Tessent LBIST with Observation Scan Technology Wins Elektra Design Tool Award 2020

A Tessent technology was awarded the 2020 Elektra Design Tools and Development Software Award from a crowded field of nominated technologies. The winning technology is Tessent LogicBIST with Observation Scan Technology (LBIST-OST), which helps automotive ICs meet functional safety requirements. The judged award is presented for a product that excels in performance, innovation, and contribution to the global electronics industry.

Here’s what you should know about Tessent LBIST-OST.

Tessent LBIST-OST addresses ISO 26262 quality and safety requirements

To meet the ISO 26262 requirements for high quality and long-term reliability, it is important to implement on-chip safety mechanisms that can achieve an extremely high defect coverage of the logic. BIST is a standard mechanism for on-chip testing through the lifecycle of a device. However, traditional LBIST poses two challenges:

- It often cannot meet the 90% coverage goal required for Automotive Safety Integrity Level (ASIL) certification

- Fault detection happens only during the capture phase of each LBIST pattern

Tessent LBIST-OST was developed to improve test quality and reduce in-system test time by capturing test responses from the circuit during scan shifting for the observe point flops. Tessent LBIST-OST is the only technology on the market that can configure scan chains to capture test responses during both scan shift and scan capture cycles, significantly reducing the test time interval. A faster test time interval means more test patterns can be run and any defects in the operation of the system will be detected quicker, enhancing the safety of the system. Empirical results gathered from industry designs show that LBIST-OST enables 90% test coverage with up to 10x fewer LBIST patterns when compared with previous industry-leading LBIST solutions.

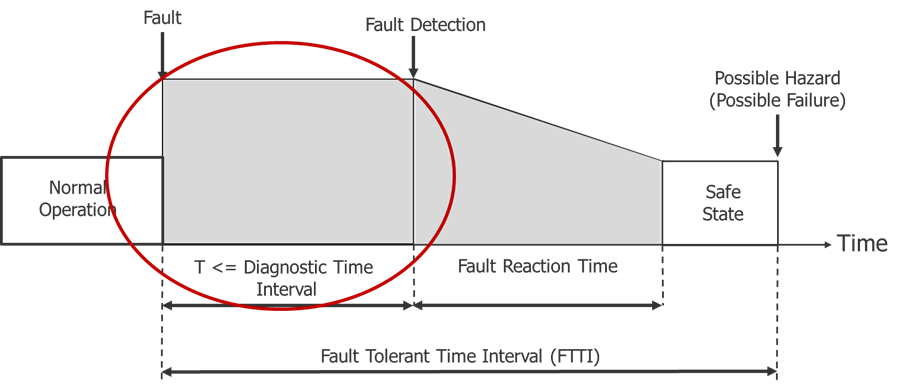

More about the test time interval: The complexity of automotive electronic devices continues to increase and the use of structural testing has become more critical. For large, complex designs, the structural test time often exceeds the required diagnostic test interval (DTI) and hence, the fault-tolerant time interval (FTTI). If an FTTI exceeds the safety goal, it then impacts the ability to achieve the required ISO 26262 certification level required for a given product.

By reducing test time and hence the DTI, any defect that might occur during the operation of a vehicle will be detected more quickly and the vehicle can respond more quickly due to the lower FTTI, reducing the chance of a serious incident. For our customers, the faster test time they achieve with Tessent LBIST-OST can make the difference between meeting ISO 26262 requirements or not, which affects their bottom line and competitiveness in the fast-growing automotive electronics market. For example, one of our customers was able to achieve a 6 millisecond test time with their incumbent LBIST solution, but they needed a 1 millisecond test time to reach ISO 26262 certification. With Tessent LBIST-OST, they reduced their test time to 0.5 milliseconds.

How does Tessent LBIST-OST work?

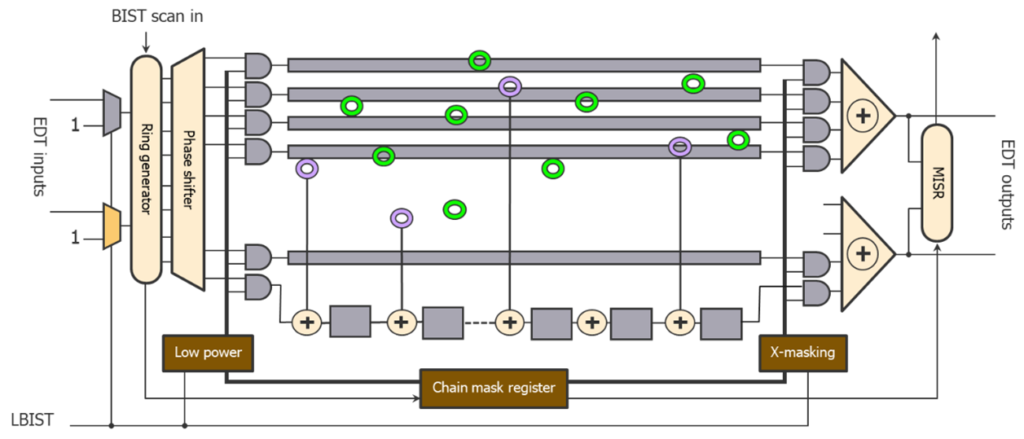

Tessent LBIST-OST uses unique control and observe test points. The LBIST-OST observe points use a new scan cell functionality that essentially connects the observe points in separate chains. This allows them to capture circuit responses not just during a capture cycle, but also during the shift cycles. To reduce the complexity of fault simulation, the observe points only observe test responses, and provide no test stimuli to the gates. Silicon area used by LBIST-OST is kept to a minimum by sharing the flip flops between a number of these observation test points.

To reduce external test data volume and pseudorandom pattern count, the observation scan chains are continuously shifted into the compactor, which drives the MISR signature generation. These observation scan chains are also shared with traditional LBIST scan chains, delivering responses once the entire test pattern has been shifted-in.

Both the Tessent LogicBIST tool and the LogicBIST IP are qualified through the ISO 26262 functional safety standard for automotive ICs. SGS-TUV Saar has certified qualification reports for the Tessent LBIST product up to TCL 1 for any tool confidence level and the generated LBIST IP up to ASIL D.

Learn more about how Tessent LBIST-OST can help you meet ISO 26262 requirements, read our white paper.

You may also be interested in hearing about the use of LBIST-OST on a real-world design. This video features Daniel Tille of Infineon describing their experience with Tessent on an automotive MCU design.