Vehicle battery packs – a new method to localize defects

The production of electric vehicles involves high costs. One of the main price drivers of Battery Electric Vehicles (BEV) is the price of the battery/battery pack itself. During production, it is important to verify the functionality. Indeed, during production at each step, the battery cells, modules, and packs undergo plenty of tests.

Pack/System validation consists of performance tests. Those tests involve charging of battery under certain profiles, dynamic stress test profiles, for example. Those cycling patterns of charging and discharging are application driven. Certain metrics will show whether the pack/system is functional or whether it doesn’t pass the test.

This article shows how Simcenter Sound Camera can be efficiently used to localize electric arcs and therefore help to repair battery packs.

Noise and Electric Arcs

One might tend to say that electrics and acoustics do not have a lot in common. But in BEV development this is less and less the case. Here we make use of the fact that an electric arc creates noise.

Now, what does this have to do with Battery Testing? For that, we are still missing one piece of the puzzle. A defective connection between battery cells will create an electric arc when the battery pack is tested. The electric arc creates noise, and the noise is located with the Simcenter Sound Camera.

How to Localize Electric Arcs in Battery Packs

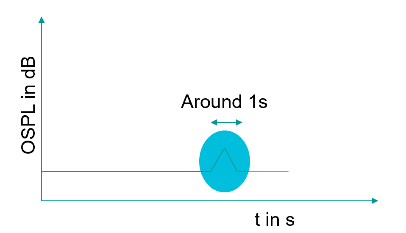

In practice, we will identify a peak in the Overall Sound Pressure Level (OSPL) when the electric arc appears, see below. But this is not all, the Simcenter Sound Camera can localize the position.

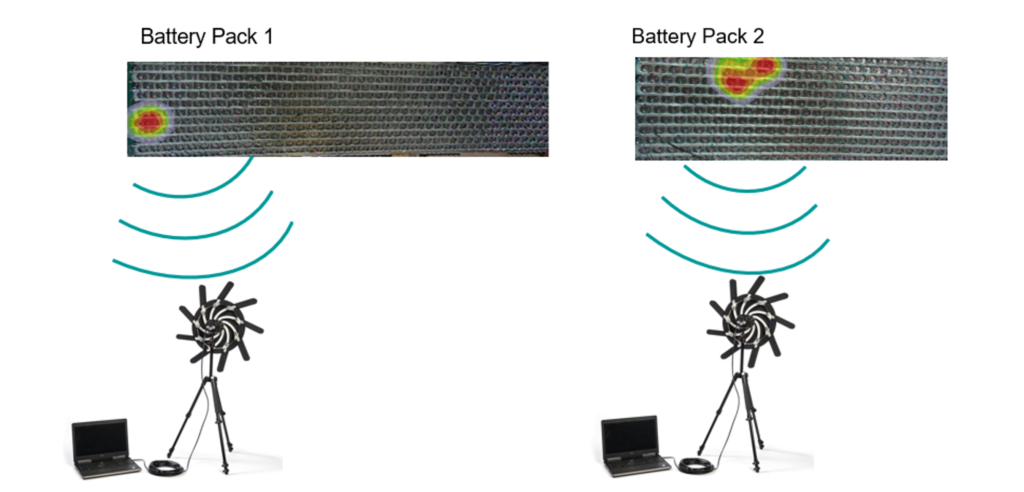

An electric arc is a transient event that takes a bit less than a second. Indeed, the noise source can be already seen in real-time during measurement. By using unique techniques of the Simcenter Sound Camera software, such as Bayesian focusing, the localization of the defect cell is exact. The defect is precisely identified. The sound camera hologram will show the defect location with a red dot. Below, we show two application examples, where the defect connection has been located.

We have seen how the Simcenter Sound Camera can be used to localize defect connections on the battery cell level in battery packs. Based on this information, the battery can be repaired and is then ready to be reused. This is an efficient way to save money if you ask me!

If you want to know more about Simcenter Sound Camera, click on this link.

If you want to know more about localizing defects on your battery pack, please contact us.