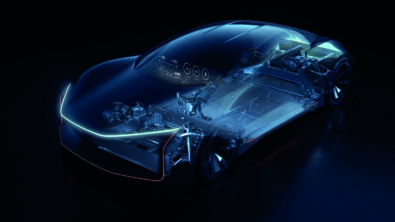

The future is virtual prototyping: Find out how Hyundai Mobis are enhancing their designs

Physical prototyping has long been standard in the automotive industry. However, shorter lead times and increased complexity have required manufacturers to adopt a different approach. In addition, the transition to electric vehicles means that there is no longer an internal combustion engine to mask some unwanted noise. As a result, designs must be optimized even further to eliminate even minor sounds or vibrations to deliver the quality that customers expect.

This is why many companies are turning to simulation. It allows them to cope with the demands of 21st-century automotive design while developing new vehicles faster than ever.

But that’s not all. Keep reading to see how adopting the latest simulation techniques can also inspire innovation and lead to designs that would never have previously been considered.

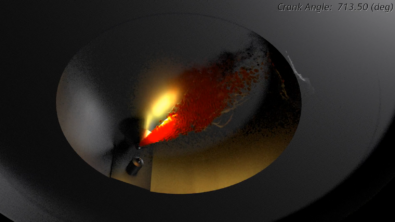

Acoustic simulation

Hyundai Mobis develops a range of systems for automotive manufacturers, including steering and electric drive transmissions. To address the modern challenges of designing these critical components, the company has adopted a range of simulation tools.

NVH research engineer Ho-Gil Yoo explains that acoustic simulation is key to minimizing unwanted noise. “Transmission errors are a leading cause of poor NVH performance, but most gear systems engineering tools are quasi-static, making this hard to identify.”

The answer to this is to use the time-domain simulation capabilities of Simcenter 3D Motion to accurately capture the dynamic characteristics of the electric drivetrain and optimize designs.

That’s not as simple as it might sound. In fact, this required a significant amount of time to create the necessary complex models. But once the hard work was done, they could reap the benefits. “Simcenter 3D makes it straightforward to synchronize structural acoustic analysis with motion models in one procedure,” says Ho-Gil. “We used the Simcenter Nastran structural solver to calculate the flexible bodies, then input these to the Simcenter 3D Motion model.”

Proven results

Simulation only has value if its accuracy can be proved. So, validating the results with previous test data was vital.

The first comparison revealed significant differences between the mode frequencies of testing and simulation. To address this, Ho-Gil initially imported the test results into Simcenter 3D Correlation. If this indicated that higher fidelity was necessary, he connected the model to Simcenter HEEDS. This automatically conducted simulations to find optimized results in a statistically efficient way, increasing the speed and accuracy in validation.

Ho-Gil is very happy with the results. “We found that Simcenter 3D Motion is very powerful for investigating systems at a deeper level,” he says. “It accurately mirrors physical test results to give us confidence in using simulation to improve our designs.”

Inspiring innovation

Simcenter HEEDS has been invaluable for speeding up the optimization and validation process, but it has also delivered further benefits. Ho-Gil explains that human design can be limited by too much realism. After all, it’s only natural for the human mind to automatically discard or not even consider ideas that seem impossible.

“The automated algorithm isn’t limited by these thoughts,” he says. “It simply looks for the best optimization, so it explores every possible configuration.”

Crucially, automation means that ideas that would previously have been too outlandish or time-consuming to investigate manually, can now be considered. This can lead to exciting innovations that would otherwise never have the opportunity to be realized.

The growing importance of simulation

Stories like this show just how important simulation already is for the automotive industry and how that importance will only going to continue to grow. Hyundai Mobis plans to extend its use of simulation to other vehicle systems, so expect to see the company deliver even better optimized products in even shorter timescales in the future.

To discover more about Hyundai Mobis’ use of Simcenter, check out the full case study.

To learn more about the future of prototyping, read Eric Sorber’s blog where he reviews a masterclass series on component-based transfer path analysis and virtual prototyping.