Simcenter E-Machine Design 2512: Release highlights

The latest release of Simcenter E-Machine Design 2512 brings a suite of powerful enhancements designed to tackle real-world engineering challenges in electric machine design and simulation. Here’s what’s new and why it matters for your workflow.

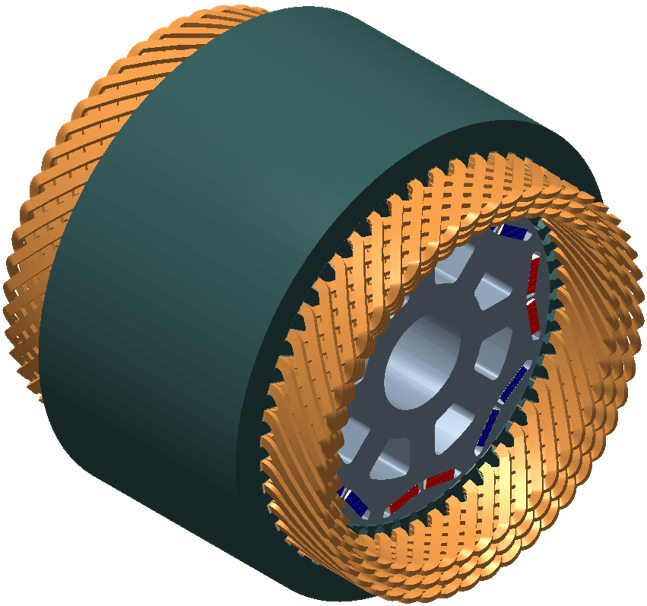

1. Accurate hairpin winding losses

Why it matters:

As electric machines evolve, hairpin windings—especially those with larger solid conductors—face significant AC losses at higher frequencies. These losses, driven by skin and proximity effects, can impact efficiency and thermal performance.

What’s new:

- Explicit modeling of individual conductors in 2D FEA for precise loss calculations.

- Automatic calibration of AC loss models using simulation data.

- Fast estimation of AC losses for non-transient experiments (PWM, efficiency maps).

- Supports both automatic and user-driven hairpin winding configurations, with up to 12 layers and custom connectivity tables.

Impact:

Engineers can now model the complexity of hairpin windings with accuracy, leading to better predictions of losses, efficiency and thermal behavior

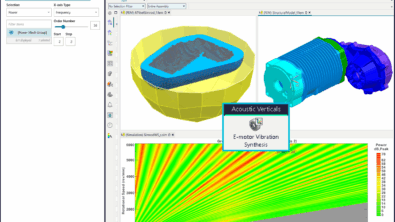

2. Early NVH assessment with Airgap Flux Density Export

Why it matters:

Noise, vibration, and harshness (NVH) are critical for electric motor design, especially in automotive and industrial applications. Faster methods to predict NVH accurately are key to speed time-to-market.

What’s new:

- Automated extraction of reduced-order models (ROMs) for NVH analysis based on airgap flux densities.

- ROMs can be reused across different currents, angles, and rotor positions.

- Parallel computing reduces extraction time.

- Export compatibility with Simcenter 3D and soon with Simcenter Amesim eNoiseApp for integrated NVH workflows.

Impact:

This enables early and efficient NVH assessments with the vibration sysnthesis method, helping teams address potential issues before physical prototyping. Engineers can now generate a single electromagnetic ROM for a specific design and reduce the overall amount of data transfer and data generation time.

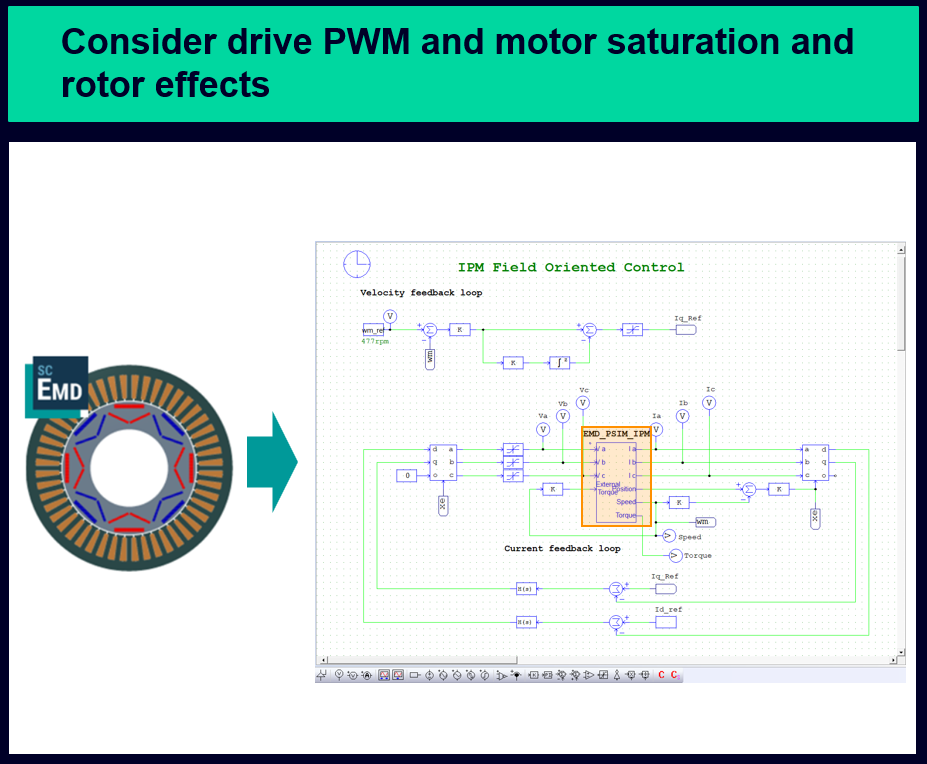

3. Export of E-Motor ROMs to Altair PSIM

Why it matters:

Drive system analysis requires realistic modeling of the interaction between the e-motor and the power electronics module, including Pulse Width Modulation (PWM) effects, motor saturation, and rotor-stator interactions.

What’s new:

- Direct export of e-motor ROMs to PSIM for advanced drive system simulations.

- Higher accuracy with realistic PWM and saturation effects.

- Efficient coupling via ROMs, avoiding the need for co-simulation.

- Support for synchronous machines (SM) module.

Impact:

Engineers can now integrate their e-motor models from E-machine Design in PSIM and leverage PSIM’s specialized power electronics and control libraries for more accurate and integrated drive system analysis.

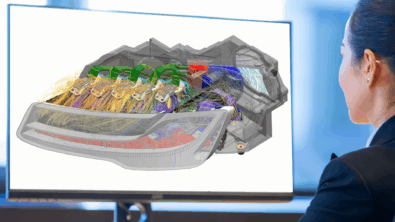

4. Seamless transfer of E-motor models across Simcenter

Why it matters:

Collaboration between different engineering disciplines is often hampered by manual model transfer and rework. Engineers typically need to model again their e-motor

What’s new:

- Improved automated transfer of 3D e-motor designs to Simcenter 3D and STAR-CCM+.

- Automatic creation of 3D models ready for meshing and solving in a few clicks.

- Simplifies modeling for non-EMAG experts and eases data exchange between teams.

- Supports a wider range of machine types: axial flux, radial flux (synchronous, induction, switched reluctance, commutator).

Impact:

This streamlines the workflow from initial design to detailed analysis, saving time and reducing errors. Allowing teams to validate their designs by running more accurate simulations that used to be prohibitive.

Simcenter E-Machine Design 2512 out now!

Simcenter E-Machine Design 2512 delivers targeted innovations that address the complexity of modern electric machine engineering. From more accurate loss modeling and early NVH assessment to integrated drive system analysis and seamless model transfer, this release empowers engineers to design, simulate, and optimize with confidence.

Ready to explore these features? Dive into the new release and see how Simcenter E-Machine Design can elevate your simulation workflow, or check out what is in the latest Simcenter 3D release