“Honey, I’ve done the laundry” – Master 9 household chores like a CFD simulation pro

“Yay! Housework!”

no one ever

Hands on heart, who loves doing the household chores? Well, I thought so! But here’s the thing: Can things not become more exciting if we learn more about them? I mean even the most tedious things? Might they not be less mind-numbing if only we gave them a chance? Might there not be some hidden beauty in doing the laundry – if only we understood the chemistry behind them? Isn’t there some amazing particle physics involved in vacuum cleaning? Imagine how satisfying it would be to look inside the dishwasher after we packed it and enjoy watching the curious paths of the water jets as they clean the dishes? And who has not dreamed of looking straight under the lawn mower as the blades hit the grass – but without risk to our safety?

“Wise men say, only fools rush in”. Therefore, before we get our hands really dirty this Saturday morning, let’s take a step back!” said the simulation engineer in me. Rather than it getting all too hectic, let’s tackle a few household chores the CFDish way. And what a busy day it should become…

Doing the household chores like a CFD simulation pro

Mow the lawn

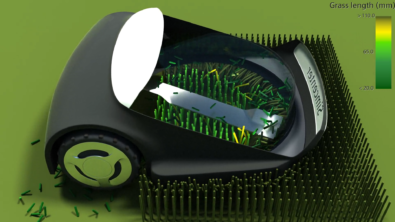

Saturday morning 8 a.m. No better time to kick-off the lawn mower. Luckily, my colleagues Oleh and Stephan helped me out with this one, which is entirely silent and autonomous.

Strictly speaking this is no Computational Fluid Dynamics CFD. This is a Discrete Element Method simulation. More precisely it is a mesh-free DEM. It simulates mechanical behavior of discrete particles, interacting with the solid walls – of the mower, the floor and the blades. The grass is modeled with a Flexible Fiber model – several capsule particles attached to each other. These Flexible Fibers use a breaking mechanic model to split up on a certain force applied. As the air is not modeled in this rapid mesh-free approach, we cannot capture air based-dampening of the moving grass. To prohibit unphysical behavior, a dampening force can be applied.

Cutting edge technology to simulate the grass cutting process, analyze particle distribution, reduce spill and catch all fibers and even predict the cutting torque.

But still, if you wanted to take the air into account, you can add one-way coupling, so the air influences the particles, or even two-way coupling, so the air is also affected by the particles! But I will come to that later as I don’t have time right now…

Prepare breakfast for the kids

8.30 a.m. …as a kid starts screaming. “I am hungry!” “Me too” goes another one. And 1. Well probably time to prepare breakfast for the kids. What? No fresh bread? No worries kids, daddy’s got this.

Those moments when Conjugate Heat Transfer modeling comes in handy:

Oh, the kids are thirsty as well? Gimme a second. Oh no, the faucet is leaking…

Fix the faucet

9.00 a.m. We’ve all watched “Home Alone”. Since watching the Wet Bandits in action, it should be clear that water damage is no fun. And so, I strongly recommend, that every CFD engineer study the interior of the faucet before getting their hands on the real twin! I believe this multiphase VOF (Volume of Fluid) CFD by our partner AEROTHERM gives you all the necessary understanding to really fix the faucet (I am not responsible for any damage though).

What’s in it – apart from water: Volume of fluid (VOF) multiphase simulation of both air and water. But the kids are thirsty so this better run fast: Use Adaptive Timestep and MHRIC scheme for faster turnaround time add our beloved Adaptive Mesh Refinement – meaning you only have a fine mesh where and when you need it. And here we go, water flows again!

Washing the Laundry

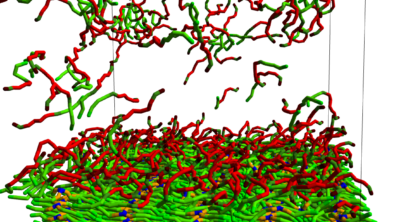

9.35 a.m. Kids are done with breakfast, chocolate sauce has done its job on their pajamas as reliably as ever. This is serious stuff and I will need some help from our Computational Chemistry friends here!

Time for washing laundry at low temperatures with computational chemistry: Dissipative Particle Dynamics DPD simulations in Simcenter Culgi will do the trick: accurate simulation of coexisting solid and fluid phases and the phase transition with minimal parametrization effort. Look how the detergent penetrates and continuously erodes the solid stain and transports it away from the stain’s surface: this is what happens during successful washing on a molecular scale.

Eat this, chocolate stain!

While the washing runs, I rush back up to clean up the mess at the kitchen table.

Do the dishes

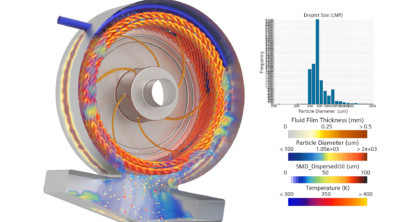

10.00 a.m. Honey, I’ve done the dishes (ok, it was my colleague David and a he did it a little CFDish admittedly)! Anyway, I believe, no machine is more underestimated than a dishwasher! I mean, seriously: Ever been on vacation in an apartment without one? Ever had to wait for a replacement, when yours got broken? This is it. Vacation’s over! No, I never want to go back to times where you had to hand-wash the dishes. And even more so, I love this virtual insight into that beloved machine:

Here, hybrid multiphase is your friend: several interconnected models with automatic transitions to the locally most efficient one describe the liquid and the gas phase. While the Volume of Fluid simulates bigger reservoirs of liquid, the Fluid Film model captures effects like wetting surfaces and Lagrangian multiphase captures ballistic droplets. This is doing the dishes with maximum efficiency, but don’t forget to add adaptive mesh refinement.

Oh quick side note, with Simcenter STAR-CCM+ 2406 we have pushed this even further!

Gently remind the kids to brush their teeth

10.30 a.m. If you have kids, you’ll know what I mean. We have all been there! Maybe this DEM with our beloved flexible fibers and erosion modeling by Oleh will help:

Vacuum Clean

10.45 a.m Lawn cut. Faucet fixed. Kids fed. Dishes done. Teeth clean. Time to get rid of some bread crumbs, pet hair, Lego bricks and alike. Time for the virtual vacuum cleaner. Oh, DEM with flexible fibres comes in handy again (Who would have thought that lawn mowers, toothbrushes and vacuum cleaners have so much in common!). But this time fully coupled with aerodynamic forces. For a better cleaning result!

Dry the laundry

11.00 a.m. Laundry is clean. Time to dry. I could spend hours looking at this one. They are so mesmerizing. This is what I consider brilliant postprocessing of laundry.

The simulation: Discrete Element Method, again. Oleh, again. But this time with user defined particle agglomeration! New feature! I know it’s hilarious. Dry your eyes, mate!

Bring down the residuals

11.55 a.m. Almost done. Last action before we call it a day- as for every good CFD engineer: Bring down the residual waste. And now – time for a relaxing weekend.

Saturday 12 p.m. I’m outa here! Weekend, honey!

Wait. What? The real twin? Hmmm…

The dishes will wait. Life won’t