Optimizing vessel propulsion power: a critical strategy for maritime sustainability

In today’s rapidly evolving maritime industry, the quest for sustainable shipping has become more urgent than ever. As we navigate through 2025, the shipping sector faces mounting pressure to reduce its environmental footprint while maintaining operational efficiency. Optimizing propulsion power has emerged as a crucial solution in this challenging landscape.

Regulatory evolution and compliance

The maritime industry has witnessed a significant transformation in recent years, driven by increasingly stringent environmental regulations. The International Maritime Organization’s (IMO) 2025 regulations, coupled with regional environmental policies, have created a new operating paradigm for vessel owners and operators. Additionally, the implementation of carbon pricing mechanisms has made it imperative for shipping companies to optimize their operations for both environmental and economic sustainability.

Technological advancements in system simulation

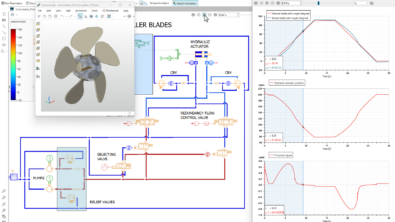

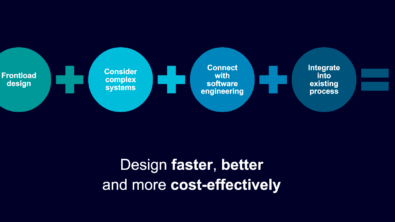

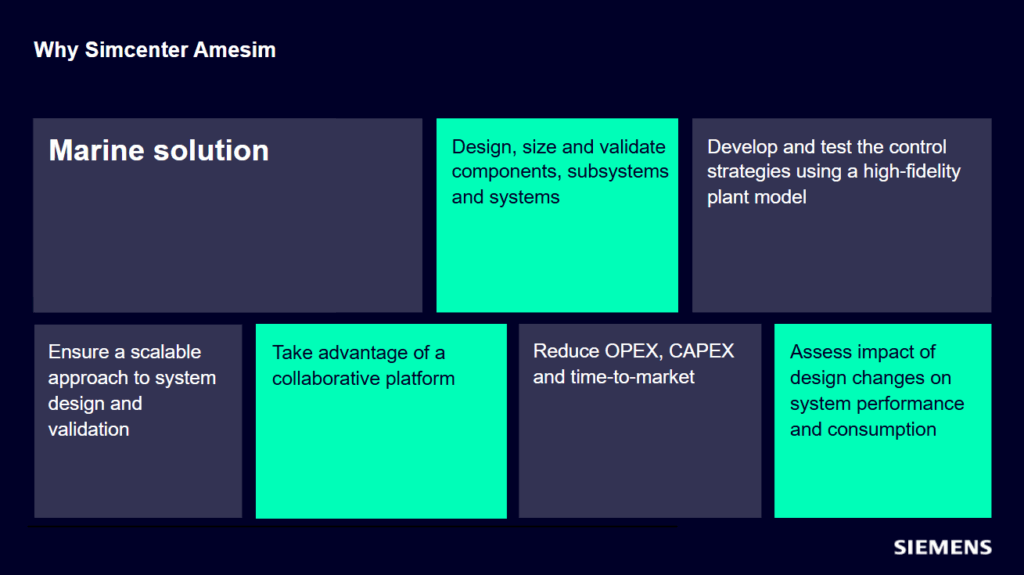

System simulation technology has made remarkable strides, revolutionizing how we approach vessel optimization. Today’s solutions incorporate advanced artificial intelligence and machine learning capabilities, enabling unprecedented levels of precision in propulsion system design and operation. The integration of digital twin technology allows for real-time optimization and adjustment, while cloud-based collaborative platforms have made it possible for teams across the globe to work together on complex optimization projects.

The economic landscape of 2025 presents both challenges and opportunities. With fuel costs remaining volatile and competition from alternative shipping technologies intensifying, vessel operators must find innovative ways to maintain profitability. Modern optimization strategies have evolved to meet these challenges head-on. Hybrid propulsion systems, enhanced by smart power management and dynamic load optimization, represent the new standard in maritime operations. Weather routing systems now seamlessly integrate with propulsion management, while IoT sensors enable predictive maintenance that prevents costly downtimes.

The benefits of implementing these advanced optimization solutions extend far beyond mere compliance with regulations. Vessels equipped with optimized propulsion systems demonstrate significantly reduced carbon footprints, achieving lower operational costs while extending equipment lifecycle. This holistic approach to vessel performance optimization not only ensures compliance with current regulations but positions operators advantageously for future regulatory changes.

Future-proofing maritime operations

Looking toward the future, the maritime industry must embrace a forward-thinking approach to fleet management. Today’s optimization solutions are designed with adaptability in mind, ready to accommodate alternative fuels as they become commercially viable. These systems are also prepared for the gradual transition toward autonomous operations, incorporating sophisticated data analytics for informed decision-making. The integration with fleet management systems provides a comprehensive view of operations, enabling strategic planning and resource allocation.

It’s clear that vessel operators can no longer view system simulation and propulsion optimization as optional tools for efficiency. Instead, they have become fundamental requirements for competitive operation in an increasingly regulated and environmentally conscious maritime industry. The companies that embrace these technologies and approaches today will be better positioned to navigate the challenges of tomorrow, ensuring both environmental sustainability and economic success.

If you want to learn more about system simulation for vessel propulsion architecture, watch this webinar. Our systems expert, Mike Croegaert, will take you through an approach that increases understanding of vessel performance and ensures optimal system efficiency from early in the design process.

This evolution in maritime technology and operations represents not just a response to current challenges, but a proactive step toward a more sustainable and efficient future for the shipping industry. The time to act is now, as the benefits of optimization extend far beyond immediate operational improvements to shape the very future of maritime transport.

You might also be interested in…

FACT SHEET

Simcenter Amesim for marine

CASE STUDY

MAN Energy Solutions speeds fuel injection system development by a factor of five

WHITE PAPER

Overcoming submarine design challenges