The digital revolution in battery manufacturing

In the age of modern manufacturing, few sectors are as pivotal or fast-growing as battery manufacturing. The global demand for electric vehicles is skyrocketing and the grid level energy storage demand is rising due to the worldwide shift towards renewable energy. But how can battery manufacturers keep pace with the rapidly expanding requirements of the battery industry? The answer lies in digitalization and smart manufacturing technologies.

In a recent podcast episode, Rahul Garg, VP of Industrial Machinery and the SMB Program and Puneet Sinha, Senior Director and Global Head for the Battery Industry, met to discuss the transformative journey of battery manufacturing and the role of the smart manufacturing renaissance. In this blog, we’ll share their insights by diving into battery manufacturing, exploring its evolution, challenges and the indispensable role of smart manufacturing in meeting the demands of the future.

Why is now the time for transformation?

The battery industry is far from new. Many companies, especially in the Asia-Pacific region, have been participating in battery manufacturing for over 20 years beginning with Sony’s commercialized lithium-ion batteries in 1991. However, the industry has traditionally relied on experience-driven processes. Companies have generated experts that have become incredibly familiar with their machines, equipped with the ability to discuss whether the equipment is performing as it should be or not.

But much like the science of cake-baking, where nuances in technique yield distinct outcomes, battery manufacturing demands precision and finesse. Just because 2 bakers have the same recipe, it does not mean the quality of cake will remain the same. This idea can be applied to battery manufacturing. Despite having decades of experience, duplicating battery quality will continue to be a formidable challenge, especially with increasingly complicated hurdles such as:

- Supply chain uncertainties

- Remote work

- Labor shortages

- Sustainability demands

- Increased customer communication

- Rising competition

These factors are why experience-driven manufacturing is no longer able to satisfy the demands that need to be met by the battery industry. Moreover, recent government regulations are encouraging the localization of battery manufacturing. Specifically, the Unites States is encouraging battery manufacturing onshoring due to the Inflation Reduction Act (IRA), further adding to the growing list of challenges manufacturers must face.

It is a culmination of these obstacles that has battery manufacturers in search of a contemporary solution to improve battery quality while reducing cost all while simultaneously achieving a much larger scale of battery manufacturing.

The potential of smart manufacturing

The forecast for batteries is set to reach 14 times growth from 2018 by 2030. Meaning that despite the challenges, the market for batteries presents rich opportunities for companies who are able answer the cost, quality and production equation. Companies can achieve this by learning how to leverage the data they are collecting or not currently utilizing from the factory floor to improve their processes, throughput and yield—something that wouldn’t be possible without smart manufacturing.

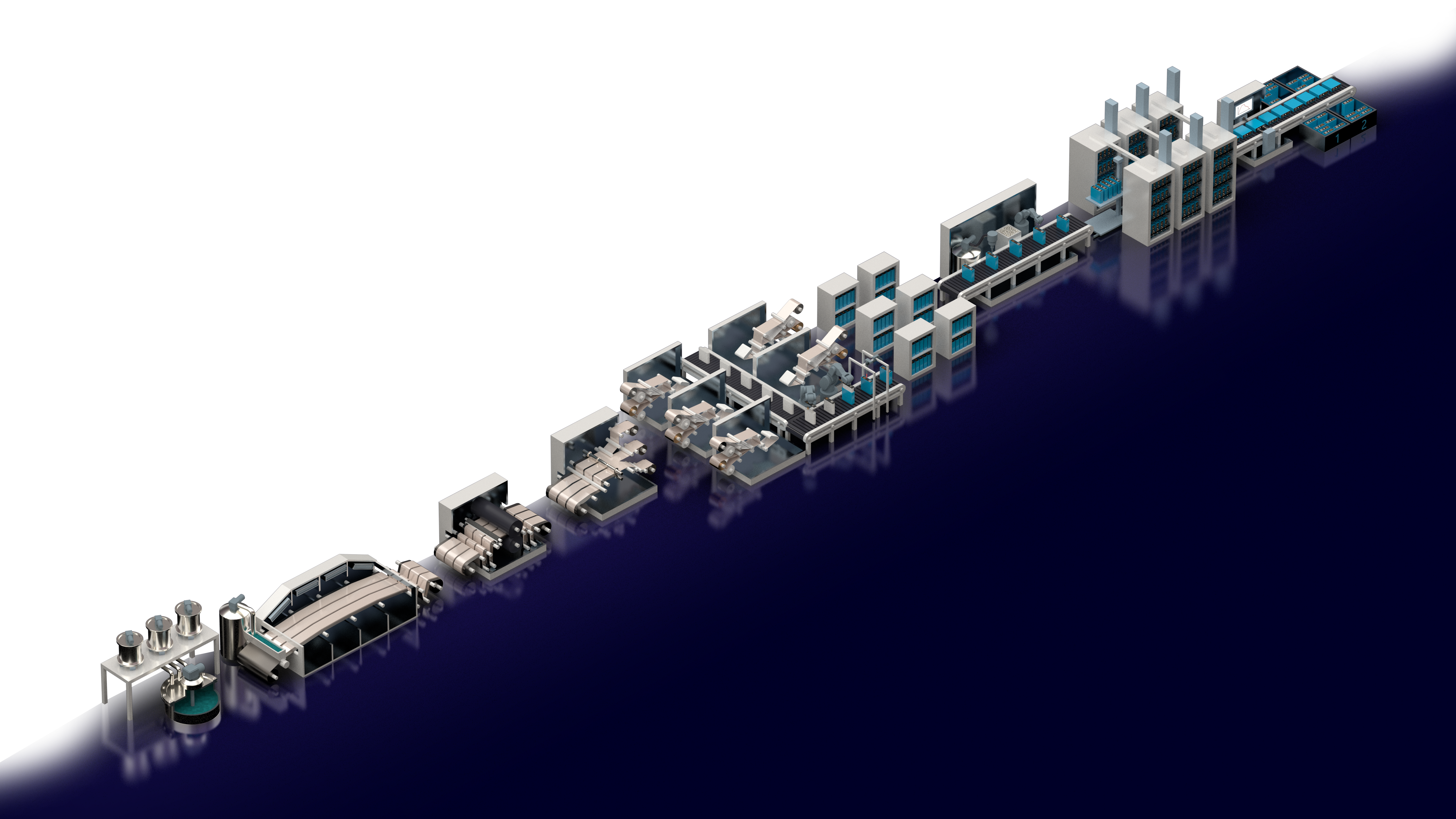

The benefits of unlocking these data silos underscores the importance of digitization in speeding up this process. Digital transformation enables the integration of the Digital Twin, automation technologies and IT/OT convergence. These digital tools facilitate the creation of closed-loop optimization where battery development, manufacturing and deployment can all be enhanced. As a result, manufacturers can reach their goals of scaling production, reducing costs and maintaining optimal quality.

In addition, it’s not just US companies welcoming these changes. Countries around the world are heavily investing in to bring battery manufacturing from scratch. Looking towards Korea and China, we see battery manufacturers looking to expand capacities and produce new factories. The fluidity in this ecosystem is making it imperative that battery manufacturing becomes increasingly democratized, and more data driven rather than experience-driven.

As companies worldwide invest in capabilities that enable localized production, the innovations adopted in this industry will set a precedent for the broader manufacturing landscape. Embracing smart manufacturing is an essential step towards a sustainable and advanced future in battery manufacturing.

Siemens Digital Industries Software helps organizations of all sizes digitally transform using software, hardware and services from the Siemens Xcelerator business platform. Siemens’ software and the comprehensive digital twin enable companies to optimize their design, engineering and manufacturing processes to turn today’s ideas into the sustainable products of the future. From chips to entire systems, from product to process, across all industries. Siemens Digital Industries Software – Accelerating transformation.