KeenusDesigns: Helping Japanese engineers solve testing challenges

Simcenter™ Micred™ hardware and software powering thermal and power cycle testing solutions that prevent over-engineering of electronics

As electronics continue to shrink in size while increasing in performance, a critical challenge facing engineers is how to keep high-performance components from overheating without over-engineering them and making them larger, more complex and more expensive than necessary.

When Japanese engineers and product development specialists from the country’s biggest industrial giants encounter this challenge, they often contact KeenusDesign. A Siemens customer and reseller, this highly specialized consultancy has been helping customers conduct thermal control measurements and tackle power cycle testing challenges for almost 20 years.

To help engineers at many of Japan’s most demanding manufacturers subject their prototypes to the extremes of real-world environmental conditions, KeenusDesign leverages the Siemens Xcelerator platform and the flexibility of Simcenter™ Micred™ T3STER™ and Simcenter Micred Power Tester hardware. Combining them into an almost infinitely customizable service and product portfolio, KeenusDesign has made thermal and power cycle testing fast, accurate and, perhaps most importantly, accessible.

Electronics and temperature extremes

Whether it’s a mobile phone, internet-connected fridge, electronic home security system, advanced healthcare technology, computer-controlled internal combustion engines, or even fully electrified SUV, our 21st-century lives are increasingly powered by electronics and technology.

As electronics continue to advance, increasing in both complexity and performance demands while shrinking in size, the list of design challenges expands. Successfully addressing these challenges is crucial because electronics subject to frequent switching and temperature transience are more susceptible to failure and reliability problems. Temperature extremes and fluctuation, in particular, can greatly affect semiconductor performance and lifespan.

KeenusDesign: Thermal and power cycle engineering experts

Based in Tokyo, KeenusDesign is led by founder Junichi Tachibana, one of Japan’s top thermal and power testing experts. Following decades as a mechanical engineer, including leading thermal design efforts at Hewlett-Packard (now Keysight), his experience with thermal and power cycle design challenges, inspired him to launch the company in 2006.

Expertise in thermal, electrical and mechanical design capabilities and constraints has fueled the company’s growth and development of complementary product and service channels. Whether manufacturing and selling temperature control devices for electronic equipment thermal testing or providing testing as an outsourced service, it enjoys a trusted reputation throughout Japanese manufacturing, particularly in the automotive sector.

The company’s customer list includes multinationals such as Canon, Epson, Hitachi, Honda and Toyota, as well as many well-known public and private academic and research organizations, including the Aerospace Exploration Agency (JAXA), Industry Japan Atomic Energy Agency, Kyushu University, and National Astronomical Observatory.

A new approach to electronics testing

KeenusDesign’s approach to measuring power cycles and heat generation and dissipation differs from traditional methods in several key ways.

1. Thermal testing using small footprint chambers

Temperature testing requires specialized test chambers designed to control and monitor temperature variations. By subjecting semiconductors to precise and repeatable thermal conditions (aka temperature cycles), engineers can evaluate their endurance and ability to withstand thermal stresses. The conventional testing method in the automotive electronics field uses large chambers that provide constant-temperature baths. Comparatively slow to heat up and cool down, these chambers are also unnecessarily large for the footprint of contemporary electronics. In contrast, KeenusDesign’s testing systems are much smaller.

2. Nondestructive power cycle testing

While developing circuit boards and semiconductors, the traditional testing method is to take prototypes to failure by continually switching the power on and off. Manufacturers then take the prototype to a laboratory for disassembly to investigate the reason and location of the failure. Unfortunately, distinguishing between the failure’s cause and effect is not always possible. Fortunately, KeenusDesign’s entirely electric method is nondestructive and saves both time and money.

A Siemens-enabled niche

Unlike general-purpose test labs, KeenusDesign excels in a niche where customers require customization that most commercial solutions can’t provide. These systems either simply can’t handle the task or can’t be tailored or integrated into larger solutions as required.

To address these shortcomings, KeenusDesign turned to Siemens Digital Industries Software, leveraging Simcenter™ Micred™ hardware, which is part of the Siemens Xcelerator business platform of software, hardware and services.

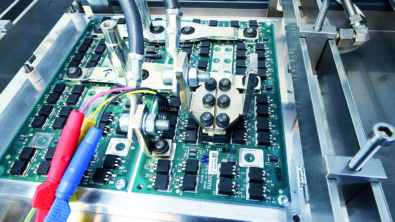

KeenusDesign conducts transient thermal resistance tests using Simcenter Micred T3STER™ hardware and power cycle tests using Simcenter Micred Power Tester hardware. Both systems ensure fast, highly accurate and repeatable results, generating actionable data that help customers identify potential design weaknesses, better understand quality control issues, and produce accurate technical product documentation.

Each Simcenter Micred product has a specific application:

A thermal transient measurement system that:

- Analyzes junction-to-case thermal resistance.

- Uses electrical parameters for measurement; no physical teardown required.

- Supports compliance with industry standards.

- Delivers thermal impedance profiles to identify failure points.

This thermal transient testing system works by rapidly changing the applied heating power of a device under test and measuring the temperature response. Collected during both static and dynamic conditions, the resulting data are used to generate thermal impedance profiles and insight into a component’s thermal behavior. Impedance profiles are extremely useful for diagnosing the thermal effects of aging, damage, failure, etc., and real-time detection of wire bond breaks, solder fatigue, die and substrate cracks. Engineers use this information to track thermal resistance changes to a specific location, as well as identify potential thermal issues such as thermal path degradation.

A power cycling test system that:

- Runs thousands of thermal cycles automatically.

- Monitors degradation over time, including solder fatigue or die attach failure.

- Separates failure causes via real-time data analysis.

As Simcenter Micred-powered tests are entirely electrical and therefore nondestructive, engineers do not need to manually disassemble prototypes after testing to determine the cause of a failure. By combining active power cycling with thermal and electrical degradation monitoring, the Simcenter Micred Power Tester hardware and software solution offers clear benefits.

- Shorter test cycles.

- Obtention of often challenging test data.

- Improved designs.

- Clear reduction in over-engineering.

- Greater reliability validation to industry standards.

Testing standards qualification

Thermal testing is critical regardless of the electronics sector, especially the automotive sector. In-vehicle electronics must withstand frequent temperature cycling, harsh vibration and humidity, automakers’ high expectations for safety-critical systems and long service lives (people are keeping their cars longer than ever, which could equal 12-15 years).

What makes Simcenter T3STER unique?

Unlike destructive thermal testing, Simcenter Micred T3STER measures the internal thermal resistance of electronic components quickly and accurately by applying an electric current from outside. As the current is applied, any internal temperature changes are recorded. This allows for repeatable, non-invasive testing with accuracy up to 0.01°C. The system is ideal for validating heat transfer paths, materials and packaging designs without cutting into the component.

Using its Siemens-powered test environments, KeenusDesign can prove that components meet or exceed global and industry standards. This is critical as many electronics companies buy products or services from KeenusDesign to qualify components to commercially required standards. Simcenter Micred T3STER, for example, can test components against a variety of standards, including:

- JEDEC standard JESD51-1 Static method: Tj and Rth measurements

- JEDEC standard JESD51-14 compliant: Thermal resistance testing standards

- AEC-Q100 and AEC-Q200: ICs and passive components

- AQG: Automotive qualification guidelines

“Simcenter Micred T3STER is the only instrument capable of measuring thermal resistance with this high of precision using the static method.”

Junichi Tachibana, Founder, KeenusDesign

A source for both products and services

KeenusDesign is both a Siemens customer and a Simcenter Micred hardware and software reseller in Japan, offering both products and services. Engagement and measurement details vary depending on the customer’s timeline, budget, internal resources, and measurement requirements. If a conventional solution cannot generate the necessary measurements, KeenusDesign has a reservoir of experience and knowledge, which expands with each project, to customize measurement solutions using in-house equipment and jigs.

KeenusDesign monetizes this knowledge by building custom jigs that create precise environments that ensure high repeatability for customers that may need compliance with industry standards. Products like this are typically sold to customers that have the internal resources and capabilities to operate their own testing programs.

Distinct from this population is a large group of companies and organizations that either,

- Do not conduct any thermal testing,

- Use simple thermocouple-based measurements that may lack industry-specific accuracy, or

- May understand the importance of testing, but lack the budget, equipment or internal engineering resources to run their own tests.

An unmet need

KeenusDesign identified this unmet need in the market. Using its Siemens-based lab and the functionality and flexibility of Simcenter Micred T3STER and Simcenter Micred Power Tester, it launched thermal testing and power cycle testing-as-a-service. In addition to access to the Micred technology family, customers also gain access to a team of domain experts, decades of experience and institutional knowledge.

”We solve challenges that are difficult to solve with other equipment, but it is the results that customers need, not the test environment. Depending on the test’s objective, we modify as needed to suit specific tests and provide an optimal, efficient test environment for our customers. We often find that we can help our customers when our competitors cannot.”

Junichi Tachibana, Founder, KeenusDesign

Thermal analysis challenges in the automotive industry

Automotive is one of KeenusDesign’s most important and promising industry categories. Which makes sense as the amount of electronics packed into vehicles grows with each model year. As this electrification trend grows—irrespective of engine type—automakers and parts suppliers must address the heat generated by in-vehicle parts and sub-systems such as engine control modules, circuit boards and materials. Since heat can reduce their performance and lifespan, reliability standards are strict.

It shouldn’t be surprising then that the need for power electronics testing is rising. To experimentally verify predicted lifetimes of electronics, more and more auto parts suppliers are performing thermal and active power cycling tests during product development so they can meet the quality standards demanded by big automakers.

“Quality standards for vehicle electronics are the highest so testing requirements are greater. Thermal testing requirements, for example, in the consumer camera market are not severe, but if they are selling to an automotive manufacturer, quality expectations and thermal reliability testing requirements are higher.”

Junich Tachibana, Founder, KeenusDesign

| Did You Know? Testing requirements for the automotive industry are strict. In fact, one of the primary standards organizations, The Automotive Electronics Council (AEC), was originally created by Chrysler, Ford and General Motors in 1993 to establish global parts-qualification and quality-system standards for automotive electronic components that would be common across their respective supply chains. |

Customer spotlight: Denso’s thermal testing solution

One of the largest auto parts suppliers in the world, Denso Corporation’s vast product catalog ranges from engine components and climate control systems, to airbag systems and pre-crash radar systems.

While it had been conducting thermal testing of its printed circuit boards before meeting KeenusDesign, its then-testing setup produced a 7°-10°C margin of error across a maximum measurement range of -40°C to +150°C.

Compounding the inaccuracy and limitations was the reluctance of Denso’s semiconductor suppliers to share technical details so that Denso engineers could eliminate at least one of the “thermal unknowns” from their design work. The result was over-engineering in the final designs to guarantee future performance and reliability.

When a customer requested measurements to meet JEDEC and JESD5 standards certification, it was clear that Denso needed a much better testing system. Relief became clear when Denso engineers saw a Simcenter Micred T3STER demo at a trade show.

What is PELNUS

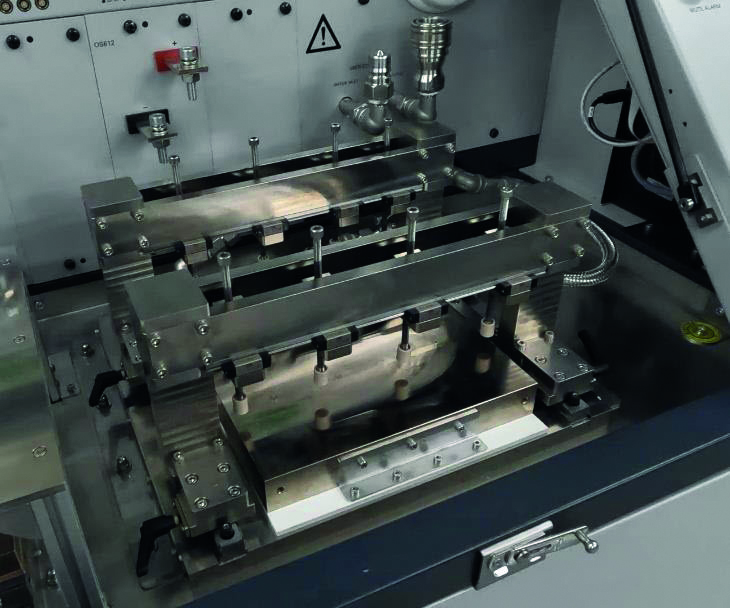

PELNUS is a compact temperature controller developed by KeenusDesign for thermal resistance testing. Originally developed for Denso Corporation, it provides tight thermal control and mechanical pressure, allowing engineers to simulate real-world environments in lab settings.

Highlights:

- Fully compatible with Simcenter Micred T3STER

- Precise and rapid control from -55°C to +250°C

- Supports JEDEC-compliant pressure application

- Enables repeatable test conditions with minimal operator involvement

Denso needed more than just an excellent thermal resistance measuring device however; the engineering team needed a total solution. Leveraging experience designing temperature-controlled environments with compact footprints, KeenusDesign built a turnkey desktop temperature controller featuring a -55°C to +250°C temperature range and a tiny margin of error of ±0.1°C.

Denso was thrilled, calling it “an absolutely unique measurement device” while singling out KeenusDesign as a rare presence in Japan due to its understanding of both thermal and mechanical design. After seeing the controller’s success inside Denso, KeenusDesign decided to market it to other Simcenter Micred Power Tester customers as a standalone product called PELNUS.

Cost of over-engineering

Over-engineering is one of the hidden costs of the uncertainty and unknown that Denso wanted to reduce. When engineers lack precise data on how a semiconductor or circuit board will perform under thermal stress, they typically respond by including a margin of error in the form of thicker materials, higher-rated components and even heat sinks.

The absence of critical thermal data can lead to “better safe than sorry” decisions that, while understandable, will also add:

- Cost to every commercially produced unit.

- Weight and bulk to final products.

- Engineering complexity that can slow development or increase maintenance costs.

To maximize effectiveness and cost-savings, thermal countermeasures must be integrated in the early stages of design. The longer it takes to discover a problem, the greater the cost of fixing it. Denso avoided this and eliminated future excess by having Simcenter Micred test data that provided certainty and confidence.

What’s next for KeenusDesign

KeenusDesign’s close relationship with Simcenter’s sales, engineering and support teams has been vital during its first two decades of growth. But what’s next?

KeenusDesign plans to install many more Simcenter Micred Power Tester solutions to deliver quick thermal testing results, in addition to adding analysis and simulation solutions so engineers can quickly access initial test results and improve their prototypes.

An adjacent plan is to connect the company’s test systems to Mendix™ software, a low-code application platform that is also part of the Siemens Xcelerator business platform. Customers will be able to check test status and results, then download raw data and process it with their own Simcenter Micred analysis software. By transforming lab data into accessible insights, it will also add a new revenue stream to KeenusDesign’s services business.

Longer term, Tachibana is confident that the flexibility of the Simcenter Micred T3STER and Simcenter Micred Power Tester equipment and its adaptability to various manufacturing processes will expand the markets into which his team can sell solutions.

“Siemens products are the de facto standard in Japan and have tremendous credibility. We aim to provide cutting-edge solutions that enable our Japanese customers to succeed and become top players in global markets. Since all our customers are world-class businesses, they demand safe and accurate measurements, and it is important that we have a way to achieve this. We have earned our customers’ trust by using this equipment.”

Junichi Tachibana, Founder, KeenusDesign