Creating a digital twin for rapid digital and physical transformation

Aging Aircraft Solutions uses Tecnomatix Plant Simulation software to increase productivity for the U.S. Air Force Air Logistics Complex

Aging Aircraft Consulting is a business engineering services company that focuses on sustaining aging aircraft for military and commercial customers. For 20 years, Aging Aircraft has delivered aerospace engineering, reliability and maintainability engineering, logistics services, and new technology insertion. They actively partner with their customers to improve reliability and maintenance programs essential for mission assurance, cost reduction and high performance.

At Realize LIVE 2020, Siemens’ global customer event, Aging Aircraft presented their development of a digital twin for the U.S. Air Force’s Warner Robins Air Logistics Complex using Siemens Tecnomatix® Plant Simulation software. This blog summarizes their presentation.

The manufacturing challenge

The U.S. Air Force’s Warner Robins Air Logistics Complex (WR-ALC) provides Programmed Depot Maintenance and unscheduled repair activities on F-15, C-130, C-5, and C-17 aircraft. The base provides for the repair, modification, reclamation, and rework of over 200 aircraft worldwide and is responsible for over 60 repair and overhaul processes.

WR-ALC management needed to improve the productivity of repair and manufacturing product lines. They wanted to benchmark repair process performance and conduct “what if” analyses of proposed changes using a richer data set to aid in their strategic decision making. In this pursuit, they wanted to adopt advanced manufacturing technology.

As WR-ALC began their digital transformation journey, they had no existing process models. Process data was stored in data systems that were hard to use, with manual data collection processes, and modifications to their processes on the fly were difficult.

WR-ALC partnered with Aging Aircraft to develop and deliver a digital twin of the Product Overhaul Re-Manufacturing Line to provide a platform for Industry 4.0 advanced manufacturing functionality. Their goals were to reduce the investment required in planning facilities and processes, and to improve the productivity of existing facilities and processes. They needed to increase their responsiveness to changing conditions and better understand the effect on productivity of various configurations.

Ultimately, they wanted to build quantitative business cases for proposed process and facility changes using simulation data.

The digital transformation approach

Aging Aircraft applied Siemens advanced manufacturing capabilities to leverage digital twin models of WR-ALC machines and processes. Data from sensors and IoT networks would populate those models, allowing scenario planning and increased flexibility and responsiveness to market demands.

Aging Aircraft designed a reconfigurable manufacturing system with six core characteristics, including:

- Modularity – compartmentalization of production functions

- Integrability – material transport system integrated with machine modules

- Customization – system flexibility around the prominent propeller parts

- Scalability – characteristics of affect at a machine (low) level or system (high) level

- Convertibility – ability to transform functionality

- Diagnosability – ability to read the current state and to detect and diagnose causes of constraints

The project roadmap started with research into current operations and data collection at the WR-ALC complex. They then developed the digital twin of the facility and virtual work instructions for each process step. Finally, they were able to focus on virtual planning and commissioning, delivering scenario analysis and reports.

The digital twin and Tecnomatix Plant Simulation

A comprehensive digital twin represents in the virtual realm every aspect of a product’s life, from design through in-use performance, including the processes employed to manufacture the product. The comprehensive digital twin is used to simulate, predict, and optimize the product and production system before investing in physical prototypes and assets. This virtual asset reduces engineering planning time, improves communication of changes, enables virtual commissioning of new equipment and processes, and tests the economic architecture with respect to revenue, profit, ROI, and cost optimization.

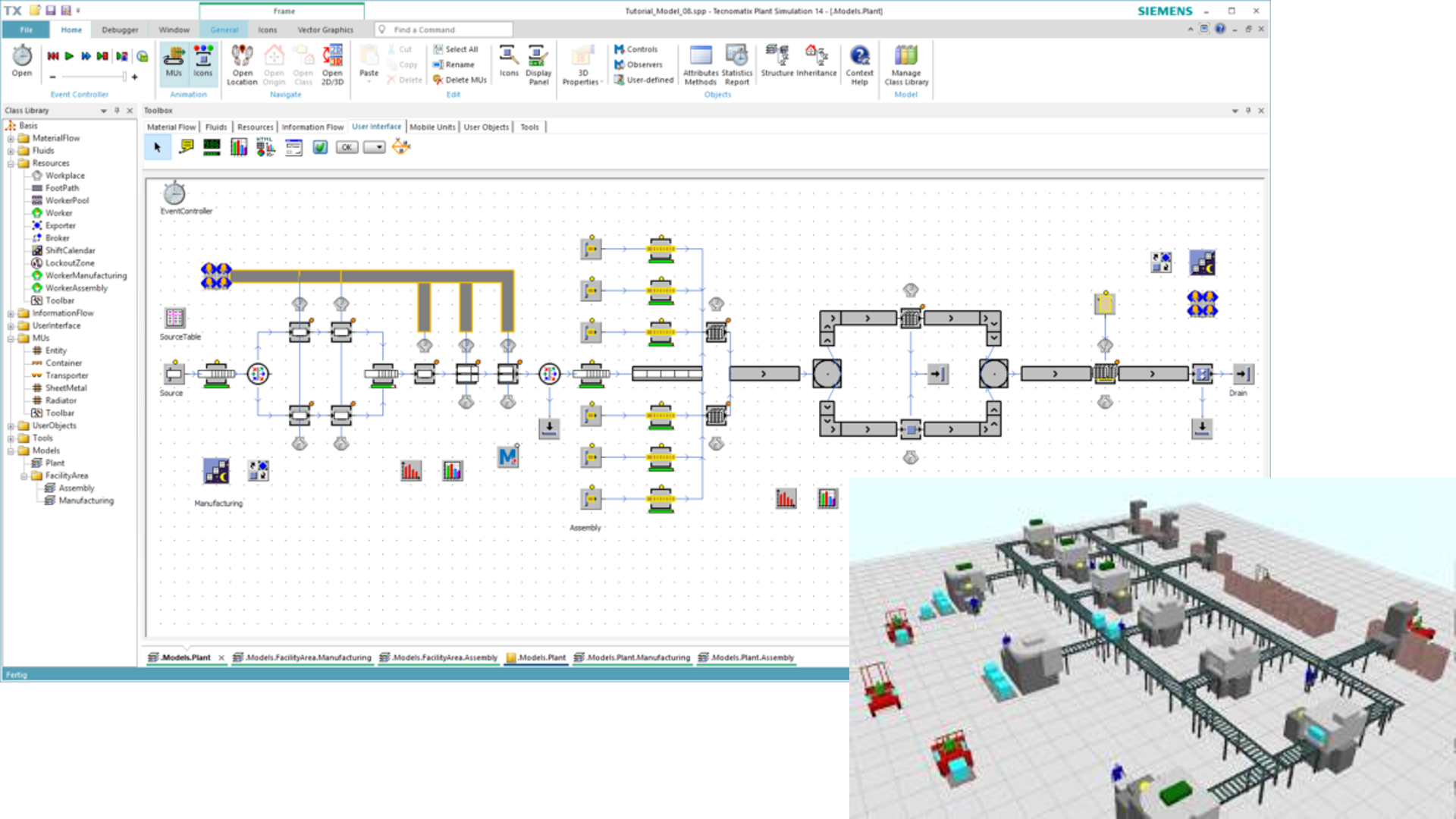

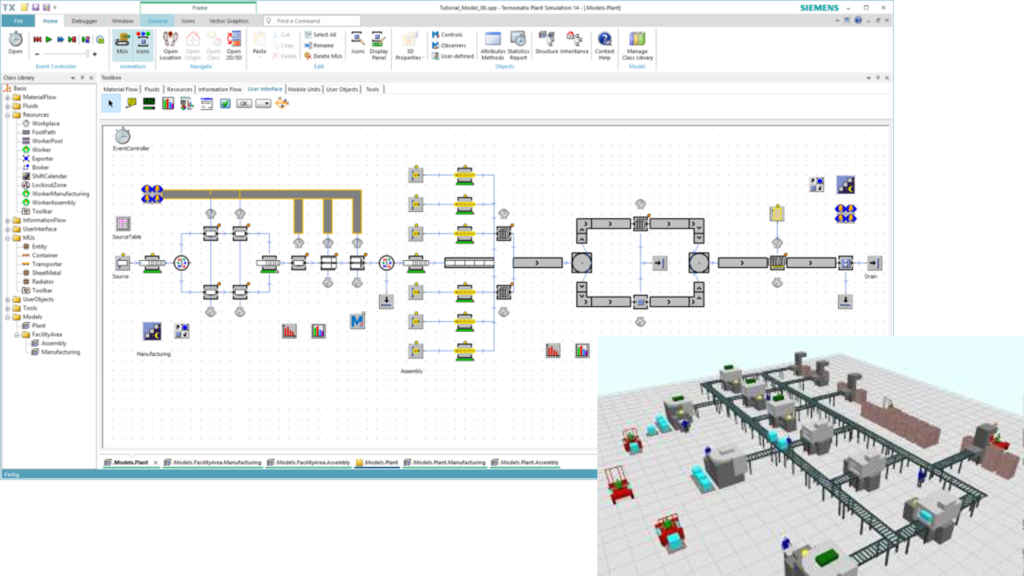

Aging Aircraft implemented Tecnomatix Plant Simulation software to perform discrete-event simulation of the entire repair line. Their virtual environment implementation included the laser scan facility, 3D model area, virtual layout, and virtual commissioning.

The virtual manufacturing tool was layered for different functionalities and use cases centered around the manufacturing process. First, the process step data for the cells was created, followed by the process step simulations. On top of that, they placed a 2D model of the process, and finally 3D visualizations were added. This provided the environment in which they could conduct virtual commissioning and plant layout analysis to reduce reconfigurable switching costs and improve overall efficiency.

Results – optimizing productivity

Aging Aircraft was able to create their virtual manufacturing tool in only 4 months. The first two months were dedicated to research while they scanned and compiled point cloud data. The next month was dedicated to encoding the 2D process flow map and building models of equipment. Finally, the last month was used to map locations of the process steps and increase the level of fidelity.

Several use cases have been run using the digital twin. They have been able to perform what-if analysis to produce impact on process cells and the overall process line. They have also been able to understand the impact of adding, removing, or changing equipment locations. They simulated de-bottlenecking scenarios, process flow troubleshooting, and process and equipment change impact to provide business cases for change.

Vision for the future

With a comprehensive digital twin in place, WR-ALC will continue to add data to the virtual manufacturing tool, as well as new capabilities to their overall advanced manufacturing infrastructure. Their vision for the future includes using augmented reality/virtual reality (AR/VR) technology, accessing the AR cloud, providing information overlays and visual analytics, and creating more effective skills training.

Siemens continues to partner with leaders across manufacturing industries to build products and systems that improve sustainability, safety, quality, and compliance, allowing them to better serve their customers, and contribute to a more prosperous world.

—–