The art of the automobile: why cars look the way they do (and how we make them better, faster) – Geometric Deep Learning for CFD

Dad, why do cars all look the same?

It was a question I’d almost faked for a blog post, a little anecdote to kick off a discussion about engineering. But then, in a moment of paternal overconfidence, I actually asked my daughter. Her response was immediate, emphatic, and delightfully dismissive of my premise:

They are not all the same, and some are much nicer than others!

And just like that, my carefully constructed blog narrative crumbled. But in its place, a far more interesting story emerged – one that perfectly encapsulates the delicate dance between engineering necessity, aesthetic desire, and the relentless pursuit of efficiency.

Challenge design constraints without limiting creativity

She’s right, of course. To a child’s eye, the nuances are clearer; the subtle curves and bold lines that differentiate one model from another are distinct. Yet, from an engineer’s perspective, there’s an undeniable truth to the underlying similarities.

Think about it: a car needs to transport at least four people comfortably, navigate diverse road conditions (and perhaps a little off-road adventure), carry a substantial amount of luggage – say, 200kg – and adhere to a labyrinthine web of global safety and environmental regulations. All while being capable of high speeds without guzzling fuel or draining batteries too quickly.

These aren’t suggestions; they are fundamental constraints. They dictate the overall footprint, the height, and the general silhouette. They demand a certain amount of crumple zone, a specific window visibility, and a minimum ground clearance. It’s a design brief that, at first glance, seems to squeeze out all possibilities for genuine innovation or visual flair.

This is where the magic, and the challenge, truly begins. Within these tight parameters, automotive designers and engineers are constantly striving to create something both beautiful and incredibly efficient. And here’s a secret: a huge part of that efficiency comes down to how a car interacts with the air around it. Aerodynamics.

Rethink aerodynamic exploration beyond traditional CFD

For years, optimizing a car’s aerodynamic performance was a painstaking process. Imagine a designer sketching a new concept for a car’s rear spoiler, believing it wouldn’t have a too big impact on the drag.

To verify this, engineers would set up a Computational Fluid Dynamics (CFD) simulation. This simulation would run for hours, often overnight, sometimes even over an entire weekend. You’d hit ‘run’ on Friday afternoon, cross your fingers, and hope the results on Monday morning showed an improvement. If not?

Back to the drawing board, another sketch, another long simulation.

This iterative loop, while necessary, was incredibly time-consuming and limited the number of design variations we could realistically explore. It’s important to note that even in the last decade, we’ve made significant strides, drastically reducing turnaround times by leveraging the power of GPUs instead of CPUs for these simulations. And even with these advancements, the core challenge of exploring a vast design space remained.

But the world is changing, and so is our toolkit. We now have incredible new capabilities: Geometric Deep Learning for CFD.

These aren’t just faster simulations; they’re intelligent models that leverage best-in-class neural networks to predict aerodynamic performance with astonishing speed. All of that provided in Simcenter STAR-CCM+, in a fully integrated workflow, suitable for CFD engineers, no need to be an AI expert here.

Accelerate aerodynamic prediction with Geometric Deep Learning (GDL)

So, how does GDL actually work its magic?

It all starts with the wealth of simulation data we’ve accumulated over the years. Every time we’ve run a detailed CFD simulation on a car design – whether it was a full vehicle, a new mirror, or a subtle body panel modification – that data becomes an invaluable asset. Instead of letting these historical results sit in archives, we now feed them into our AI models. This process, often called “training,” allows the neural network to learn about the complex relationships between a car’s geometry and its aerodynamic performance. It essentially distills the essence of countless full-fidelity simulations into a highly efficient, predictive model.

Crucially, this doesn’t require an astronomical amount of data. For the car we’re using in our current illustration, for instance, just roughly 40 designs were enough to train a GDL model that proved predictive across a given design space.

This relatively small dataset, combined with the power of GDL, means we can quickly build these intelligent models for new projects and start exploring.

Once trained, these AI ROMs become incredibly powerful. When a designer proposes a subtle tweak to a car’s wing mirror, or a radical new shape for its underbody, we no longer need to run a full CFD simulation for every single variation. Instead, we feed the new geometry into the trained AI ROM, and it can predict the aerodynamic performance – things like drag coefficient, lift, or even surface pressure distributions – in a matter of minutes. Not hours, not days – minutes.

This rapid evaluation capability is a game-changer for our engineering design process. Here’s how it integrates into our workflow:

- Rapid Design Exploration: When we’re in the early stages of concept development, designers often generate dozens, if not hundreds, of different ideas. With traditional methods, we could only realistically simulate a handful of these. Now, we can quickly assess the aerodynamic performance of virtually every concept, identifying the most promising ones almost instantly. This allows for a much broader exploration of the design space, ensuring we don’t miss out on innovative solutions.

- Seamless integration within Design Manager: This entire advanced functionality is delivered through a fully embedded workflow within our familiar engineering environment. This means engineers can access and utilize these AI ROMs directly within Design Manager, minimizing disruption and promoting a streamlined user experience. Whether it’s a parametric change (like adjusting a spoiler angle) or a non-parametric modification (like a completely new body shape), the AI ROMs are adaptable and provide rapid feedback.

- Fast optimization studies: This is where the speed truly shines. Optimization algorithms typically require evaluating hundreds or thousands of design iterations to find the best solution. If each evaluation takes hours, optimization becomes expensive. With AI ROMs, each evaluation takes minutes, enabling us to run fast optimization studies that converge optimal designs much more efficiently. We can quickly identify the ideal balance between performance targets (like minimizing drag) and design constraints (like maintaining a certain aesthetic or packaging requirement).

- Enhanced study types: The utility of these AI ROMs extends to any other study type we perform, including Manual, Sweeps, or Smart Sweeps studies. This means that the benefits of AI-accelerated prediction are seamlessly incorporated into existing workflows, broadening the scope of application, and further streamlining the design process. We can use them to predict global values (like drag/ lift/ aero coefficients…), surface distributions (like pressure and/or Wall Shear Stress on the hood), or even comprehensive volume fields, providing deep and multifaceted insights into a design’s anticipated performance.

This rapid feedback loop is revolutionary. It allows us to quickly identify the most promising designs that significantly lower energy consumption, pushing the boundaries of what’s possible within those inherent constraints.

Expand design exploration while preserving aesthetics

And this speed isn’t just about efficiency; it’s about creativity. When we find a design that ticks all the boxes for performance – minimal drag, optimal downforce – but also possesses that elusive “niceness” my daughter spoke of, we don’t stop there.

We can then use these same AI ROMs within our Design Manager to run fast optimization studies. We can fine-tune that aesthetically pleasing shape, tweaking its parameters to maximize its aerodynamic performance while preserving its style. It’s about finding that sweet spot where engineering excellence meets design artistry. We can explore how to make a car look sleek and sporty, yet still achieve class-leading efficiency, all without sacrificing that initial spark of design inspiration.

Just as I was about to wrap up my thoughts, my daughter chimed in again, looking at the sleek car on my screen.

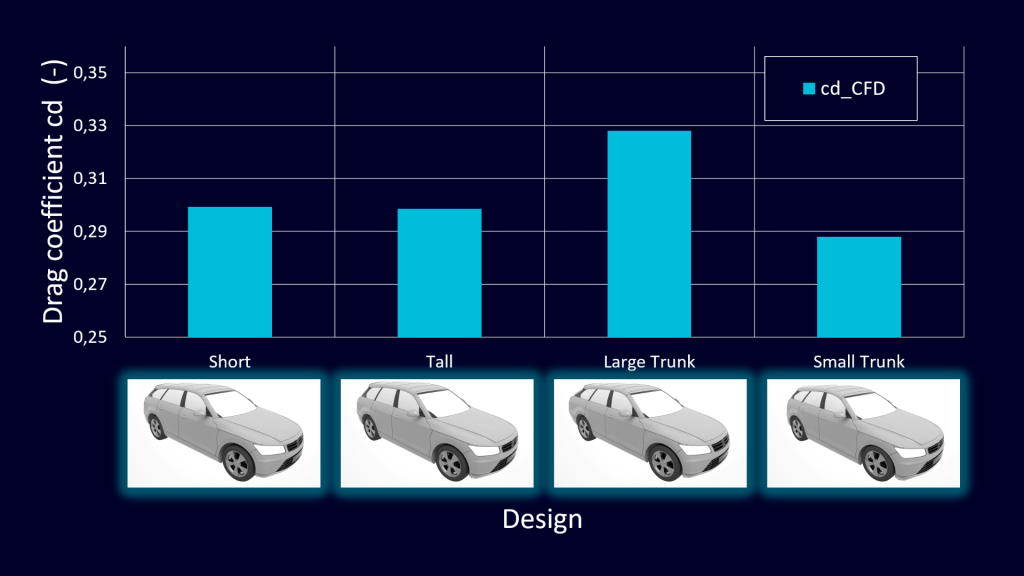

Okay, Dad, but the car you’re showing here seems really performant. This summer, I want to go camping, so we’ll need more space in the trunk for our tent and my toys. Would the car still be efficient even if you give me more space?

Her question perfectly illustrates the ongoing challenge and the power of our new tools. Yes, darling! That’s exactly the kind of design dilemma we can now tackle with unprecedented speed. We can quickly explore how increasing the trunk volume impacts aerodynamics, and then, just as rapidly, find the optimal shape adjustments to maintain efficiency, all while ensuring your camping gear fits perfectly. It’s about finding that beautiful balance.

So, while cars might share fundamental structural similarities due to their demanding functional requirements, the space for innovation, for beauty, for that subjective “niceness,” is still vast. Our new AI-driven tools are not homogenizing design; they are liberating it, allowing us to explore more possibilities, faster, and with greater confidence.

You’re right, darling.

I’ll tell her next time.

And thanks to what we do, vehicles are still going to be wonderfully different from each other, in terms of shapes, colors, and the clever ways they glide through the air.