Charging innovation powers the future of EVs

The market for electric vehicles is growing fast but finding efficient ways to “refuel” these vehicles will rely on building new infrastructure.

The world of electric vehicles is beginning to boom. While it has been a slow process toward heavy adoption, the market is undeniably growing as more and more major car manufacturers bring EVs into the fold.

One of the biggest roadblocks (no pun intended) has long been infrastructure. The world is full of gas stations for refueling, but charging stations for electric vehicles have faced an uphill battle.

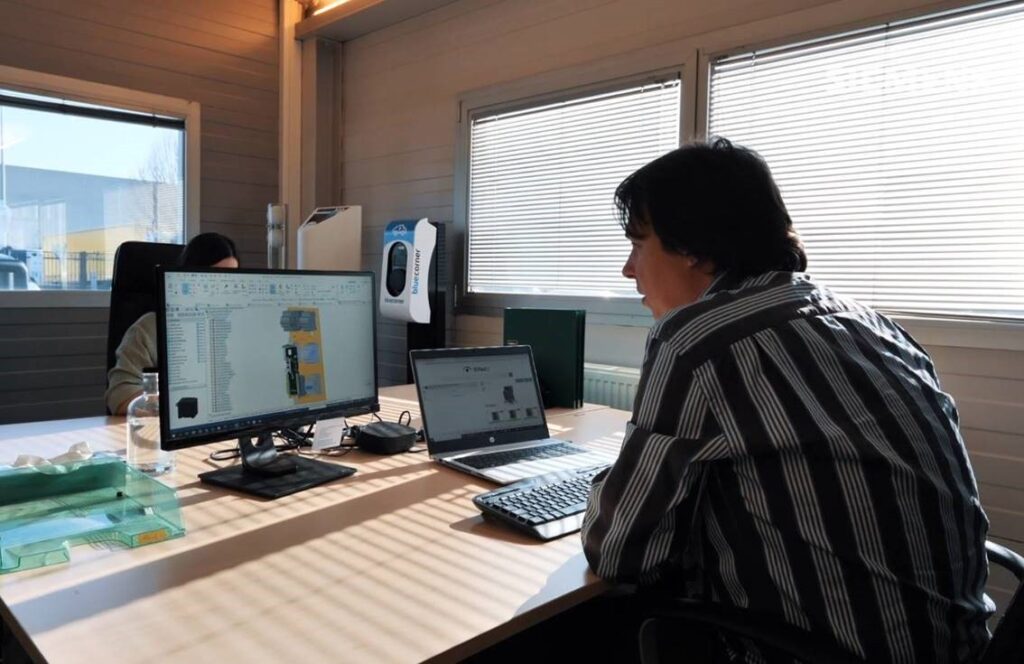

eNovates is an OEM/ODM designer and manufacturer for electric vehicle charging stations. “We specialize in AC charging stations and smart charging software. We do all the hardware and software development in house,” said Stijn Vispoel, R&D Manager at eNovates.

Building a business on infrastructure

eNovates employs about 50 engineers who work in everything from support and operations to (mainly) research and development. “We do not produce our products in house,” Vispoel explained. “We use our manufacturer network to assemble the products for our customers.”

The company was established in 2010 as a think-tank within a business club. From the beginning, eNovates’ focus has been on developing and producing charging systems and management software to support the electric mobility ecosystem.

“The early days at eNovates were not easy, since there was little market for EVs,” Vispoel said. “But the market started to take off in 2018, and eNovates started growing accordingly. Over the last couple years, eNovates has been increasing our workforce and revenue almost every year.”

Every business has challenges along the way, and while the market for EVs is growing, eNovates still has hurdles to overcome. The market for electric vehicles and their infrastructure has not yet matured, and Vispoel explained that there are a lot of changes and updates in regulations that vary from country to country. Because of this, products need to be (re)designed quickly to adapt.

“There are a lot of new players entering the market,” he went on to explain. “So there is a lot of price and innovation pressure from competitors. eNovates needs to be on top with smart designs and innovation to be one of the leading players in Europe. Beyond that, EV chargers are complex systems that are crossing multiple domains of engineering: electronics, electrics, mechanics, software. Having the right people and tools that can work across multiple disciplines of engineering can be challenging.”

Vispoel explained that the advantage eNovates has is their forward-thinking stance on product development. The company is truly interested in innovating products, and not just creating a single commodity to sell. Their products need to be designed and redesigned quickly to adapt to shifting regulations and power needs for EVs.

Product development in a shifting market

Developing products for infrastructure can be a challenge, especially when there are so many varying regulations and changing needs. eNovates uses a development process known as NPI (new product introduction) that has varying phases: proto, alpha and beta.

“At the start of the product design process, we gather requirements: client, internal, market and compliance. Then those requirements are split over the different domains to develop a first batch of prototypes,” he explains.

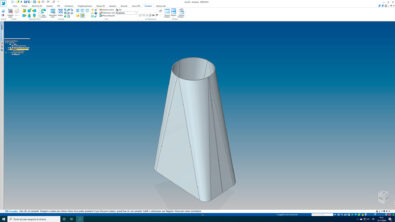

eNovates uses Solid Edge software from Siemens to aid in their design process. “We try to do as much evaluation in the software before making an actual prototype. After building the first prototypes, we do the first evaluations against the requirements. Findings are then used to make changes to the design during the alpha phase. Digital evaluation is performed and alpha samples are built to evaluate.”

Solid Edge for mechanical design is mostly used for making plastic or metal parts of enclosures. “We use Solid Edge a lot, together with PADS Professional from Siemens, to check if the developed PCB will fit in the enclosure. Furthermore, we also use Solid Edge Wiring and Harness Design for the electrical development in combination with Solid Edge Electrical Routing for cable routing,” Vispoel explained.

According to Vispoel, a beta batch is built by production while taking the remarks from the alpha build into account. This batch is used for the final evaluation with the customer and for certification purposes. If all of this is successful, the development phase is done and there is a handover to the operational team.

As the R&D manager, Vispoel and his team develop the hardware and manage projects. The design software they use is important because of the cross-discipline work and adaptation that is required within their business. Because developing charging stations is a multidisciplinary effort, the team felt it important to have a good flow between different software tools.

“Siemens was the only one in the market who made it possible for easy collaboration between the different tools,” he said. “[With tools that work well together] we can save time in development and check requirements already in our software tools before making a prototype. An example is the collaboration of Solid Edge for mechanical design in combination with PADS Professional from Siemens to easily check for collisions between the developed PCB and the enclosure.”

Growing for the future

As eNovates continues to develop their products and work with clients to help build an infrastructure for EVs, that means finding new tools to design and engineer components.

eNovates is working to grow their business through innovation, which includes both physical engineering and software engineering. The company’s “smart charging algorithm” is a load balancing algorithm that distributes the available power between a predefined group of chargers. According to eNovates, “the available current is distributed evenly among plugged in EV’s and PHEV’s. Each phase is processed independently to create a charging plaza with the highest efficiency on the market.”

But growth through innovation doesn’t just happen with products. eNovates is working to add to their capabilities internally as well, in order to create a more efficient business.

“Since we are growing rapidly, there is a need for structure in processes and tools,” Vispoel explained. “That is why we are currently implementing Teamcenter X from Siemens to work with our different software tools from Siemens: Solid Edge Mechanical Design, Solid Edge Wiring and Harness Design and PADS Professional. Thanks to eNovates implementing this new software, file, release, product lifecycle and task management will all be more structured moving forward.”

He continued, “For the future, we want to expand our business by making new innovative products and new partnerships to support the growing market of EVs. We are investing in people and equipment to make our company more professional and ready for the future.”

While the road to mass adoption of EVs has been slow going, it can’t be denied that consumer-level electric vehicles are here to stay, and they will only become more prominent. That means there will be an ever-growing need for charging these vehicles quickly and efficiently. Businesses like eNovates are helping to create the future infrastructure that will power our transportation in the years to come.

For more information about eNovates visit evovates.com.

To start a free trial of Solid Edge or learn more about our startup program, visit our website.

This Siemens-sponsored article was originally published by Engineering.com. Read original article →

Comments