Enabling digital collaboration through process simulation software

The opportunity to modernize digital collaboration in Process Simulate

Are you looking for a modern and efficient way to optimize your factory production lines in Process Simulate? Then look no further. Tecnomatix Process Simulate Collaborate was released on Tuesday, February 14th, 2023.

Digital manufacturing solutions like the Siemens Tecnomatix® portfolio, with a comprehensive set of product capabilities such as offline programming and virtual commissioning have enabled manufacturers, like you, to reduce the amount of downtime between production and increase productivity significantly by designing and simulating studies virtually.

Modern and innovative technologies have transformed the landscape of digital manufacturing. In an ever-evolving digital age, it is essential that manufacturers embrace digitalization to optimize production and to compete and collaborate more effectively. As physical distancing becomes the next normal, it is vital that manufacturers digitally enable operations to validate production concepts in advance.

Effective digital collaboration for better decision making

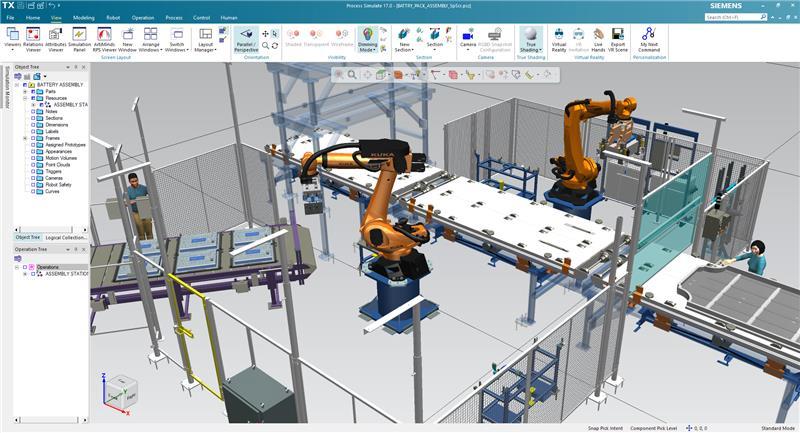

Behind a successfully manufactured product, there can be a series of rapidly assembling robotic systems and manual assembly systems combined with an interconnected team. Digital solutions like Process Simulate in the Tecnomatix® portfolio help define the robotic assembly, from single-robot stations to complete production lines and zones. Process Simulate helps manufacturers achieve time-savings through fast path creation, collision-free trajectories, and reliable cycle-time results. That way, manufacturing teams can verify processes and virtually validate concepts in a 3D environment.

It’s important that manufacturing teams synchronize their production system and product development processes. The interactions between cross-functional teams and processes must be seamless to deliver a high quality and competitive product at the right time and right cost. Using a robotic simulation software such as Process Simulate, it is essential that the manufacturing, engineering, and mechanical teams be on the same page to enable faster, better decisions that drive bottom-line value.

For Process Simulate studies specifically, there needs to be a dynamic 3D environment for users to join or lead a collaborative environment anywhere, at any time. From programming to validating, this type of real-time collaboration on Process Simulate studies would enable faster and clearer communication and accelerate time to market. Otherwise, changes applied in the design or simulation phase risk missing the cycle time and time to market. In addition, change requests to Process Simulate studies become cumbersome to track, which is why a seamless and secure way to improve collaboration with internal and external users using 3D visualization and simulation would create an optimal outcome.

Connecting Manufacturing Teams

Manufacturers need a simple and managed way of sharing Process Simulate studies both internally and externally to increase productivity in their design and simulation operations to optimize their value chains. Simultaneously enabled digital collaboration is the key to achieving this. The challenge lies in not just bringing the product’s cycle time and time-to-market down by a significant margin, but also the various other ways in which your collaborative manufacturing workforce can eliminate downtime at various levels of the product lifecycle.

A next level digital manufacturing software for Process Simulate studies would help engineering teams collaborate by consistently reviewing, editing, sharing work studies, and providing location-specific role access, all components which are instrumental to maximizing productivity and efficiency on the shop floor.

Are you ready to optimize your production lines and collaborate on Process Simulate studies more effectively? If so, then you’ve come to the right place! Tecnomatix Process Simulate Collaborate is an intuitive, highly visual simulation software designed to bring together teams of all sizes and capabilities to collaborate and innovate more efficiently on Process Simulate studies.

This 3D visualization platform helps to speed up Process Simulate workflows and increase productivity, enhance communication and collaboration, and improve team performance. With different collaboration features such as sharing a study, collecting feedback, and on-the-go management, the software makes it easier than ever to get the best out of your teams and make your Process Simulate projects run smoother.

In the next blog series, we will dive into how manufacturers can eliminate the traditional way of collaboration through messy email chains, static images with markups, and slides by adopting cloud-based systems that enable teams to collaborate more effectively. It’s time to modernize communication with a digital solution that drives efficiency and brings human robot collaboration to the next level.