes in industrial markets, companies must seek out technologies and methodologies that enable speed, adaptability and sustainability. Today, many organizations are weighed down by legacy processes and disconnected solutions that silo data and hinder collaboration between teams. As products, production systems and supply chains grow in complexity these processes increasingly show their shortcomings.

Most importantly, such disjointed systems are ill-prepared for the transformation of industries in an AI-powered world. Data silos and inefficient collaboration prevent companies from making the most of organizational data and expertise. While Industrial AI can help break some of these silos, it too will be hindered by legacy processes that are not updated.

In sum, only a Digital Enterprise can harness the full power of data and Industrial AI today and in the future. Companies that take action now will lead the way into the future as they innovate more rapidly, optimize more completely and act based on deep insights.

Citation

Gillespie, N., Lockey, S., Ward, T., Macdade, A., & Hassed, G. (2025). Trust, attitudes and use of artificial intelligence: A global study 2025. The University of Melbourne and KPMG. DOI 10.26188/28822919.

Siemens Digital Industries Software helps organizations of all sizes digitally transform using software, hardware and services from the Siemens Xcelerator business platform. Siemens’ software and the comprehensive digital twin enable companies to optimize their design, engineering and manufacturing processes to turn today’s ideas into the sustainable products of the future. From chips to entire systems, from product to process, across all industries. Siemens Digital Industries Software – Accelerating transformation.