Optimization: Harnessing the power of Plant Simulation for planning and scheduling

We are pleased to announce the upcoming lecture, Production optimization: Harnessing the power of Plant Simulation for planning and scheduling, as part of the 2023 Plant Simulation User Conference, Munich, Germany, July 13th 2023, just after Realize LIVE Europe. This lecture aims to explore the application of Plant Simulation for optimizing production processes and improving planning and scheduling efficiency.

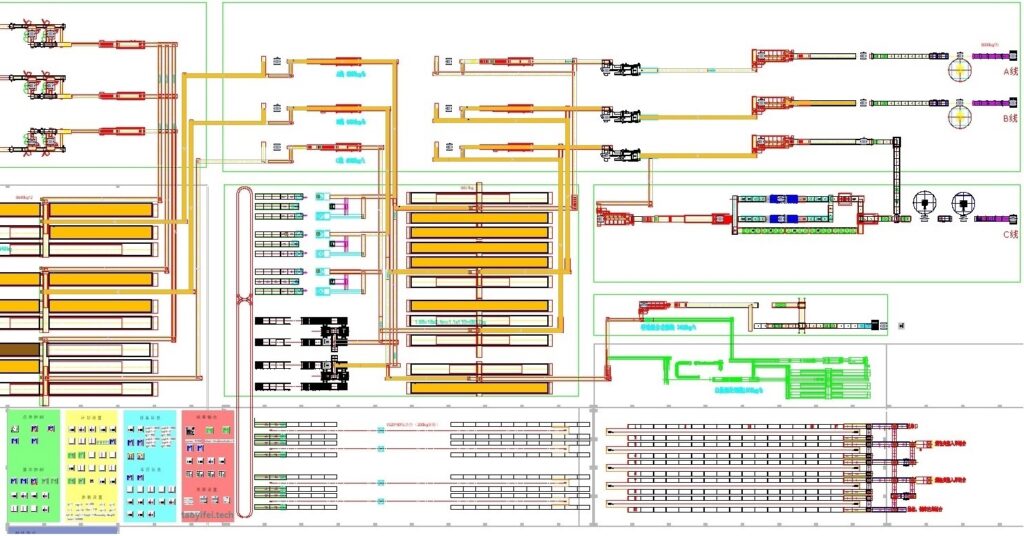

Simulation for planning and scheduling

Plant Simulation software in consumer packaged goods (CPG) industry production planning and scheduling optimizes processes, improves efficiency, and enhances productivity. It analyzes capacity, identifies bottlenecks, and enables informed decisions for maximizing output. It develops optimized production plans and schedules, minimizes changeovers, and meets customer demands. With what-if analysis, manufacturers simulate scenarios and make data-driven decisions. It optimizes inventory management, reduces stockouts, and minimizes holding costs. In summary, Plant Simulation streamlines operations, increases profitability, and delivers high-quality products efficiently.

Since 2008, Mr. Tao Yifei has been actively involved in research on simulation modeling and optimization scheduling technology for complex manufacturing and logistics systems. He currently holds a position in the department of Industrial Engineering at KUST, China. With his expertise and years of experience, he contributes to the advancement of the field by exploring innovative approaches to enhance efficiency and productivity in industrial operations.

Established in 1954, Kunming University of Science and Technology (KUST) is situated in Kunming, Yunnan Province, in the southwest region of China. KUST is a comprehensive university with a strong focus on engineering disciplines.

Plant Simulation software in the Tecnomatix portfolio can be a valuable tool in the consumer packaged goods (CPG) industry for planning and scheduling purposes. It allows manufacturers to create virtual models of their production processes, simulate various scenarios and optimize their operations for improved efficiency and productivity.

Here are some specific applications of plant simulation in the CPG production planning and scheduling:

Production Capacity Analysis

Plant Simulation software helps analyze the production capacity of manufacturing facilities. By creating a virtual model of the plant, including all the machinery, equipment and production lines, manufacturers can simulate different production scenarios and identify bottlenecks or areas of inefficiency. This analysis enables them to optimize the layout, adjust resource allocation and make informed decisions to maximize overall production capacity.

Process Optimization

Plant Simulation software allows manufacturers to evaluate and optimize their production processes. They can simulate different process parameters, such as machine speeds, material flow rates and production sequences, to identify the most efficient configurations. By optimizing the production process, manufacturers can reduce waste and energy consumption, minimize downtime and increase the overall throughput of the production.

Production Planning and Scheduling

Plant Simulation software can assist in developing production plans and schedules for the individual manufacturing. By inputting various factors such as demand forecasts, raw material availability and production constraints, the simulation software can generate optimized production plans that balance production volumes, minimize changeovers and meet customer demands. It helps manufacturers to make informed decisions about production sequencing, resource allocation and capacity utilization.

What-if Analysis

Plant Simulation software allows manufacturers to perform what-if analysis by modeling different scenarios and assessing their impact on production outcomes. For example, they can simulate changes in production volumes, introduce new machinery, modify production lines, or test alternative production strategies. By analyzing the results of these simulations, manufacturers can evaluate different options and make data-driven decisions to improve the efficiency and effectiveness of their facility.

Inventory Management

Plant Simulation can aid in optimizing inventory levels and reducing stockouts or excess inventory in the CPG production. By modeling the production processes and demand patterns, manufacturers can simulate different inventory management strategies and determine the ideal inventory levels at each stage of the production process. This helps in minimizing inventory holding costs while ensuring sufficient stock availability to meet customer demand.

In summary

Plant Simulation software in the Tecnomatix portfolio is a valuable tool for CPG production planning and scheduling. It enables manufacturers to analyze production capacity, optimize processes, develop production plans, perform what-if analyses and optimize inventory management. By leveraging the power of simulation, manufacturers can improve efficiency, reduce costs and enhance their overall production performance.