50 % decrease in drop inventory. Simulation helps with analysis, optimization, and with execution.

Simulation cannot only help with analysis and optimization, but also with execution. This customer example, based on a presentation at the Plant Simulation Users Day 2022 in Berlin, pulls its astonishing results from feeding simulation data into a customer specific manufacturing system.

Using a Simulation Model for Better Execution

THK of America broke the Plant Simulation plan down into three major steps:

- Capture floor data to build an accurate model.

- Validate the simulation model to assure accuracy.

- Generate optimization parameters to allow the simulation to increase efficiency.

Three Steps Towards a Working Model

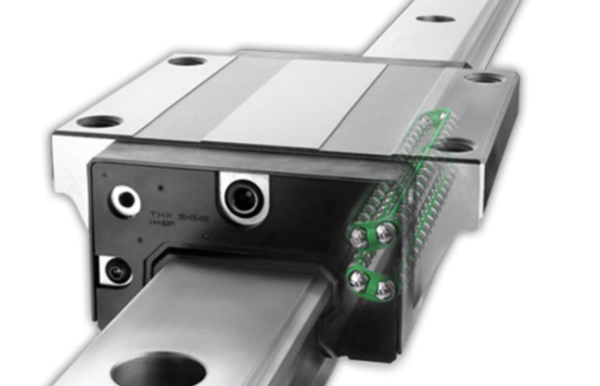

For the first goal, capture floor data, the team already faced a plethora of challenges. With the customizability available for THK’s rails, multiple different properties can affect processing time and overall workflow.

THK solved this by building a timing library that includes all of the machines, part types, and processing times. The team spent long hours working closely with production staff to fully understand the intricacies of each step in the cutting process.

To tie all this together, the team utilized custom SimTalk functions to parse each rail, and determine what happens to the rail before, during, and after being cut.

The next major milestone was to validate the simulation model. The variability in the product flow required using daily historical data and running it through the simulation. Utilizing the Experiment Manager, each day was run as an experiment. This generated multiple possible scenarios, accounting for machines in maintenance, employees taking the day off, etc. This system was used to continue iterating the model until the simulation results came close to a satisfactory threshold of the daily real-life results.

I came from not knowing what Plant Simulation was, to implementing this solution in just six months. Learning from the Siemens Xcelerator Academy, reading through the forums, and doing a deep dive into the online help all enabled my team to get up to speed quickly so we could produce this output.”

Daniel Abdelsamed, Manager DX team, THK Manufacturing

After that, the results are captured in an external software that sends them to the central DX data system. To provide an overview, Plant Simulation runs the optimizer and generates results. Afterwards, a Javascript server running on Windows captures those results via the COM system. The COM system is also runs the optimizer upon request or on a time basis, like once a day.

Finally, all this data ends up in the central DX data system, which is a custom system developed to handle all of THK’s data from Plant Simulation and all other sources. This basically is the single source of truth for digital information. The DX system is built on Linux servers running Kubernetes. This allows THK to run all applications (including Plant Simulation) in a redundant and resilient way. The central system outputs a data graph which can be used by multiple other applications.

From Simulation to Better Execution

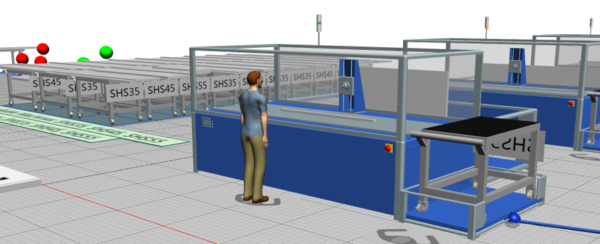

THK Manufacturing: Siemens Digital Industries Software Tecnomatix Plant Simulation offers all means to improve automatic and manual processes.

Finally, the simulation generates rail groupings, which are executed in a single batch on a single machine. It specifies exactly how much stock has to be released from the warehouse and which drop rail to use. In addition, the warehouse team knows exactly when the order has to be released to be on schedule. Once the drop rail arrives at the cutting process, the team knows when to start processing that group.

Providing Manufacturing Information

Successfully running a process requires data. At THK the following sample applications pull information from the central DX data source.

A web application for the warehouse team shows which material needs to be released next. The warehouse team can see which orders are on that cart, and what stock needs to be released for it. The team can also print the cutting plan in preparation for the operators to use it.

The operators can view the digital signage to the machines. These signs instruct the operators which task needs to be executed plus their current priority. This information is kept up to date when a task with a higher priority comes through. The operators also use the plans printed by the warehouse team to set the machines up for the cuttings.

The scheduling team can access the current orders and their machine allocations. This team can analyze the simulation forecast, and update order due dates, plus future process schedules to account for the changes as well. In addition they can download the order queue dataset for further analysis.

Overall Results

After only 15 days of running the system, we found a 50 % decrease in drop inventory. The old system wasn’t able to fully utilize the drop or required manual intervention to do so. Our system was able to re-release those rails more efficiently and completely autonomously.”

Daniel Abdelsamed, Manager DX team, THK Manufacturing

The productivity in the cutting process increased with a more predictable output. The scheduling team also unveiled a decreased workload in the cutting facility, so they could focus their time and effort communicating with customers and forecasting.