Liberate your engineers: How smart automation crushes “donkey work” in vehicle testing

In the relentless race of vehicle testing and development, every automotive OEM faces a fundamental challenge: balancing the essential “have-to-do” validation work with the urgent need to innovate. Day in and day out, teams are tasked with validating if their vehicles meet minimum requirements for NVH, acoustics, or durability. This critical work, however, often involves highly repetitive, time-consuming, and manual tasks – what we affectionately call “donkey work.”

Imagine the hours spent manually setting up tests, sifting through endless data logs, or repeatedly executing the same test sequences. This isn’t just tedious; it’s a drain on your most valuable asset: your human talent. These are the very engineers and specialists you wish to unleash on the next frontier of mobility – adopting AI, developing sustainable solutions, or pioneering autonomous features.

The good news? You don’t have to choose. The answer lies in optimizing and automating these repetitive testing tasks. By eliminating “donkey work,” you not only slash costs but also empower your teams to focus on high-value, strategic initiatives.

The Siemens solution: Smart testing, liberated engineers

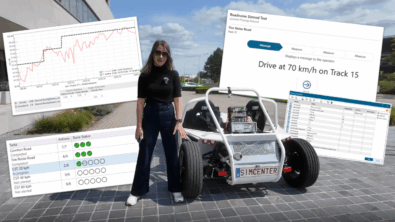

At Siemens, we understand this dilemma. That’s why we’ve developed a powerful combination of hardware and software designed to make repetitive testing work significantly more efficient, intelligent, and automated: the Simcenter SCADAS RS measurement system and Simcenter Testlab Neo software.

This integrated solution is built to transform your testing workflow, turning mundane tasks into automated triumphs. Let us show you how, through a real-world example.

Case Study: Conquering brake squeal “donkey work”

We recently partnered with a leading automotive OEM in Europe facing a classic “donkey work” scenario: repetitive brake squeal testing.

Their Challenge:

The company spent an enormous amount of time during proving ground tests manually acquiring data and painstakingly distinguishing disruptive brake noise from normal vehicle operating noise. The required detection settings vary for different vehicle types, and their old system lacked the flexibility to adapt these settings easily. Adding to the frustration, the solution was complex, usable only by specialized NVH engineers, and limited to brake tests. For other test types, they had to invest in and learn entirely new systems.

Our Solution in Action:

We deployed the Simcenter SCADAS RS hardware for robust data acquisition and Simcenter Testlab Neo software for intelligent data processing.

Here’s how this powerful duo transformed their process:

- Effortless usability: Thanks to an intuitive user interface, the system is now accessible to non-NVH engineers – drivers or technicians can confidently operate it.

- Open & adaptable: The solution is highly customizable. Users can easily fine-tune processing parameters for each unique test campaign, ensuring optimal results every time.

- Intelligent automation: With a simple vehicle instrumentation (a few accelerometers, microphones, and a brake pedal sensor connected to SCADAS RS), the system can:

- Automatically detect brake events while the driver performs maneuvers.

- Perform a smart, automated analysis to pinpoint brake squeal.

- Save raw data only for squeal events, drastically reducing data volume.

- Automatically generate a report for every detected squeal event.

Essentially, the driver just focuses on driving and braking; the Siemens solution handles all the complex detection, analysis, and reporting automatically.

The Impact:

Considering a single measurement campaign can involve over 1000 brake events, automating this sorting and analysis process delivers massive efficiency gains and dramatically reduced project timelines. Furthermore, the modularity of the Simcenter SCADAS RS and Simcenter Testlab Neo building blocks means they can be repurposed for other vehicle testing needs, eliminating the need for separate, costly systems.

The “Donkey Work” was gone.

Beyond today: The path to a smarter future

This brake squeal example is just one starting point. The same principles of automation and intelligent data processing can be applied to countless other repetitive testing activities across your organization.

By systematically eliminating “donkey work,” you free up invaluable time and resources. This newly available capacity can then be channeled into:

- Accelerating virtual prototyping: Invest in advanced simulation strategies (e.g., using Siemens’ Virtual Prototype Assembly solution) to shift testing earlier in the development cycle.

- Building your data foundation for AI: Extend your optimized processes to automatically push test data into robust data management systems, like Siemens Testlab Data Management. This creates a rich, invaluable treasury of data – the essential foundation for implementing AI and machine learning within your organization, driving predictive insights and continuous improvement.

Don’t let repetitive tasks hold your innovation hostage. Empower your engineers, accelerate your development, and build the future of mobility, smarter and faster!

Ready to liberate your team from “donkey work”? Discover how Simcenter SCADAS RS and Simcenter Testlab Neo can transform your testing operations.