What’s new in Simcenter FLOEFD 2312? | CAD-embedded CFD simulation

The new Simcenter FLOEFD 2312 software release enhances CAD-embedded CFD to shorten pre-processing activities, accelerate electronics thermal design workflows, while adding new capabilities for structural analysis, and an improved Application Programming Interface (API) for simulation automation. Read on below for information on these and new features such as faster CFD meshing of convergent geometry, improved speed for Smart PCB thermal modeling, PCB reflow oven modeling, and more.

Model the complexity

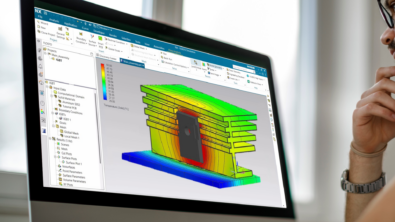

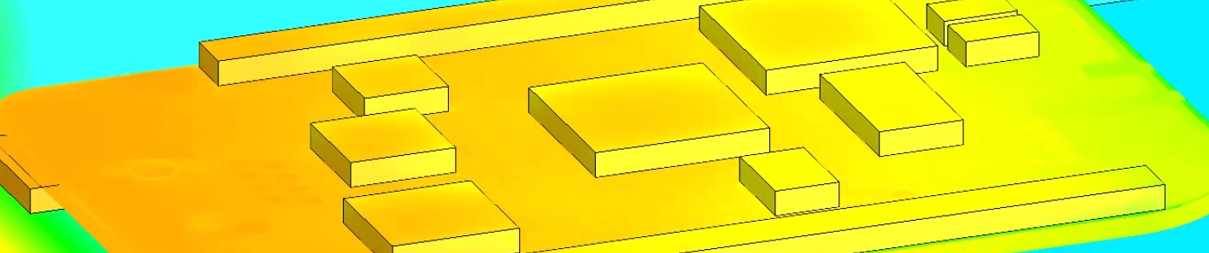

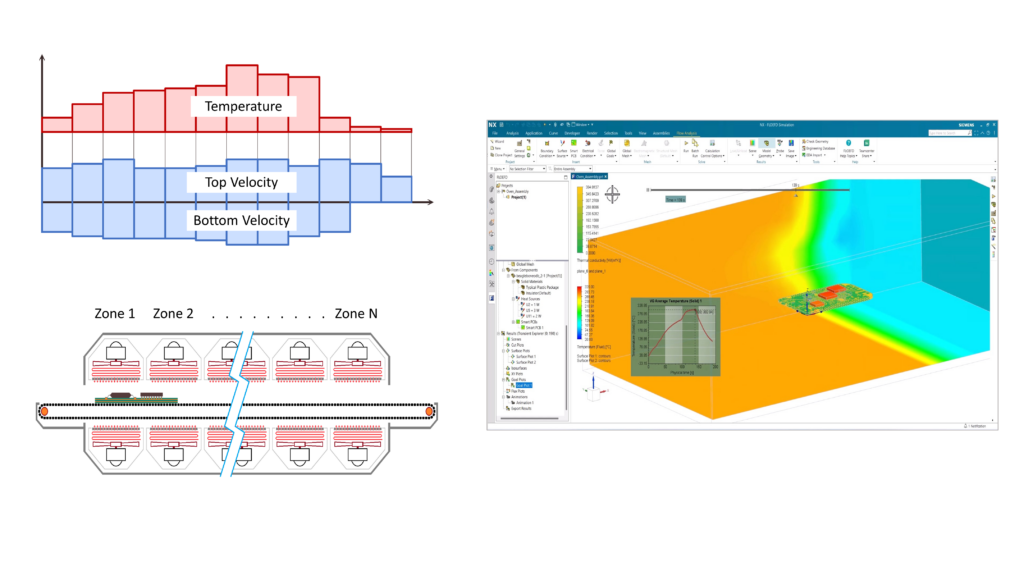

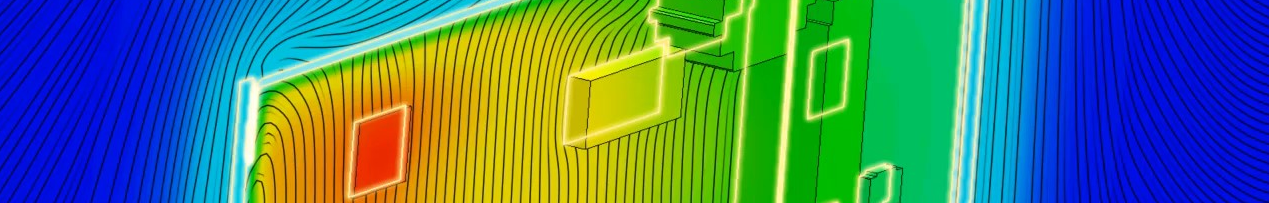

PCB reflow oven thermal process simulation

IIn a PCB reflow oven, as a PCB moves along a conveyor it is exposed to heating and cooling zones with different air flow velocity and temperature parameters.

Values for these zones’ parameters as well as the conveyer speed are to be chosen by the PCB customer prior to manufacturing. The operation design challenge is to increase the conveyer speed for highest throughput while meeting thermal constraints to avoid damage to PCB mounted components. Experimental approaches to determine these parameters are expensive because failed attempts lead to lost time, reduced product quality or low throughput. Simulation of the reflow oven process to optimize operational parameters prior to physical tests is very advantageous.

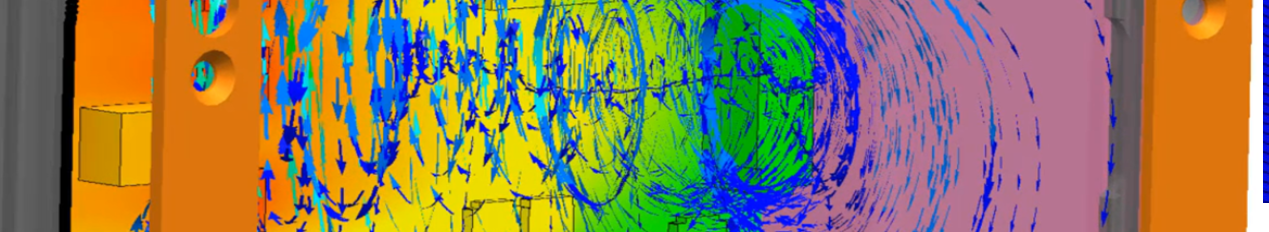

In Simcenter FLOEFD 2312, a project template has been added so you can create and modify a PCB reflow oven simulation as a transient study to reflect conditions as a board moves through an oven. The template leverages the project parameters functionality in Simcenter FLOEFD and the new EFDAPI automation capabilities is used to modify parameters. The approach simulates the reflow process inside a small volume space around the PCB with moving flow boundary conditions instead of simulating the real oven with moving bodies.

Watch this video to see indicative steps in setting up and running a PCB reflow oven thermal process simulation.

Note: Advanced usage of this new capability combines Simcenter FLOEFD and the Simcenter HEEDS design exploration and simulation automation tool for extensive optimization studies.

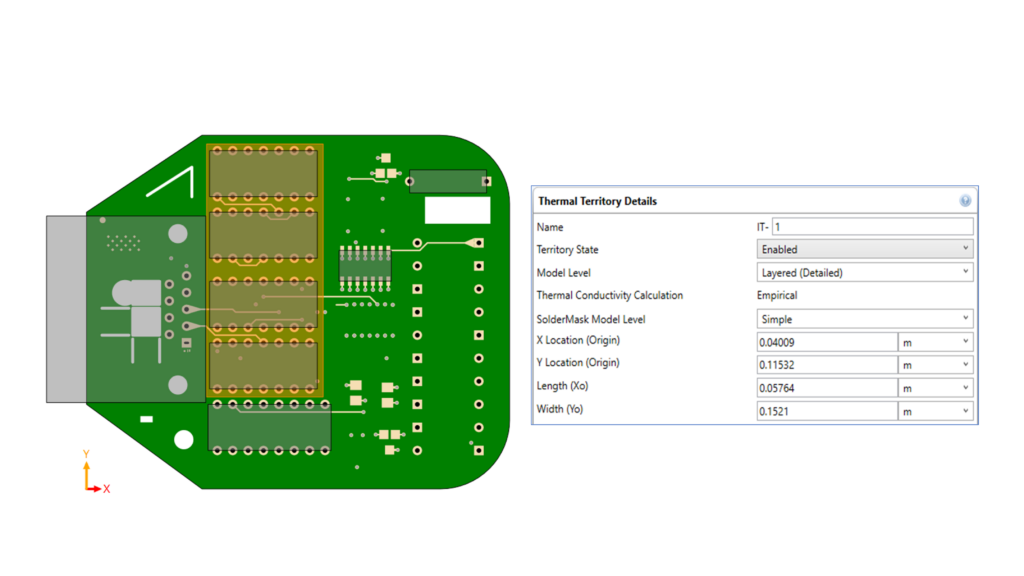

PCB thermal analysis: EDA Bridge Standalone Thermal Territories

Localized PCB thermal modeling fidelity provides advantage of accuracy for modeling copper and layers beneath critical components. This computational efficient solution remains a good alternative to explicitly modeling applied to a whole board. Previously in Simcenter FLOEFD, thermal territories, were defined centered on a single component and aspect ratio defined. Now in Simcenter FLOEFD 2312, users can specify a standalone Thermal Territory which can be placed anywhere independently on a PCB and then set it’s aspect ratio. This enables localized modeling fidelity to be set to encompass areas with groups of components more easily.

Users define the following definitions and then select the modeling level:

1) Location (X and Y)

2) Size (Length and Width)

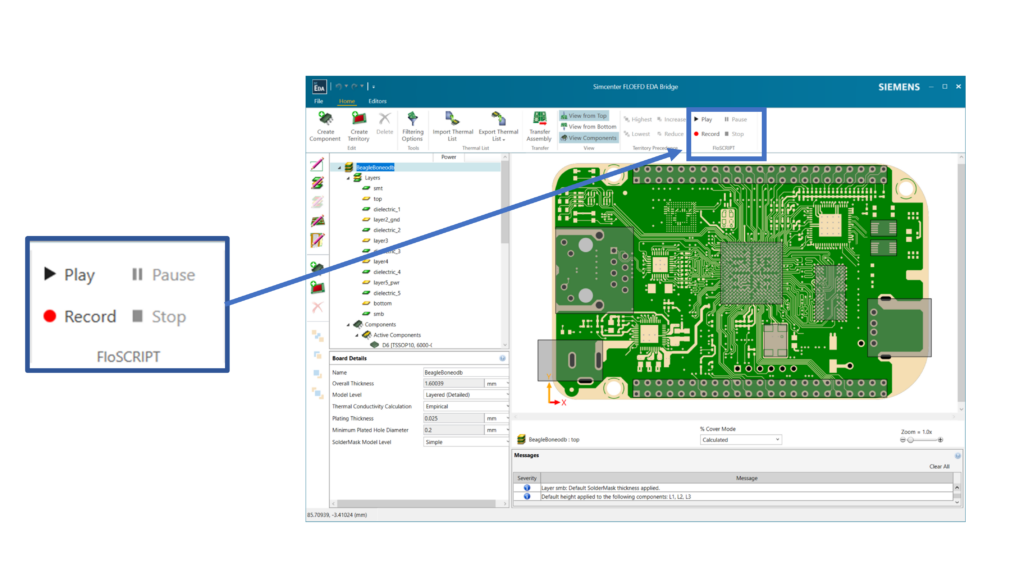

PCB thermal analysis: EDA Bridge scripting

Users can now record and playback scripts that capture the workflow in the main EDA Bridge window where you process imported ECAD data. Functionality that can be recorded and run include includes actions like changing the modeling level of the board and creating thermal territories. Scripting will be enhanced in subsequent releases from Simcenter FLOEFD 2312 onward

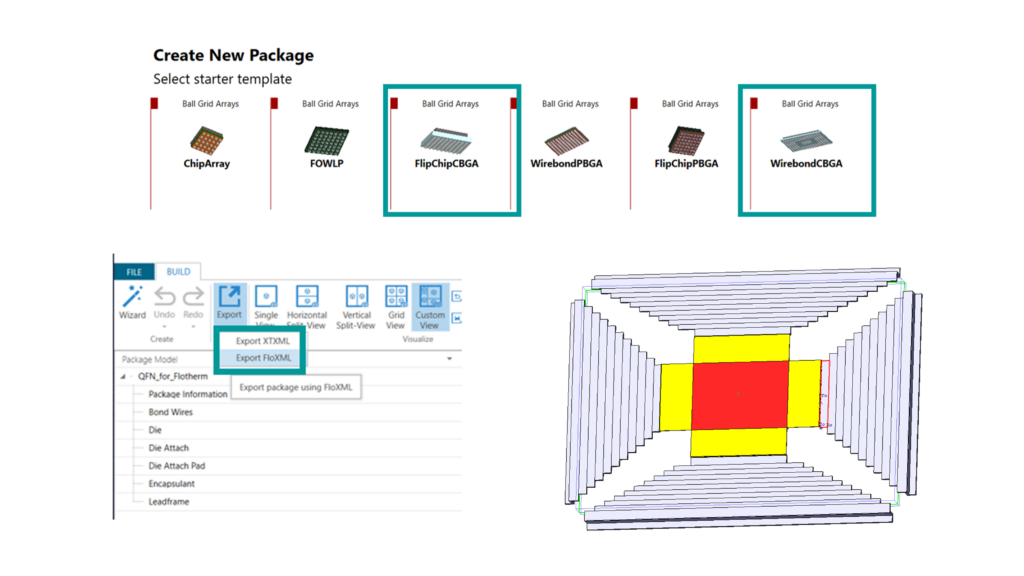

Electronics component thermal modeling: Package Creator Updates

What is Package Creator? the existing Package Creator utility in Simcenter FLOEFD enables engineers to create 3D CAD geometry based IC package thermal models quickly and easily in minutes from a list of templates guides for common package families. These detailed models can then be used in electronics cooling simulation studies in Simcenter FLOEFD.

At Simcenter FLOEFD 2312, the following updates have been implemented in Package Creator.

– 2 new IC package starter templates: Flip Chip CBGA and Wirebond CBGA.

– Creation of Simcenter Flotherm-ready detailed models you can export to share with other organizations

Structural analysis enhancements in Simcenter FLOEFD 2312

Structural: Mesh Boolean Operation for handling complex geometry, easily

Certain complex geometry models can sometimes create issues whereby Boolean operations simply cannot be completed using CAD Boolean processes or in other cases pre-processor Boolean approaches can be time intensive. A new enhanced structural mesh generator and geometry preparation now supports Mesh Boolean for structural analysis meshing. This provides a solution to enable engineers to create mesh faster, automatically, even for extremely complex geometry.

Structural: Non-linear materials

Enhancement has been made to the Engineering Database to be able to set engineering stress-strain curves for solid materials in Simcenter FLOEFD, to combine with leveraging the existing capabilities of Simcenter 3D Nastran solver to run an analysis. As a reminder, the Simcenter NASTRAN non-linear solver connection for Simcenter FLOEFD was introduced in the 2306 version.

Structural: Large strain modeling

A new new option is now selectable for large strains which activates the corresponding option of Simcenter 3D non-linear Nastran solver. Simcenter FLOEFD 2312 now allows re-calculation of engineering stress-strain to true stress-strain. This provides more accurate results for analysis where large values of strains are reached.

Structural: General contacts improved

Using Simcenter FLOEFD and leveraging the Simcenter 3D non-linear Nastran solver while modeling general type of contacts now means contacts can appear and disappear during the iterative calculation process as a result of body deformation. In previous versions of FLOEFD contacts were created before the solver starts and could not be changed, appear or disappear for deformed bodies.

Go faster

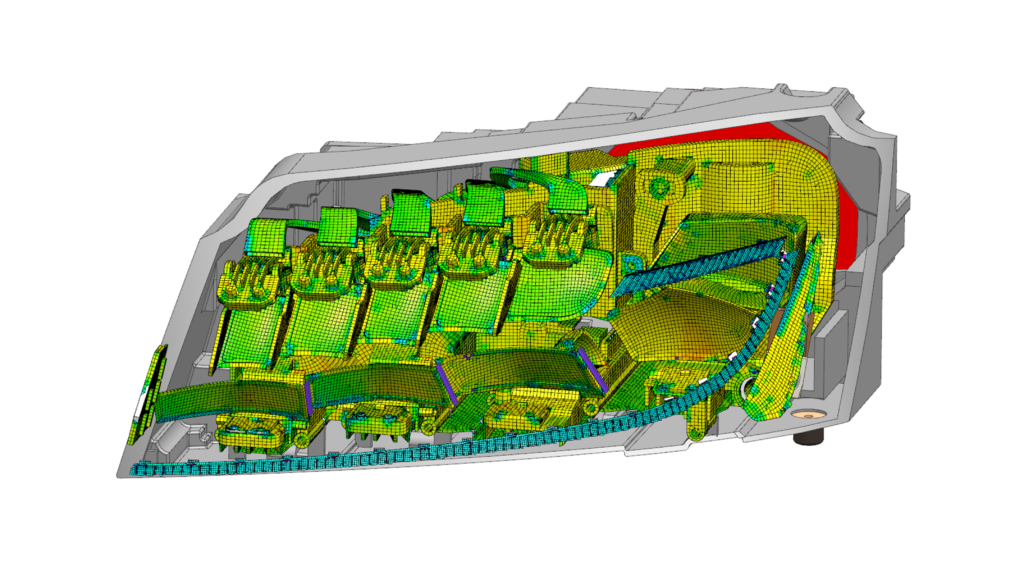

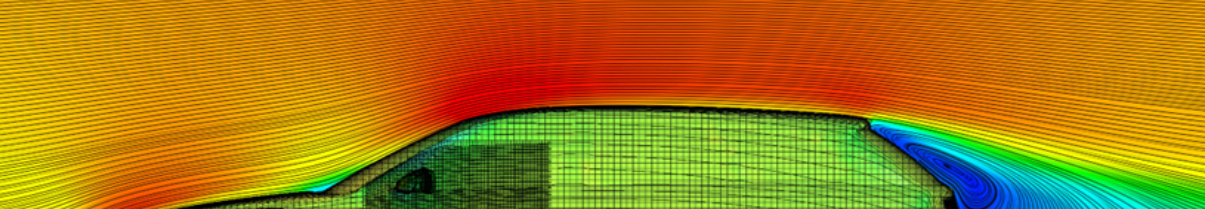

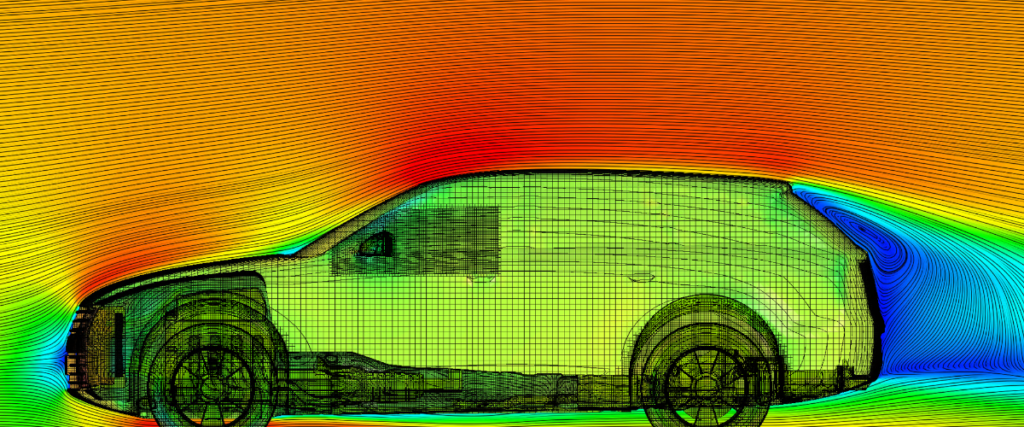

Faster CFD meshing for convergent, faceted, and STL geometries

Mesh generation is now accelerated for convergent, faceted, and STL geometries geometries so it is as efficient as mesh generation for parametric solid geometry. An example below being 10 x faster for a vehicle model that was converted from STL data as a convergent body for an external aerodynamics study.

Simcenter FLOEFD mesh size 62 million cells.

Comparing meshing time:

In prior version 2306 = 2 hours

Now in version 2312 = 12 minutes

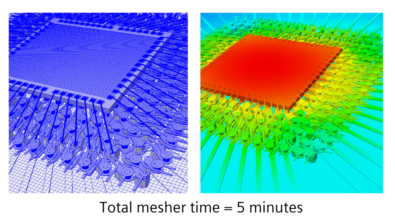

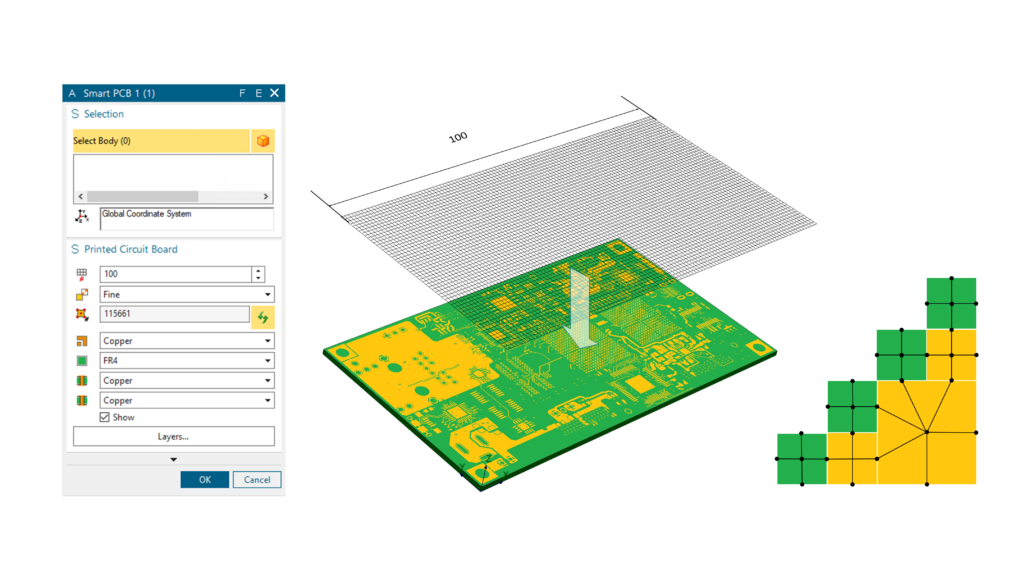

Smart PCB thermal modeling – fidelity and speed improvements

The Smart PCB feature is one of several options for PCB thermal modeling. It is a sophisticated approach to efficiently capture the detailed material distribution of a PCB without the added computational resource and time penalties typically required to model the PCB explicitly. It does this by using a network assembly approach , whereby a voxel-style grid based on the images of each PCB layer in imported EDA data is generated.

In Simcenter FLOEFD 2312, the solver speed for the Smart PCB calculation has been optimized significantly so you can better leverage this modeling option for high accuracy PCB thermal analysis that is even faster. Additionally, this solver speed up has allowed for alteration of the the default settings for the number of tiles on a PCB. The settings now go from default 100 to 300 which in turn produces a more accurate solution, especially when using the “Fine” modeling option.

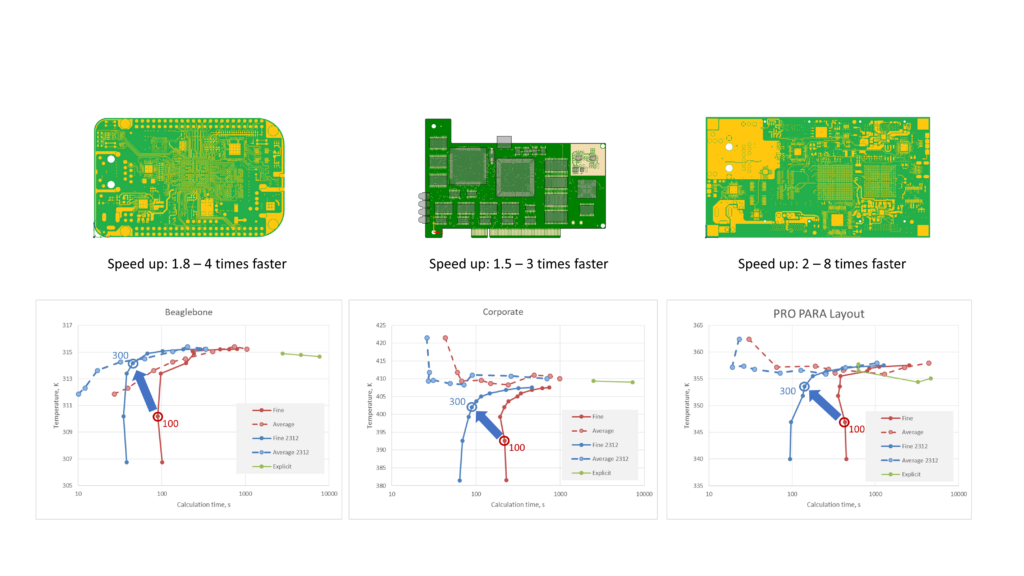

Below – results for solutions times for 3 different models are shown comparing fine and averaging settings for number of tiles set, at both Simcenter FLOEFD 2312 and the prior version 2306. The illustrated solution times show a speed up by a factor of 1.5 times to 8 times is achievable which is advantageous to turn around accurate PCB thermal studies in less time. Clearly the PCB size and complexity is a factor in the speed up possible as would be expected. You can also observe the significant shorter solution time for a Smart PCB to solve compared to an explicit PCB model.

Explore the possibilities

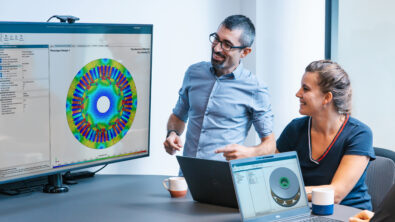

Automation – EFDAPI is an improved API to accelerate your process

The new EFDAPI has been introduced and now covers all existing features and parameters in Simcenter FLOEFD. The enhanced functionality and improved ease of use enables engineers to take advantage of automation to shorten simulation workflow.

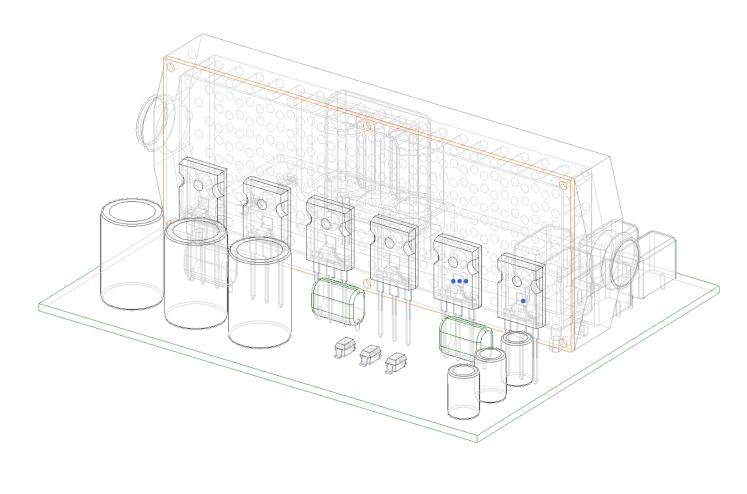

Consider the case of automating the electronics cooling simulation of a Boost Converter

The following short video below illustrates automation of the following steps

- Run CAD and open model

- Create FLOEFD project

- Set up all boundary conditions and simulation settings

- Run simulation and post-process the results

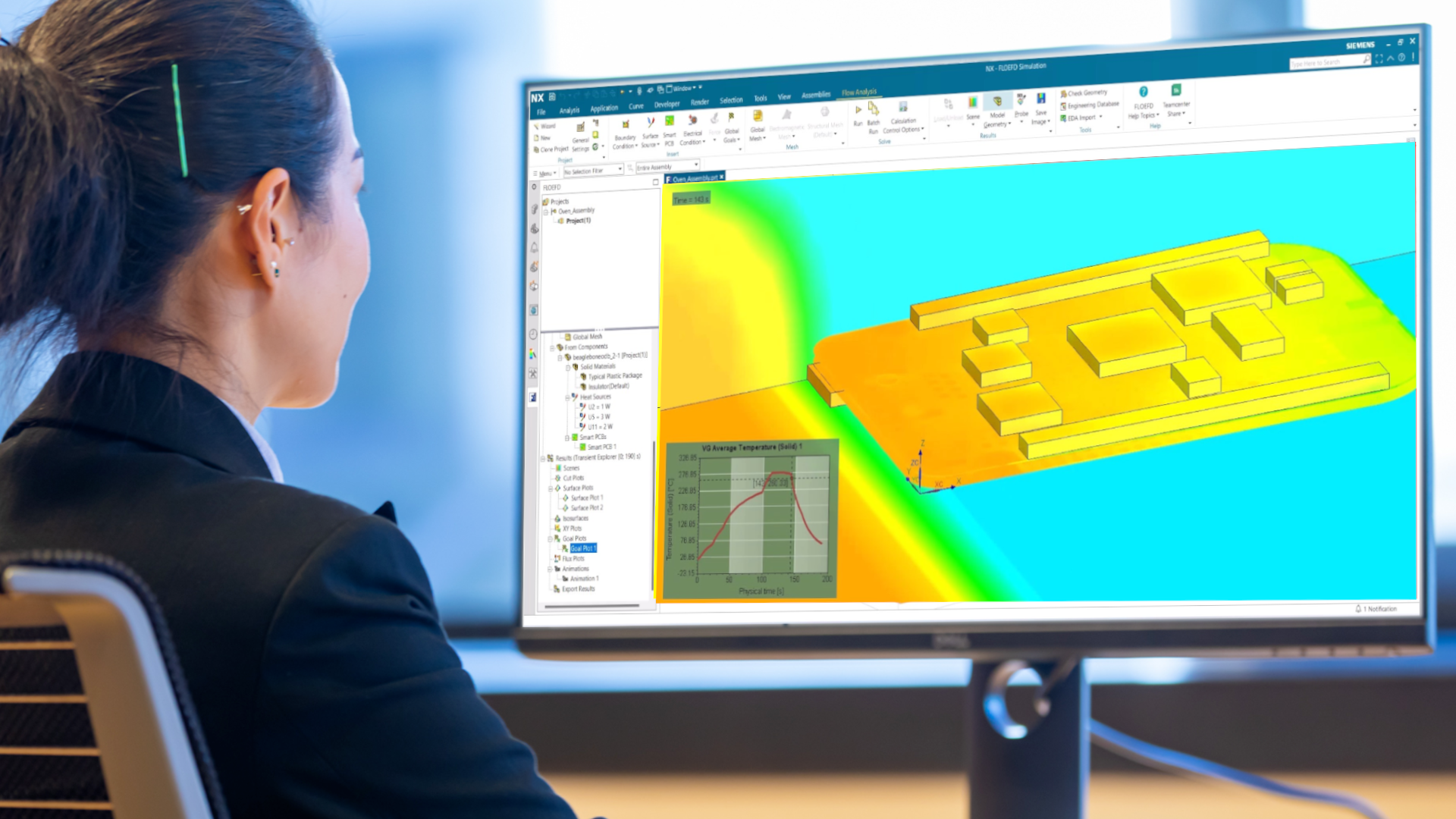

Batch results post-processing without opening CAD

Typically using Simcenter FLOEFD CAD embedded CFD in normal operation, a project needs to be opened and results needs to be loaded to create resulting images and spreadsheets. Automatically creating them after calculation uses the “Batch Results Processing” tool. Now, batch results processing is possible without opening CAD.

You can now:

– use Command-Line Run Export which generates necessary files for batch results processing on Windows or Linux machines

– run the solver on remote server and batch process results on server at end of a solve automatically without copying files back to client

In this short video below the steps are illustrated:

Stay Integrated

SCD5 export Support to Simcenter 3D

Simcenter FLOEFD fields can now be exported in the SCD5 format of Simcenter 3D. This results in a binary file for data transfer from FLOEFD to Simcenter 3D. This means that there can be a significant filesize advantage using the binary SCD5 format. This helps for transfering fields from a thermal analysis to a thermo-mechanical stress analysis in Simcenter 3D.

You can export steady state or transient pressure and temperature fields to a CGNS file using SCD5 mesh file as input data.

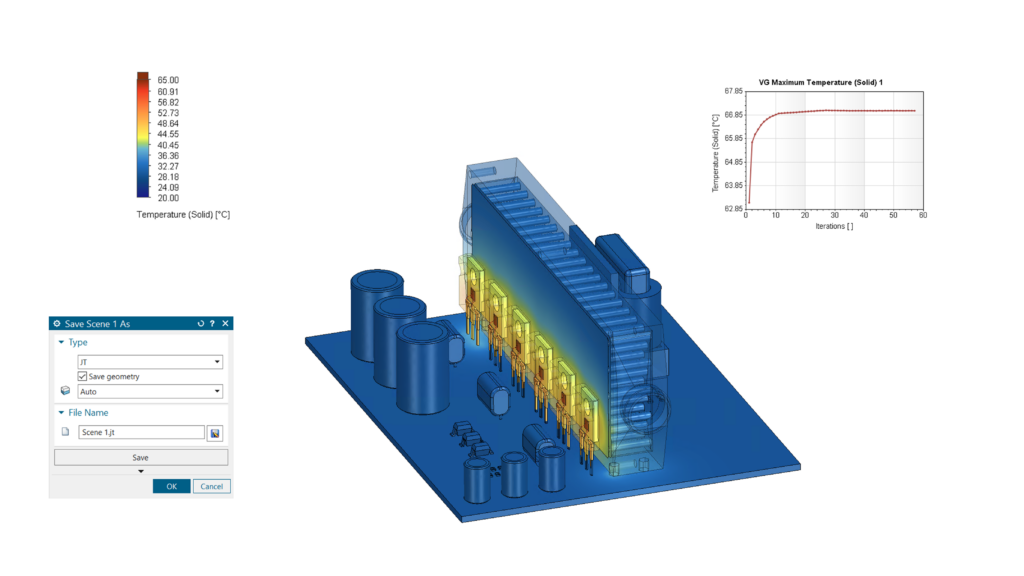

Teamcenter Viewer Support. JT format export

Simcenter FLOEFD scene files can now be saved in JT format. This enables viewing of simulation results from Teamcenter using its viewer (which uses JT format)

For clients: downloading Simcenter FLOEFD 2312

You can download Simcenter FLOEFD 2312 in your CAD variant version from Siemens Support Center. Click here to go to the download section for Simcenter FLOEFD for NX and also for Creo, CATIA V5 and other versions.