What’s new in Plant Simulation? (August 2021)

Digital Manufacturing – Optimized

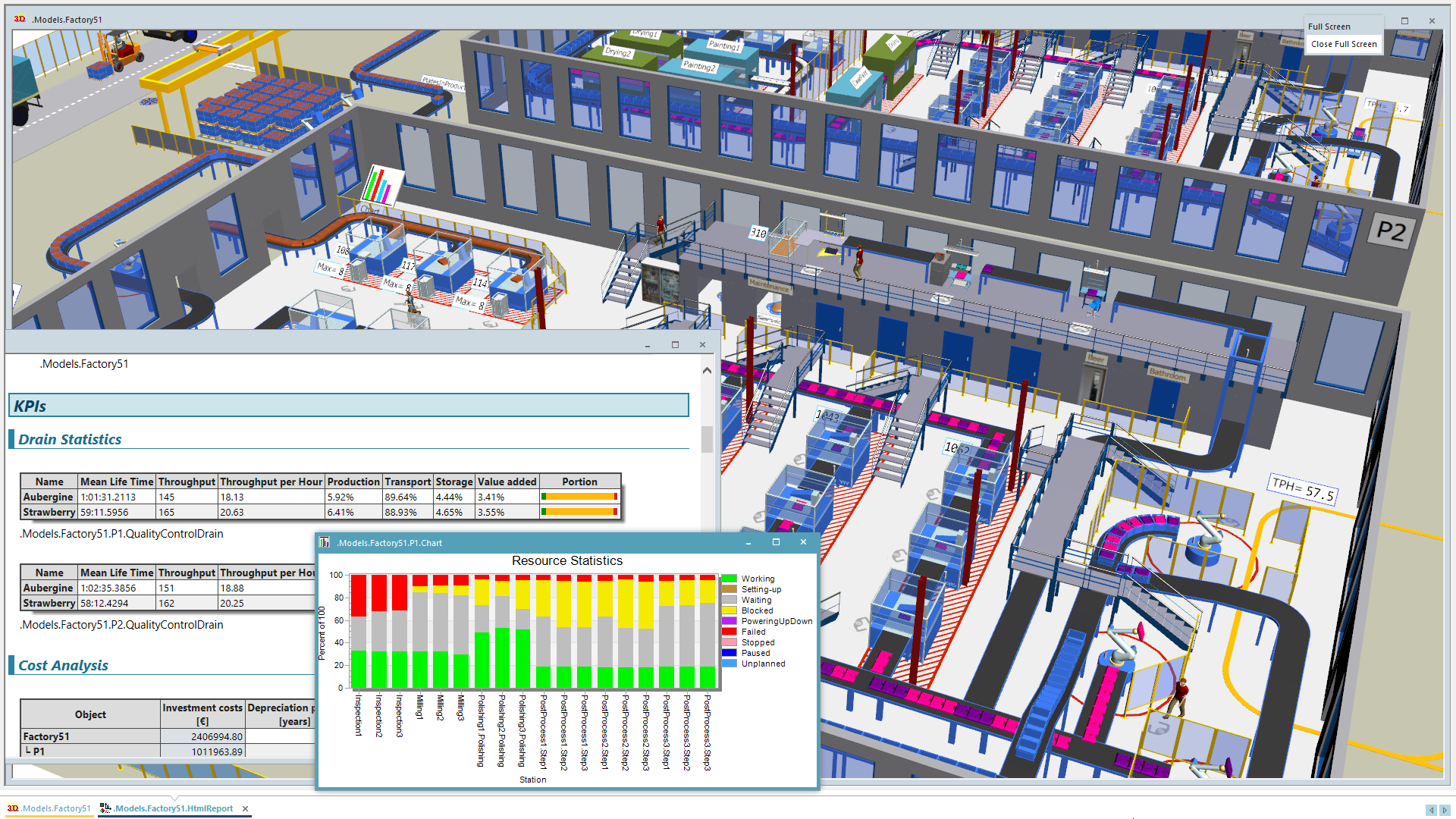

Plant Simulation in the Tecnomatix® portfolio optimizes manufacturing by modeling and simulating scenarios for production systems and their processes. By analyzing material flow, resource utilization and logistics for all levels of manufacturing planning from global production facilities to local plants and specific lines, Plant Simulation software gives manufacturers the ability to find their optimal designs well in advance of production execution.

Tecnomatix Plant Simulation 16 delivers new advancements for continued optimization. Version 16 offers a completely new way of working with automated guided vehicles (AGVs), vehicles driving on the floor independent from a fixed track system. It includes a new KANBAN-like material pull strategy based on a supermarket concept with automatic part reordering to get to leaner manufacturing.

New support for the JSON data type simplifies state-of-the-art web services communication with your simulation models. A host of new capabilities make managing simulation models easier, including seamless updating of models created with the Teamcenter Wizard, as well as improvements in PLM collaboration.

In addition, numerous material flow and user experience enhancements for existing simulation objects simplify and speed-up working with Plant Simulation.

We hope you find this new release valuable! Please let us know what you think in the comments section below.

Don’t have Tecnomatix Plant Simulation? > Try it for free.

See the highlights from Tecnomatix Plant Simulation 16:

Advanced AGV driving control access pattern

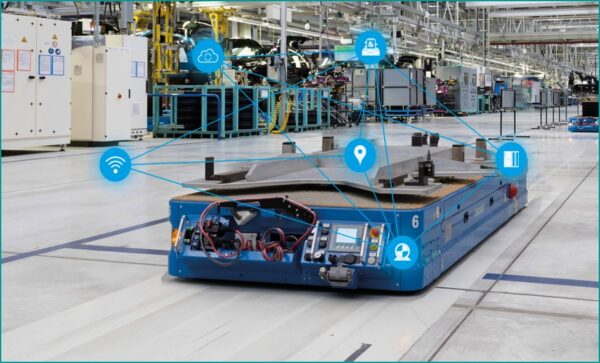

Plant Simulation 16 offers a completely new way of working with automated guided vehicles (AGV), vehicles driving on the floor independent from a fixed track system. Now you can define your own fleet manager driving and control strategy for testing purposes. You can also connect external fleet manager control software to a Plant Simulation AGV model. This allows support for virtual commissioning use cases for external fleet manager software.

AGV simulation for advanced production logistics

Nearly all industry types need to bring more flexibility into their production systems. Small lot sizes and one-piece flow are the result of personalized production orders. Today‘s production systems with product-driven material routing and late scheduling or station assignment answer these flexibility challenges. Tightly connected conveyor systems or overhead monorails are being replaced by smart AGV systems where each AGV can be controlled individually.

A new set of driving and control functionalities for the Plant Simulation transporter object allows users to simulate and optimize advanced AGV systems in Plant Simulation.

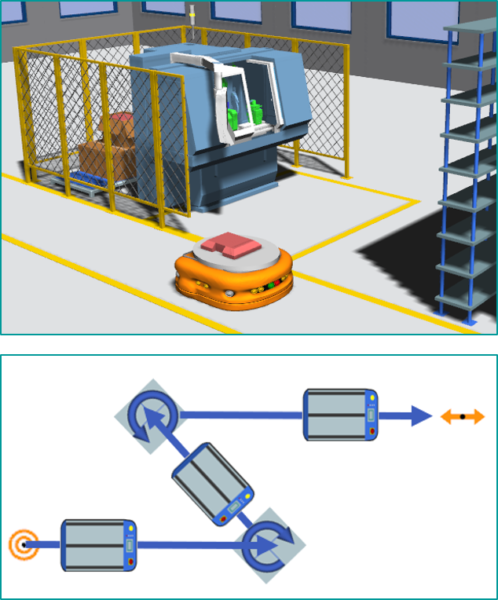

Flexible AGV system: Advanced driving control pattern

Vehicles in flexible AGV systems need to be able to drive on the floor, even without a fixed system of driving tracks. The new enhanced Plant Simulation transporter/AGV object supports this type of floor driving. Several additional driving patterns are included, such as rotation around the z-axis and driving in any direction.

We have also introduced special driving marker objects to define the AGV route. Using a single marker or a list of markers as the driving route, the transporter will find its way along the markers. Of course, the AGV uses its driving parameters like speed and acceleration, curve radius and rotation speed.

Using this new functionality you can easily define your AGV control directly in Plant Simulation and test and validate its performance with the simulated digital twin of your production.

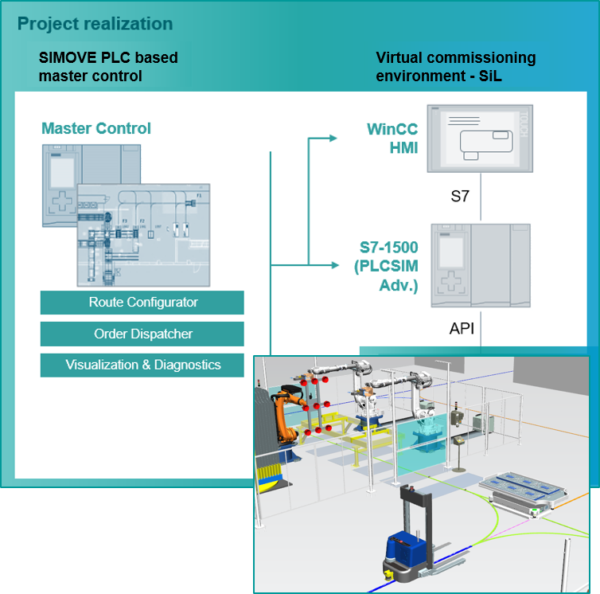

Flexible AGV system: Virtual commissioning of fleet management software (e.g., SIMOVE)

Virtual commissioning interfaces (PLCSIM Advanced, OPC UA, TCP/IP) allow you to connect Plant Simulation AGV system models to external fleet manager software. This opens up virtual commissioning scenarios for a fleet manager‘s control logic and performance.

Now you can more easily validate fleet management control strategies and HMIs under realistic conditions, overall KPIs, and AGV control and routing strategies, delivering mature fleet manager software to the shop floor and factory acceptance testing.

For the Siemens SIMOVE fleet management solution, you can accelerate your projects with the dedicated Plant Simulation SIMOVE transporter library.

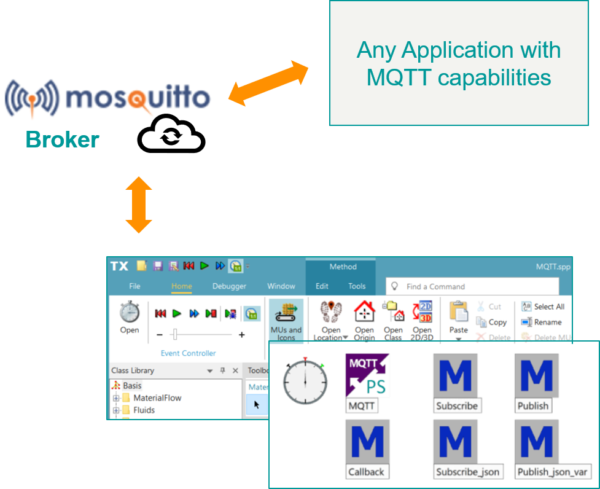

AGV virtual commissioning – MQTT client interface for IIoT communication

New in version 16 is support for the MQTT (Eclipse Mosquitto – https://mosquitto.org) client interface for IIoT communication.

The MQTT protocol provides a lightweight method of carrying out messaging using a publish/subscribe model. This makes it suitable for Internet of Things messaging with a wide range of applications, tools and machinery.

Return to top. ^

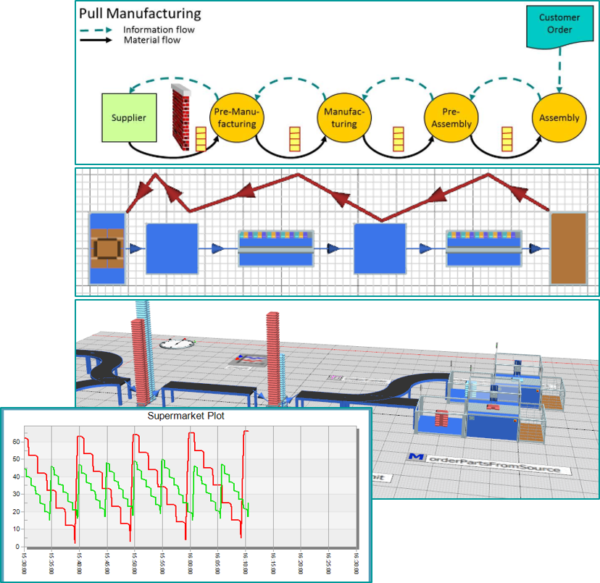

KANBAN-like material pull strategy for lean manufacturing systems with low work in progress (WIP)

Version 16 introduces a new KANBAN-like material pull strategy. This strategy is mainly based on a supermarket concept with automatic part reordering when the stock goes down. The supermarket with stock capacity and reorder level settings for many part types in parallel is the beating heart of the automatic material pull. It helps reduce the work in progress (WIP), and leads to lean manufacturing.

Supermarket and material pull for lean logistics

Organizing and parametrizing the supply chain for parts and assemblies is an important task for creating a well performing lean production system. The new KANBAN-like material pull strategy simplifies and speeds up the creation of part logistics in your simulation model using the Plant Simulation supermarket.

In a typical material flow simulation model, you must set machine and process parameters like machine availability and part processing time per machine. In most cases, you also must reflect the inbound supply chain for parts and assemblies in your production system, ensuring there are no part shortages during production.

This leads to value stream and Kanban methodologies that keep WIP low and throughput time for products high. Central members of such KANBAN supply chains are supermarkets or fulfillment centers with part-specific reorder logic. The new Plant Simulation supermarket has a built-in standard for such a demand-driven part reorder strategy, sending requests for new parts automatically to a part supplier in the model.

Based on this new functionality, you can easily define simulation experiments and find the best supermarket configuration parameters, such as upper stock and reorder level per part type.

Return to top. ^

JSON datatype to communicate with web services

Simulation models require several input data sets, including production orders, shift system and staffing configurations, production parameters, machine state information and so on. The new JSON data type simplifies state-of-the-art web services communication with your simulation models, accommodating all of these types of input data.

You can directly use JSON-formatted data provided by web services in the SimTalk scripting language. JSON is the abbreviation for JavaScript Object Notation, a simple text file format for structured data of any kind.

Return to top. ^

Teamcenter Wizard to Plant Simulation with enhanced simulation model update

The Teamcenter Wizard now fully supports updating of simulation models that have been created with the wizard and Teamcenter data from an earlier project phase. The Teamcenter Wizard helps more and more simulation engineers perform standard use cases with Teamcenter data imported into Plant Simulation.

Now you can update Plant Simulation Models with new planning data, import and update processes and operations, add and delete stations and machines, embed material flow simulation in iterative planning workflows, and much more. This becomes your single source of truth for planning data.

Return to top. ^

PLM collaboration enhancements

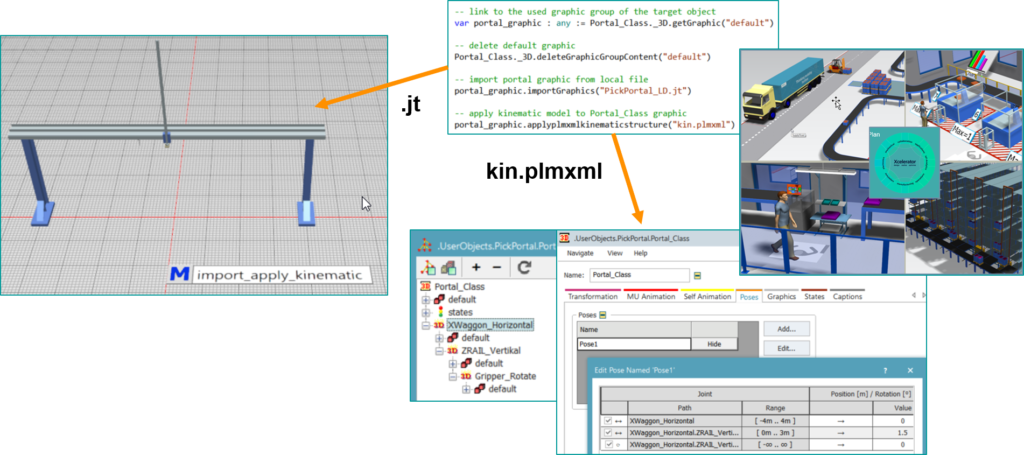

Enhancements in PLM collaboration make working with managed data in simulation models easier. Manual kinematic import through Teamcenter can now use export files created without readable references to Teamcenter. This is supported through the SimTalk interface.

Enhancements include data sharing and reuse in a PLM context, import and use of PLMXML kinematics, improved security and access control for PLM data used in Plant Simulation models, seamless PLM workflows for planning and engineering, and tighter PLM integration with Plant Simulation.

Return to top. ^

Material flow and user experience enhancements for increased modeling productivity

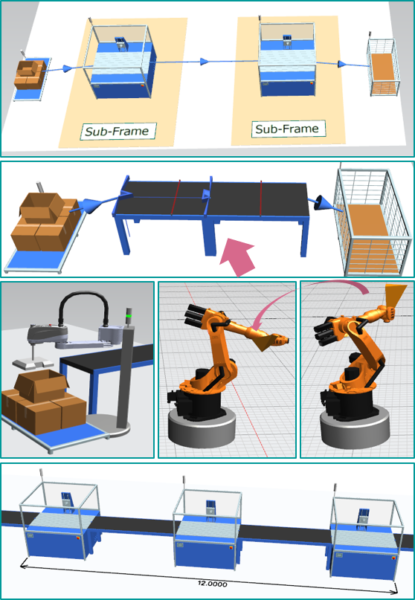

Numerous additional material flow and user experience enhancements for already existing simulation objects simplify and speed-up working with Tecnomatix Plant Simulation. Enhanced connectors simplify the setup and use of user-defined frame objects, making work with modules and stations much more intuitive.

Plant Simulation 16 includes simplified layout changes for conveyor and track systems, workplace with capacity functionality (many operators at a station), support for 6-axis robot kinematics in 3D Pick&Place and robot objects, predefined SCARA-type Pick&Place robot/kinematics in 3D, dimensioning graphics in 3D views, more flexibility in forwarding dismantled parts from the Dismantle Station, automated creation of rack graphics sensitive to rack and slot parameters, and sequential indexing for the PlaceBuffer object to support buffer line behavior often used in discrete part manufacturing.

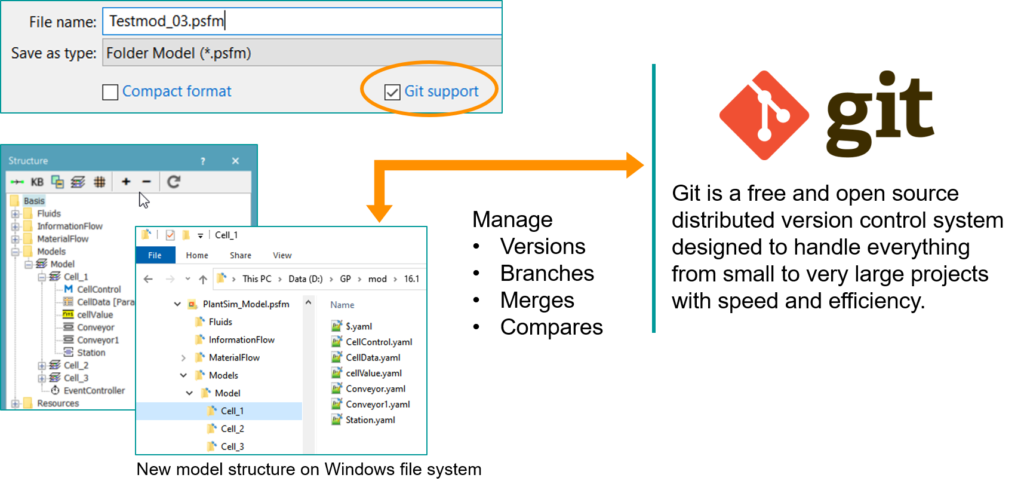

Version 16 includes direct import for NX part files, eliminating the need to first produce a JT file. We have also implemented a file/folder saving format enabling Git and SCCS usage to support collaborative model development within groups of simulation engineers and to ensure simulation performance and modeling ease-of-use in large-scale models.

Git and other source code control system (SCCS) tools can detect and show differences in branches of your simulation model files. This allows you to highlight model differences in changed or new model sections, accept or discard the changed content, and merge model branches to a new model version.

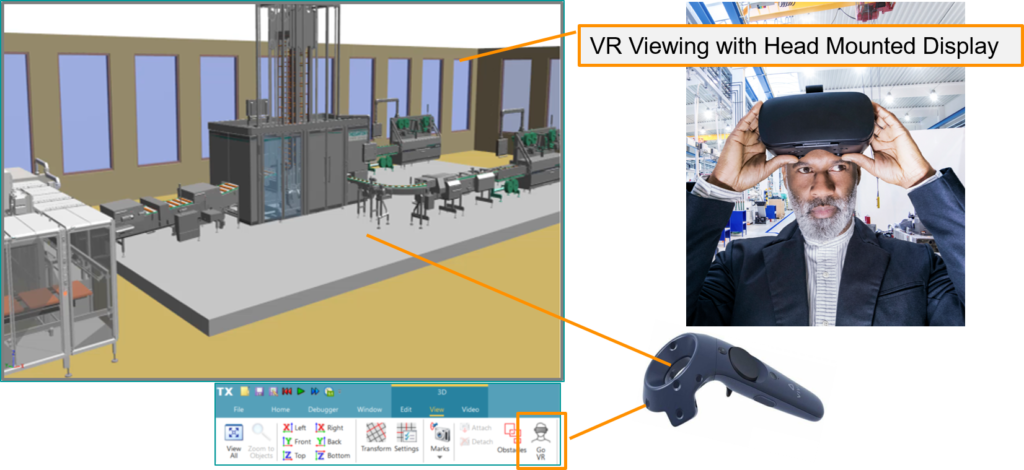

Plant Simulation 16 gives you the ability to directly immerse yourself in the model for virtual reality animation using an HTC Vive head-mounted display and controllers. In previous versions, this was only possible with third-party add-on applications.

Return to top. ^

—–

These are just highlights of the many user experience advancements delivered with version 16. For complete details on the new features of Tecnomatix Plant Simulation 16, please refer to the release notes offered with the software download.

And, as always, hop on over to the public community, corporate blog, and website for all things Tecnomatix.

Yours in digital manufacturing optimization,

(on behalf of the entire Tecnomatix Plant Simulation product team)

Don’t have Tecnomatix Digital Manufacturing? > Try it for free.