How to acquire realistic road load data

Kiddy carts are top toys. Kids just love them! They let it race over obstructions, bumps, dive down a steep slope or fly over obstructions. Anything is possible. Sand, water, dirt, the back of the dog … these toy cars seem to withstand any challenge!

What customers expect

As you can read in the blog post: 5 reasons why superior vehicle durability matters, this is precisely what customers expect from the real-life versions of these vehicles, such as passenger cars or trucks. But how do you design a durable vehicle? How do you know how many potholes, mud puddles, bumpy gravel roads and kilometers of highway driving your car or truck can withstand? The key to success is to capture precise road load data in the anticipated market or on proving grounds. Doing so, you can gain a precise understanding of the loads that your product will undergo during its anticipated lifetime. This vital load information is also key input for downstream computer-aided engineering (CAE) and laboratory testing activities.

Road load data acquisition sounds easy, right? Not necessarily.

Most RLDA testing teams are under tremendous pressure to deliver high-quality data as fast as possible for as many vehicles as possible. Using complicated and time-consuming traditional systems can make their life a bit stressful at times.

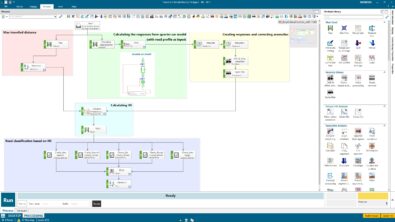

That is why more and more teams are switching to state-of-the-art methods, such as the advanced Simcenter RLDA solution from Siemens Digital Industries Software. It not only enables you to acquire reliable data under extreme testing conditions, but it also includes embedded universal signal conditioning for easy setup of various test types. Compact and easy-to-install, it interfaces with a wide range of analog and digital sensors, and is designed for flexible channel count measurements.

The solution is technician friendly, offers an unparalleled connectivity and provides accurate measurements right-first-time, seamlessly guiding both novice and experienced users through the entire durability acquisition process

Both OEMs and suppliers benefit from this solution. Check out the costumer success story of Nissan Technical Centre Europe and see how they enhanced durability testing with the Simcenter solution. Or read how Faurecia Emissions Control Technologies builds clean, long-lasting exhaust system conducting an efficient and successful RLDA campaign.

Regardless of how kids (mis)use their kiddy carts, the expectation of our ‘real’ customers are achievable. Because designing a durable vehicle … you can do that!

Watch the on-demand webinar:

Measure vehicle response to gain a precise understanding of the loads

Efficient road load data acquisition

that products will undergo during their anticipated lifetime

What you’ll learn:

- Acquiring realistic load data in the most cost-effective way

- Optimizing your acquisition process obtaining high-quality data as fast as possible, for as many vehicles as possible

- Making durability engineering an integral part of your vehicle development process

Check out more Simcenter integrated solutions for Strength and Durability.

Comments

Comments are closed.