More efficient testing in 4 easy steps – Simcenter Testlab Workflow Automation (TWA)

R&D teams have been testing their products for decades, but being more efficient has never been such a critical issue. Every major OEM has been announcing their desire to reduce the number of physical prototypes, sometimes even to zero. This poses a huge challenge to the simulation teams, for sure, but what about testing? Having even more limited access to the object under test means that testing has to become more efficient and results need to be obtained faster, earlier and in a smarter way.

That’s precisely why we’ve created Simcenter Testlab Workflow Automation (TWA) – a tool that will make your tasks more efficient and deliver the required results much faster.

Step 1 – Understand what TWA is

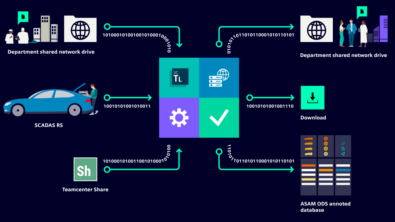

Simcenter Testlab Workflow Automation, a newest additional to the Simcenter Testlab 2406 release, is a collection of services designed to automate data retrieval, processing and storing or publishing of the results.

TWA automatically retrieves, processes, and publishes data coming directly from Simcenter SCADAS hardware, shared network drives or Teamcenter Share, or any Siemens cloud collaboration solution.

Simcenter Testlab Neo Process Designer, running on a server, then automatically post-processes all that data. You can then immediately publish results to Simcenter Testlab Data Management or download to a shared network drive.

Step 2 – Democratize access to data analytics

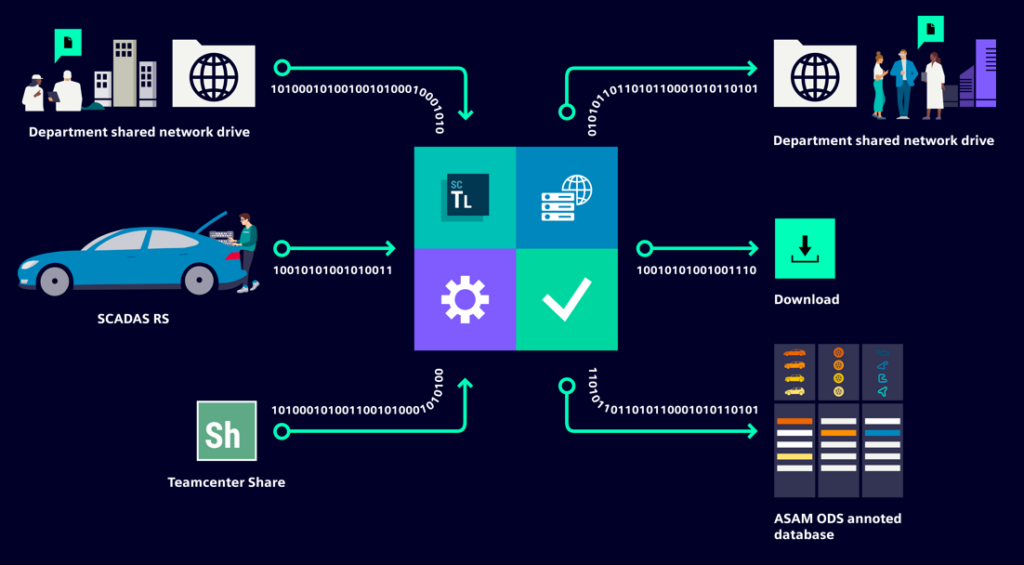

Big companies often end up working with different software and hardware suppliers. This often results in challenges when comparing results calculated by different NVH or Durability applications – simple FFT settings such as the window or spectrum resolution can have a huge impact on your final result.

By deploying a centralized processing server, different departments can continue to use their existing data acquisition hardware. The only difference is that all the measured results will be automatically analyzed using the same processing definitions in an extremely efficient way. There is no longer a need to question the number of used bins or the overlap percentage. Just store your HDF, ATFX or S3T files (or any other file format that Simcenter Testlab natively supports) on an agreed-upfront shared network drive and TWA will do the rest.

Processing huge quantities of measurement data coming from different hardware vendors in a automated, unified and efficient way has never been easier.

Step 3 – Get your results faster

Finishing a measurement campaign only to realize at the end (or worse, days later) that something should still have been measured, have you ever been there?

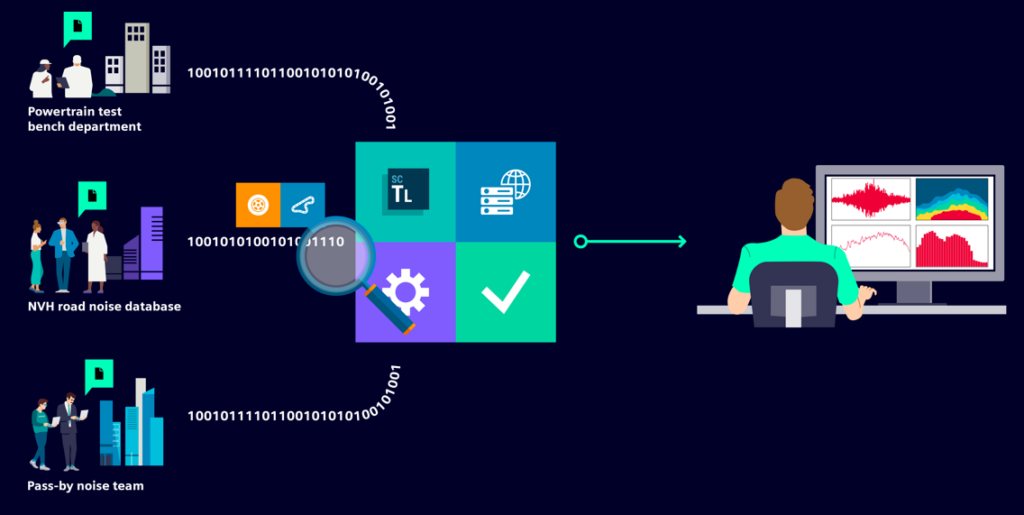

The state-of-the art connectivity features of SCADAS RS allow to setup a scenario where the object under test (a vehicle, aircraft, bridge or washing machine) is being measured standalone at a remote location. You can now remotely access test data that is currently being measured on a SCADAS RS system on a vehicle out at the track.

Every measurement gets processed and the results are immediately stored centrally – all while the test driver is still completing all the maneuvers. Engineers in the office and on-site can review and determine if they have the data they need and eliminate the need for future re-tests.

Step 4 – Become more efficient with Machine Learning and AI

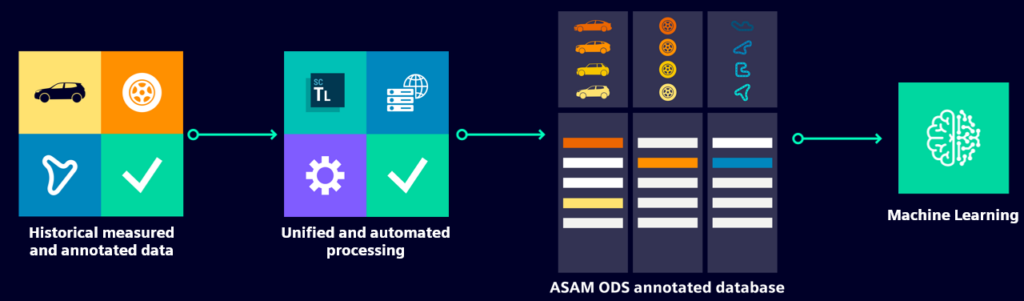

The final step in increasing efficiency is linked to data. Or specifically, big data. Every industry in the world is currently being disrupted by Machine Learning, and physical testing is not an exception here. But in order to even consider using test data and results as input to AI, you have to take care of two things:

- Machine Learning requires large quantities of data on input. Can you find back the relevant and correctly labeled results in an easy and efficient way?

- Training data has to be consistent – differences in how the results were calculated can significantly skew the inference step and affect your predictions

Do these ring a bell? Simcenter Testlab does offer a unique combination of a centralized data management and processing solution, where every consistently processed result can be automatically published to a central ASAM-ODS server.

All results are annotated and can be easily traced back, which means that one of the biggest hurdles of Machine Learning: data collection and labelling, is done in a very efficient and quick way.

And this brings us to the end of the Simcenter Testlab Workflow Automation introduction. Have a look at all the other great content that is part of the Simcenter Testlab 2406 release!