Keeping Traction Motors as “Cool as a Cucumber”

How are cucumber slices placed on the eyes during makeup analogous to motor cooling? The makeup reaction that raises the eyes’ temperature can be seen as the motor loading to meet a certain torque demand. In traction applications, to accelerate or decelerate the vehicle, which occurs over short periods involves huge amounts of energy. This results in higher heat losses, which needs to be drawn-out to prevent the motor from cooking.

Traction motors, which are mainly permanent magnet have higher power densities to lightweight the powertrain. Lightweighting reduces its electromagnetic and thermal masses. Hence, they are prone to saturation and overheating at peak loads, especially at elevated temperatures. It is important to ensure they are properly cooled since their service-life, permanent magnet, and insulation stability are temperature dependent; affecting their operational availability, and in extreme cases recalls.

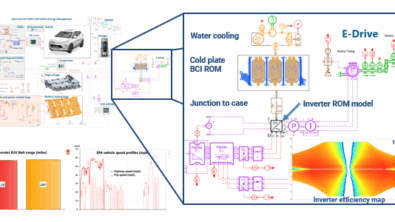

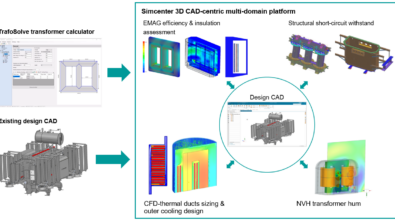

Simcenter motor design and test solutions address this challenge of reliability. System simulations are used to define the motor’s operating envelope based on realistic vehicle operating conditions. After that, rapid motor simulations are used to search for a design that meets electromagnetic and thermal FEA based performance. The final design is then analyzed in 3D CAE to ensure it meets the electromagnetic performance, it is NVH compliant and the cooling system is optimized to be effective at peak operating conditions using CFD. Testing is then done to confirm the performance.

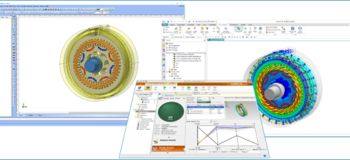

This upcoming webinar will introduce part of these solutions by optimizing the cooling of a traction motor. After analyzing the motor model in 2.5D electromagnetic and thermal FEA, the 2D model is converted to 3D and solved for electromagnetic heat-losses. The 3D model includes 3D features such as end-windings and the details of the housing. The losses are then transferred into a CFD environment, where optimization is used to improve the motor cooling.

The cooling ensures the magnets and the windings are kept below their thermal demagnetization and hotspot limits, guaranteeing operational availability at peak conditions.