What’s new in Simcenter Flotherm 2504?

Introducing new enhancements in Simcenter Flotherm 2504 software release. There is now easy IC package model creation in your thermal simulation workflow using the new Simcenter Flotherm Pack Module, and humidity modeling for datacenters and other applications. Read more below about the release and go to support center to download Simcenter Flotherm 2504 now.

Model the complexity

Generating IC package thermal models quickly and easily

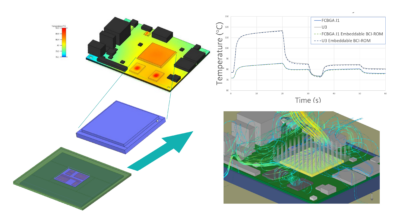

Creating chip package models, or sourcing them from vendors, for your thermal analysis purposes can be a time-consuming task for any thermal engineer. A new utility, licensed as the Simcenter Flotherm Pack module, helps you accelerate chip package model generation.

You can launch Simcenter Flotherm Pack from your desktop or from within the Simcenter Flotherm interface to generate common mono chip thermal model types quickly and easily. You can create detailed packages within this module and, then leveraging functionality in Simcenter Flotherm’s Command Center tool, you can also generate 2-resistor (2R) and DELPHI compact thermal models. All these types of models can easily be added to your Simcenter Flotherm libraries to make your thermal analysis process more efficient, supported with suitable choices of component model fidelity.

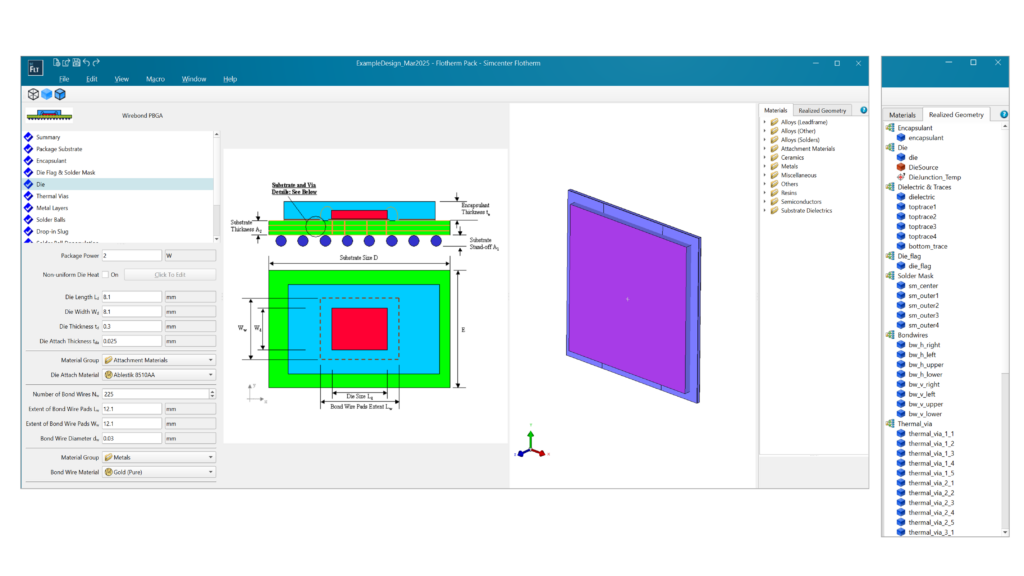

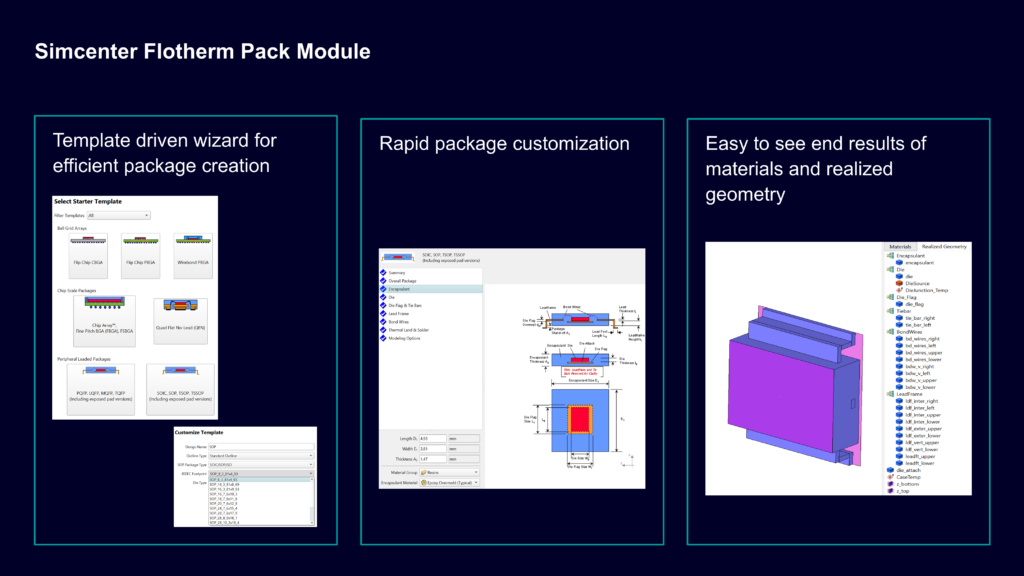

Creating detailed package thermal models with Simcenter Flotherm Pack Module

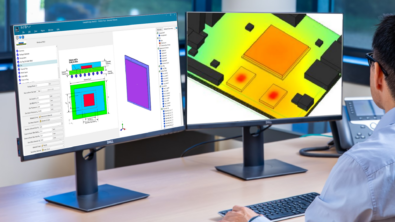

The steps for how to use Simcenter Flotherm Pack Module are summarized as follows:

- Select a common package type using a wizard driven template.

- Define the component’s geometry dimensions and specify its materials

- Transfer the model to an open Simcenter Flotherm project or save the model as a FloXML file type.

Simcenter Flotherm Pack Module creates a detailed thermal model which you can subsequently use within Simcenter Flotherm in the following ways:

- Use as a detailed component model and, if necessary, adjust the geometry or attributes manually for custom packaging purposes.

- Add the component to a Simcenter Flotherm library.

- Automatically calibrate the model using data from Simcenter Micred T3STER hardware measurement.

- Create a BCI-ROM reduced order model in output types such as 3D CFD ready embeddable BCI-ROM format, fast electro-thermal circuit simulation VHDL-AMS format, system modeling (FMU format) or even as a thermal netlist.

- Create a two-resistor (2R) or DELPHI model using Command Center (scroll down for more information on this)

For engineers employing automation, please note that you can an also leverage Floscript to automate Simcenter Flotherm Pack Module operations.

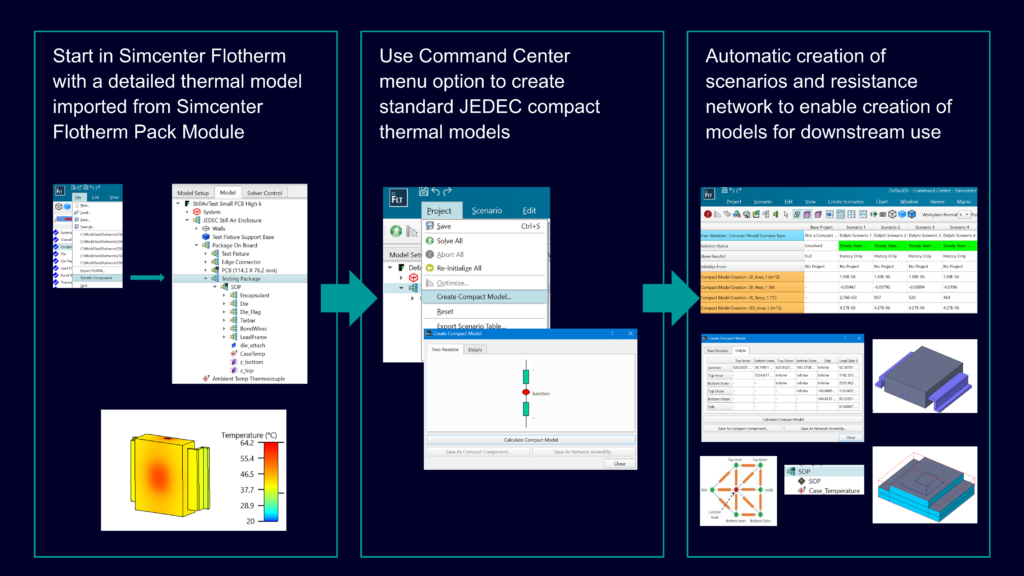

Create 2R and DELPHI compact thermal models in Simcenter Flotherm 2504

With your detailed thermal model in Simcenter Flotherm 2504 from Simcenter Flotherm Pack Module, you can leverage Command Center functionality to create 2R and Delphi Compact Thermal Models.

This is a straightforward procedure of starting a project, transferring in the detailed model, selecting the type of model required, and clicking “calculate compact model”. Command Center will automatically set up and solve the appropriate environments as defined in JEDEC standards.

After solution results are displayed in property sheet and the model is available for export as a Compact component or Network assembly type.

How to request a license of Simcenter Flotherm Pack Module

If you are a customer of the online Simcenter Flotherm Pack software that is a SaaS tool, please raise a support request on Support Center to get your license of Simcenter Flotherm Pack Module and for advice on downloading your existing models.

If you are interested in Simcenter Flotherm Pack Module as a new user, to enhance your use of Simcenter Flotherm, please speak to your account contact or reseller, or contact us.

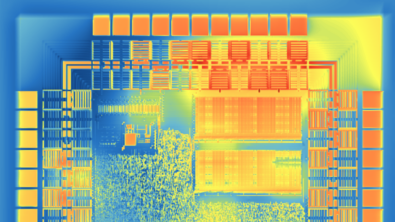

Humidity prediction in electronics – harsh environments to data center operations

Predicting humidity alongside electronics thermal management studies is useful for ensuring reliability. Whether for avionics, electronics in harsh environments such as an offshore wind turbine enclosure, through to ensuring reliable operation of datacenters or medical devices, there are guidelines for ranges of suitable humidity levels to avoid failures. These are available from professional organizations and in applicable industry standards.

The aims of simulation studies may be to avoid higher humidity conditions indicating condensation onset risks during operation, or to avoid low humidity levels that may lead to electrical failures e.g electrostatic discharge in data centers. Ensuring stable target ranges of operation is advantageous. You can now evaluate humidity and species concentrations values in Simcenter Flotherm 2504 for both steady state and transient analysis.

Concentration and humidity simulation in Simcenter Flotherm 2504

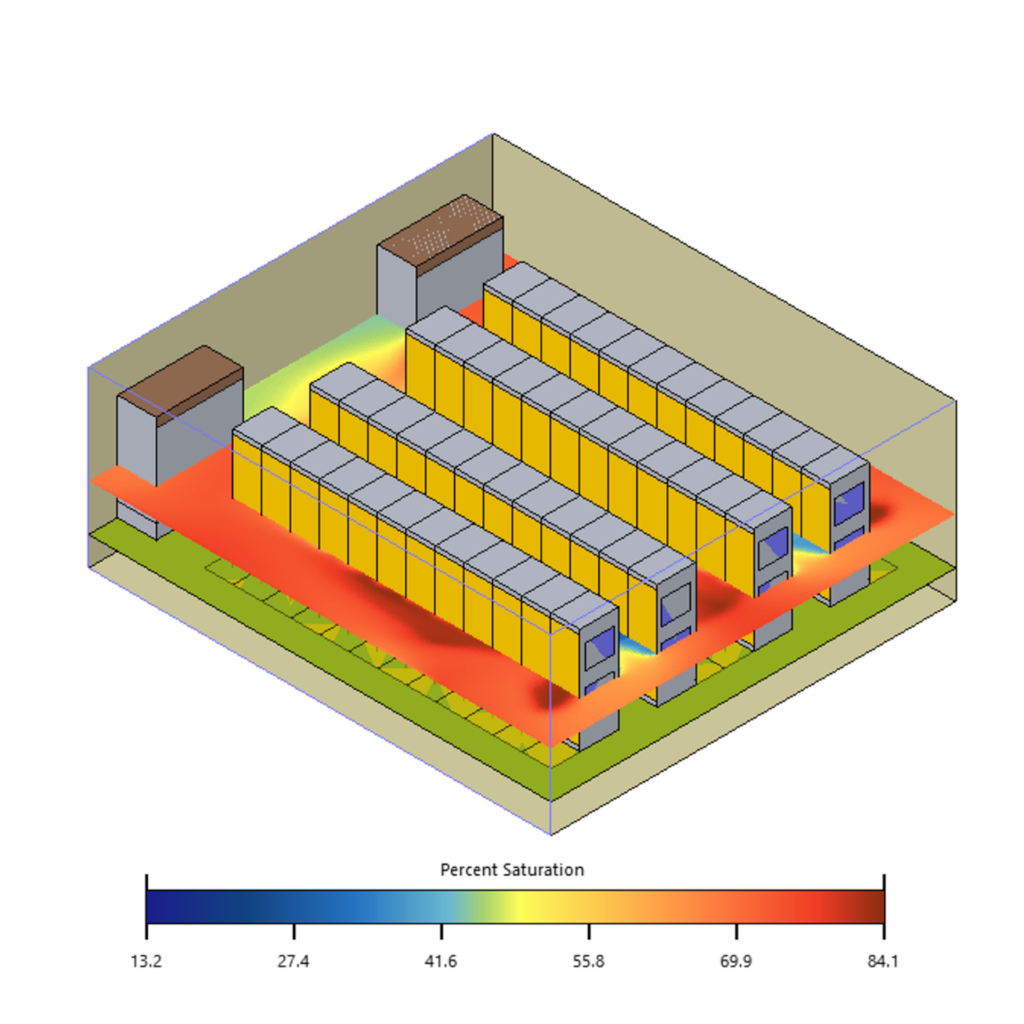

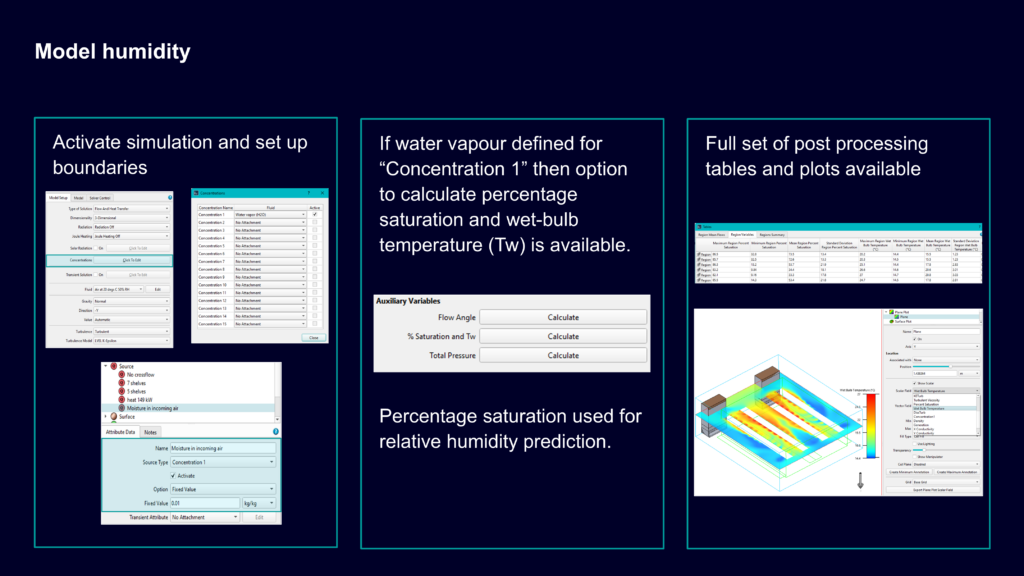

In Simcenter Flotherm 2504, a solution has been implemented to you to evaluate species concentration with special treatment of water vapor using post processing techniques to calculate wet bulb temperature and percentage saturation.

How do you set up a humidity study? In model set up, you select options for concentrations and for humidity studies, you simply set water as concentration 1. You then select settings for ambient, sources, and configure results outputs for additional variables for desired concentration parameters. In this way, post solution percentage saturation and wet bulb temperature are available to select under the auxiliary variables section in Model Setup after solution in post processing, which allows you to generate plots and tables.

Below are examples of generated tables and plots for wet bulb temperature and humidity as a concentration in Simcenter Flotherm for a data center model. You can also output transient results.

You can also apply concentration modeling to systems evaluation such as fire suppression systems which utilize a combination of gases, such as nitrogen, argon, and carbon dioxide, to suppress fires without causing damage to the sensitive electronic equipment found in data centers

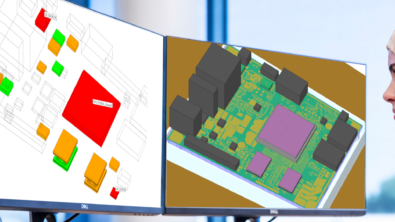

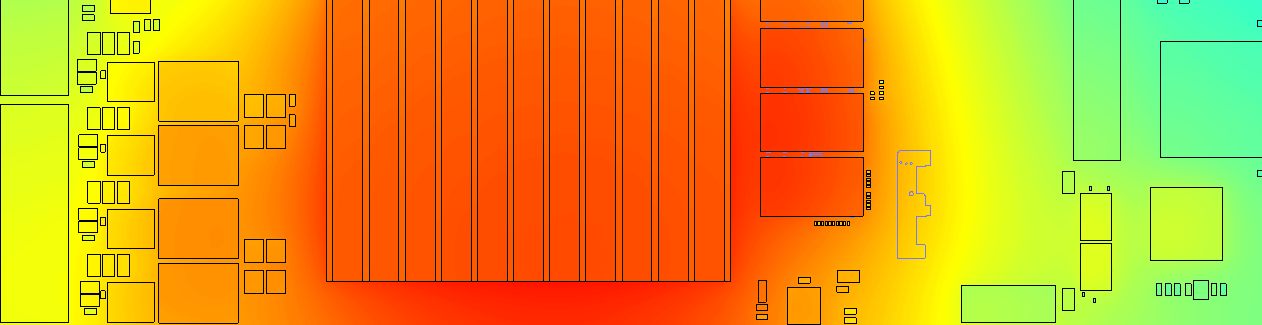

A quick note on PCB plots released in the prior Simcenter Flotherm 2410 release. A Simcenter Flotherm 2504 enhancement helps you go faster in quickly identifying components and key information to complement colored PCB Plots used for efficient pass/fail /marginal insights. There are now labels for PCB Components. Users can select key data and font size or utilize auto-sizing.

Download Simcenter Flotherm 2504 Now

Visit support center to download Simcenter Flotherm 2504 today and to read the release highlights documentation.