We didn’t start the fire. Battery thermal runaway chemistry simulation to fight the origins of disaster

Don’t try this at home – unless you’re simulating it!

A wise man once said:

Don’t put Li-Ion batteries in an oven or smash a nail into them.

by a wise man

Ok it wasn’t a wise man, it was me. But still, I would say this is general life-advice one should adhere to. Unless of course you are working in a lab investigating the thermal runaway behavior of batteries. These are essential tests to understand how batteries respond to overheating (i.e. “stick it in an oven and see what happens”) or impact damage (i.e. a “let’s hammer a nail into this thing”). Before we talk about such tests in more detail, let’s take a quick step back and recap on what Thermal Runaway is and why it’s important.

Thermal Runaway: a recap

Thermal runaway of batteries is a dangerous phenomenon where the battery cell overheats uncontrollably. A self-sustaining feedback loop occurs where the battery receives a certain amount of heating, and if left unaddressed, this in turn triggers a series of chemical reactions inside the battery cell.

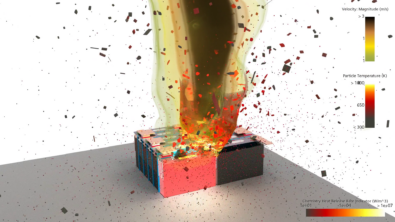

These reactions release even more heat and gases, which can result in huge pressure build up inside the battery. Extremely hot (over 1000oC!) and combustible venting gases are then emitted from the battery cell. When these gases ignite, fire spreads to other battery cells and catastrophic damage can occur to an electric vehicle, property and of course presents a high risk to life.

Look at this short video which shows the violent nature of a thermal runaway event:

It should be clear that these scenarios should be avoided, and battery systems designed to ensure safe operation if a thermal runaway event occurs. Indeed there are now various national and international regulations that cell makers and electric vehicle manufacturers must adhere to.

Time to test? – Accelerated rate calorimetry (ARC)

The most intuitive way to understand the behavior of batteries as they undergo a thermal runaway event is to replicate the causes of thermal runaway and see how the battery behaves. In the case of overheating, a common methodology to understand the heat release of the battery is an accelerated rate calorimetry (“ARC”) test. These tests provide clear insights but come with some issues: primarily that the tests themselves are expensive, require access to test facilities and require a physical prototype of the battery cell! Of course, this is where simulation can fit in and allow for rapid design iterations early in the design cycle, with safety in mind.

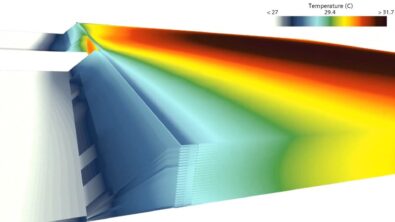

Simcenter STAR-CCM+ already has a wide range of models and functionalities for battery modelling and battery safety, from the 3D cell design right through to the full battery pack and thermal propagation during a runaway event:

In our 2502 release, we are adding another level of functionality – primarily the ability to model detailed cell-level thermal runaway with our Homogeneous Multiphase Complex Chemistry (HMMC) model. Sounds like quite a mouthful so let me explain…

Thermal runaway chemistry – The devil is in the detail

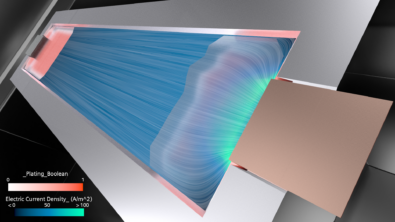

When we consider the inside of a battery cell then there are multiple solids (anode, cathode and separators), as well as liquid electrolyte. When thermal runaway reactions occur, these components can react and decompose to release flammable gases such as hydrogen and methane. This results in multiple phases all reacting with each other e.g multiphase.

To capture this complexity, we have developed a framework in which the early stages of a thermal runaway event can be modelled with detailed chemistry modelling. This allows designers to explicitly model the fundamental reactions that are triggered during a thermal runaway event. Reactions are considered as a homogenous mixture allowing for a simple and easy set up in conjunction with our mixture multiphase model. Additionally, all of this is built on top of our well-proven complex chemistry solver allowing for reactions to be easily defined using standard chemkin file import, and accounting for intra and inter-phase reactions. This provides a unique modelling functionality to deeply understand the behavior of batteries.

For example we can directly set up reactions for SEI decomposition / production, conductive salt decomposition, Hydrogen Fluoride production and Cathode decomposition, see example of imported reactions for thermal runaway test above.

Let’s get cookin’ – Heat-Wait-Seek

Armed with a new modelling tool, let’s apply it to the simulation of an ARC test and see how it performs. The ARC test involves an initial period of heating the battery called Heat-Wait-Seek (HWS) where the battery is gradually heated before waiting to see if exothermic reactions begin. When those reactions begin, no more heat is applied to the battery, and it is left to continue reacting / self-heating until the onset of thermal runaway.

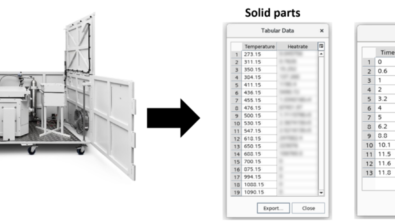

A great thing about having this physics functionality inside Simcenter STAR-CCM+, is that we can leverage the automation capabilities. The ARC test process can easily be implemented using Simulation Operations and Stages without any scripting. And the results are excellent:

As can be seen, our new HMMC model can accurately capture the onset of both the exothermic reaction and thermal runaway.

Being able to accurately capture this behavior allows for effective countermeasures or mitigation strategies such as heat shields to be implemented by engineers much earlier in the design process in a safe and cost-effective manner. For example, the predicted heat generation from this simulation can be used as an accurately calculated heat source directly in a larger pack level model, or the predicted vent gas compositions used for a further combustion analysis. An excellent example of how simulation is vital in the battery design cycle.

A final warning

That warm, fuzzy feeling you get when testing this in Simcenter STAR-CCM+ 2502 is likely NOT the start of a thermal runaway event, just the start of a safe, efficient and accurate design process.

Comments

Comments are closed.

Hi Liam,

Thank you for the post, gives an insight to Star CCM+’s capability to handle thermal runaway.

Wanted to ask, if we use Homogeneous Multiphase Complex Chemistry (HMMC) model, do we still need ARC test input data to setup the thermal runaway simulation?

Best regards,

Pranav